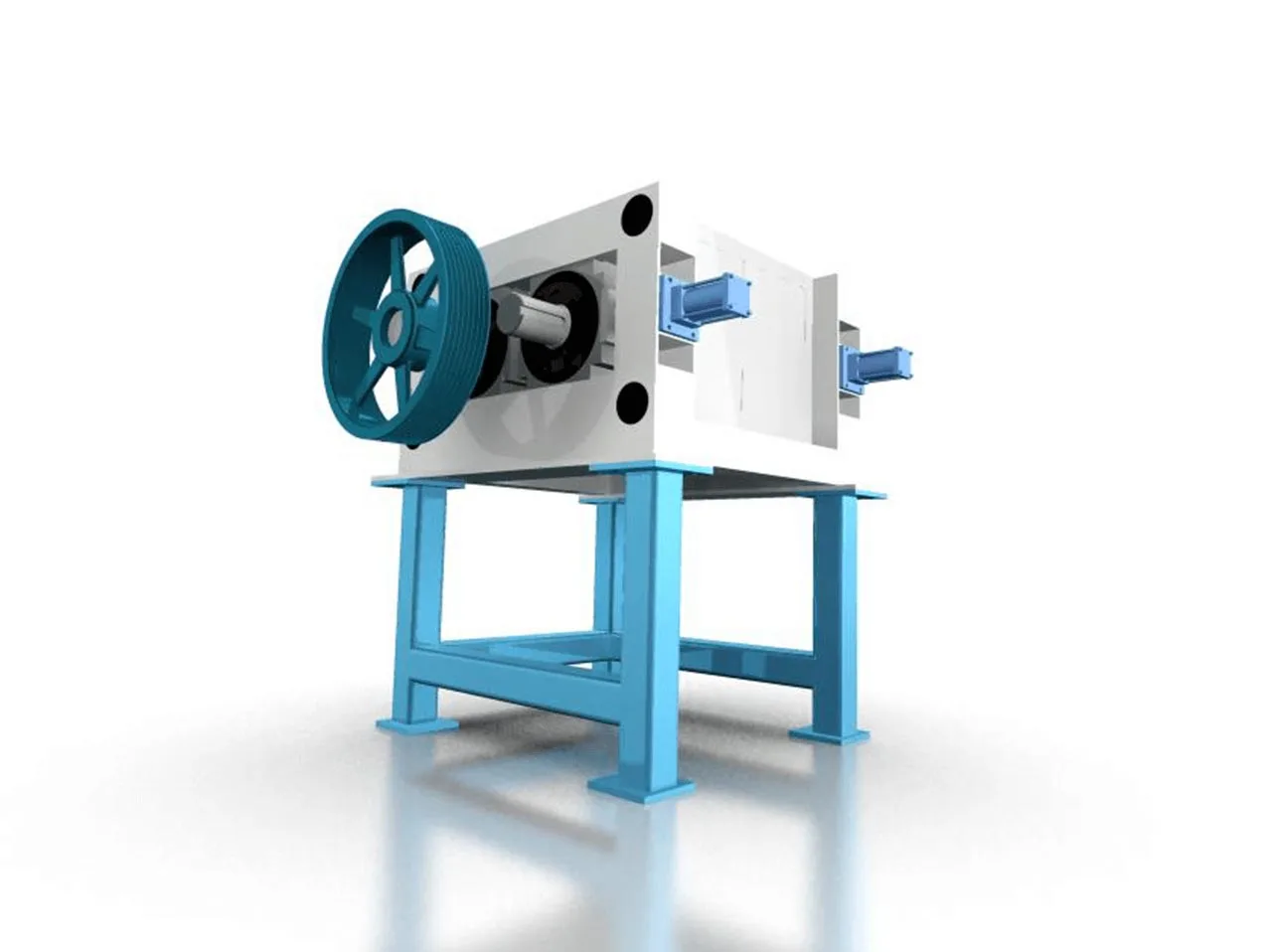

Some process needs only crushing of the material to meet either to requirement of coarse material or to feed smaller sized material to another grinder. Two hardened rolls rotate towards each other. They are kept nearer to each other by means of tether mechanical devices or with hydraulic system helps to create the pressure on the rolls and makes the crushing possible.

The larger particle of mass, cereals, pulses is pushed between the rolls uniformly spread and with a continuous rate through a separate device. A dried feed mass gives material at the bottom with reduced size or if soaked cereals or pulses, give you the material in a flake form.

