- Home

- Products

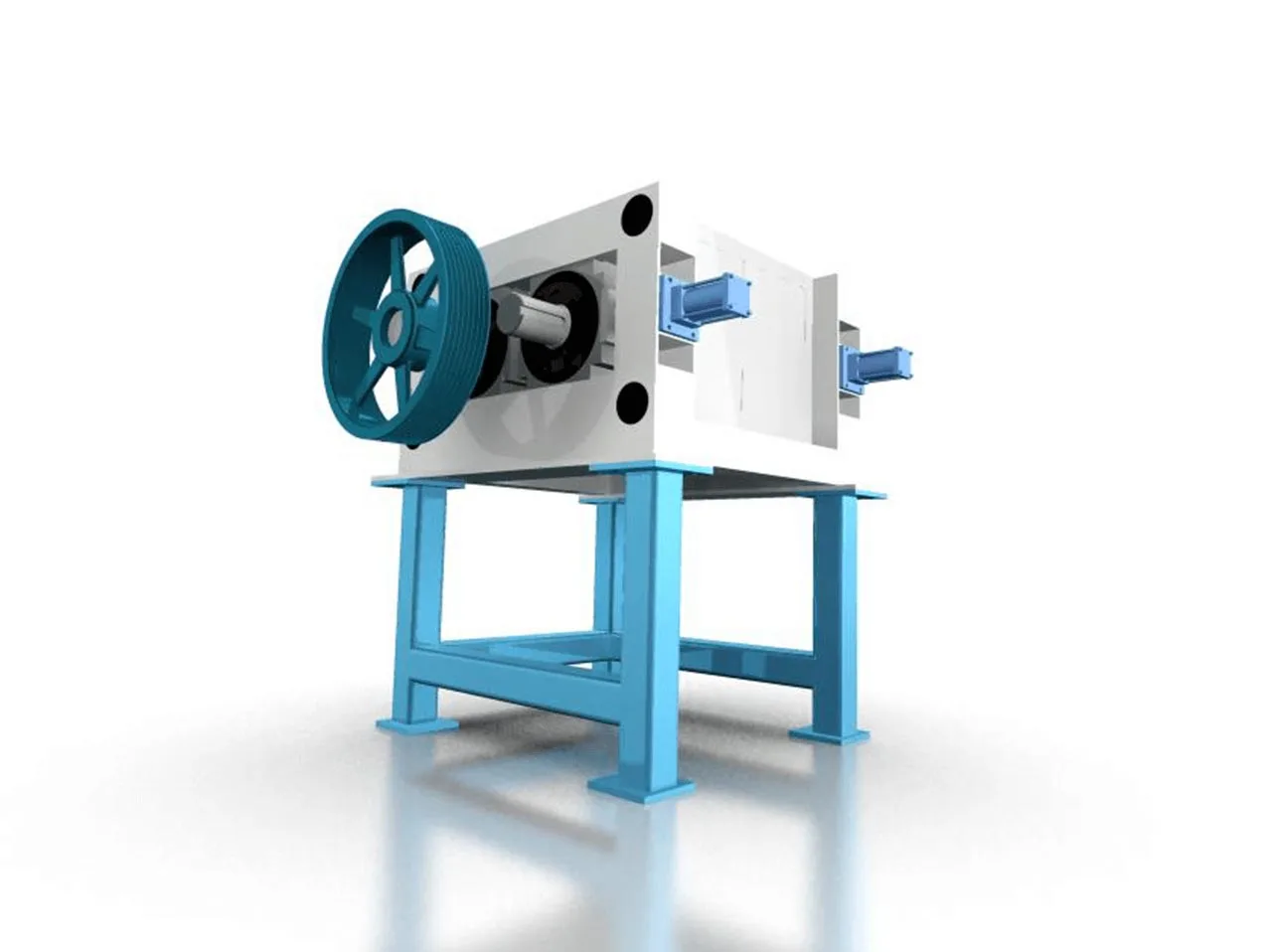