Models |

Main Motor (HP) |

|---|---|

|

Flaker 600 x 1000 |

150 HP |

|

Flaker 750 x 1000 |

Flaker 750 x 1000 |

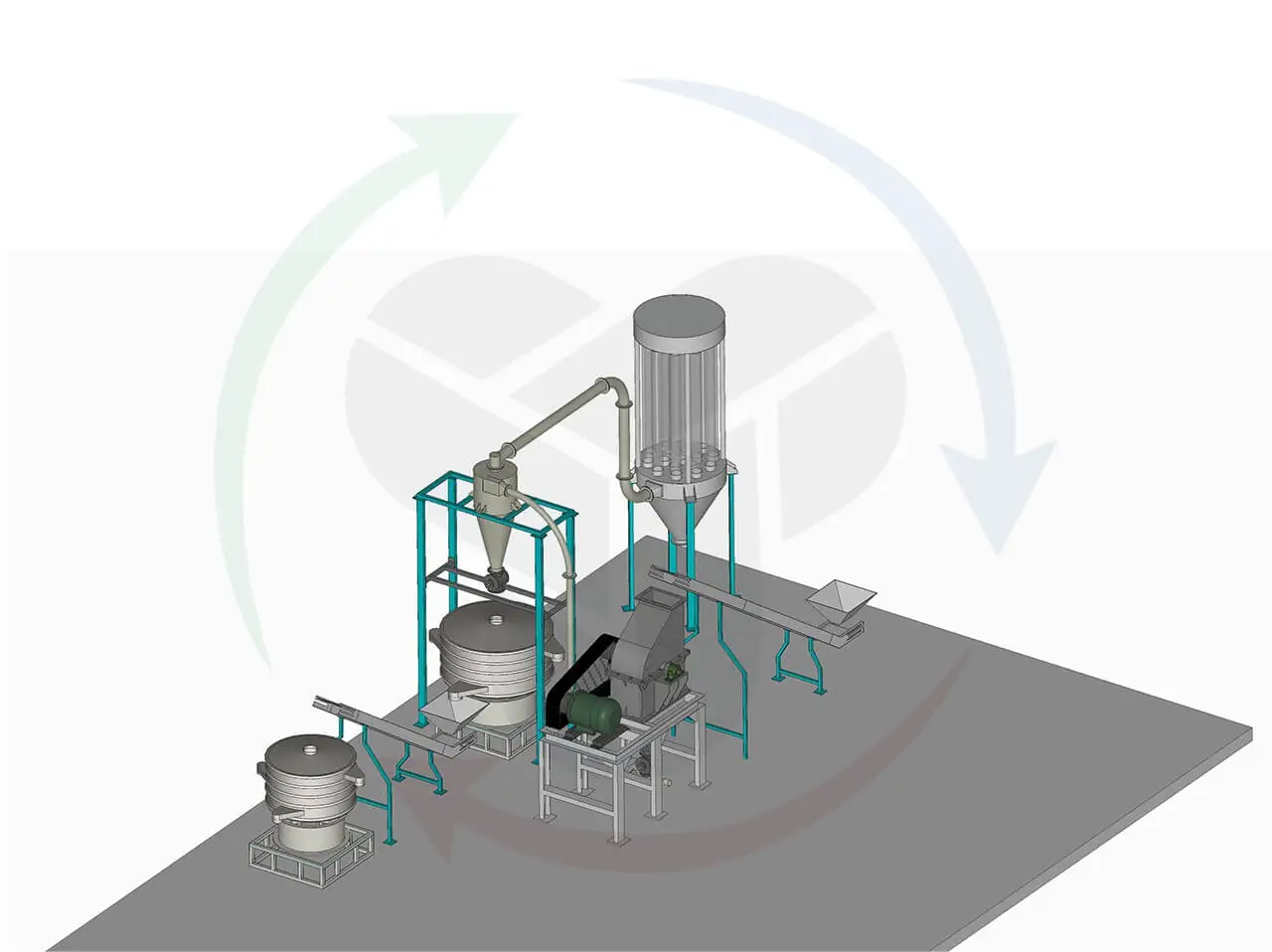

A unique equipment to handle the mass that is most difficult to grind. It gives the desired fineness with a very high capacity.

A unique equipment to handle the mass that is most difficult to grind, It gives he desired fineness with a very high capacity and that too at lower power consumption.

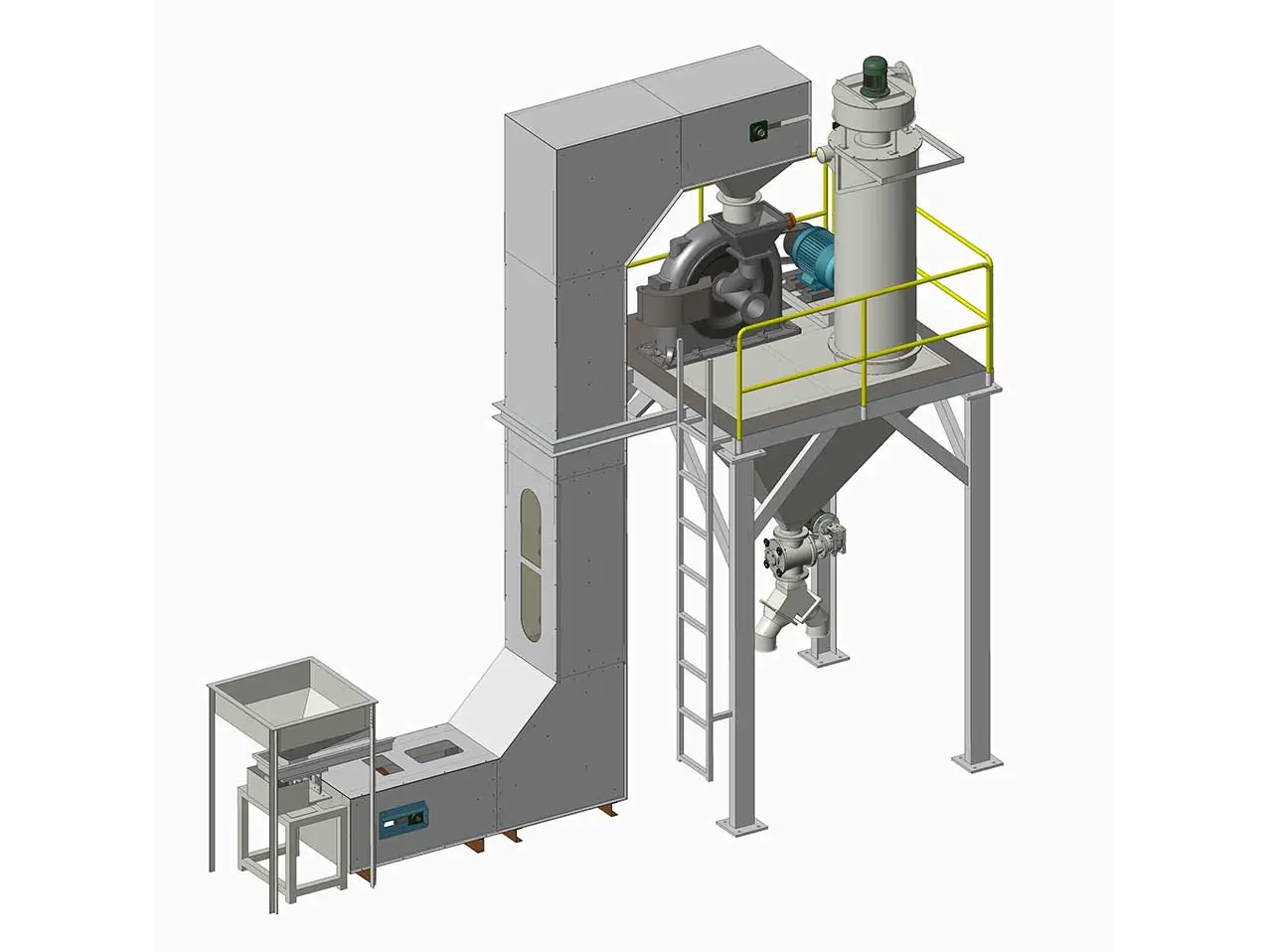

Hammer mill is used for the materials that are grounded on the impact of the hammer.

The machine is designed for finer mesh grinding of different materials, which are heated during grinding.

Ultra Dual mill having 2 rotors fitted with pins for high powder fineness. Specifically, it is used for coarse production.

A good range of batch type ball mills to crush even the hardest materials like quartz, topaz, ceramics, silica etc.

Some process needs only crushing of the material to meet either to requirement of coarse material or to feed smaller sized material to another grinder.

REQUEST

INFORMATION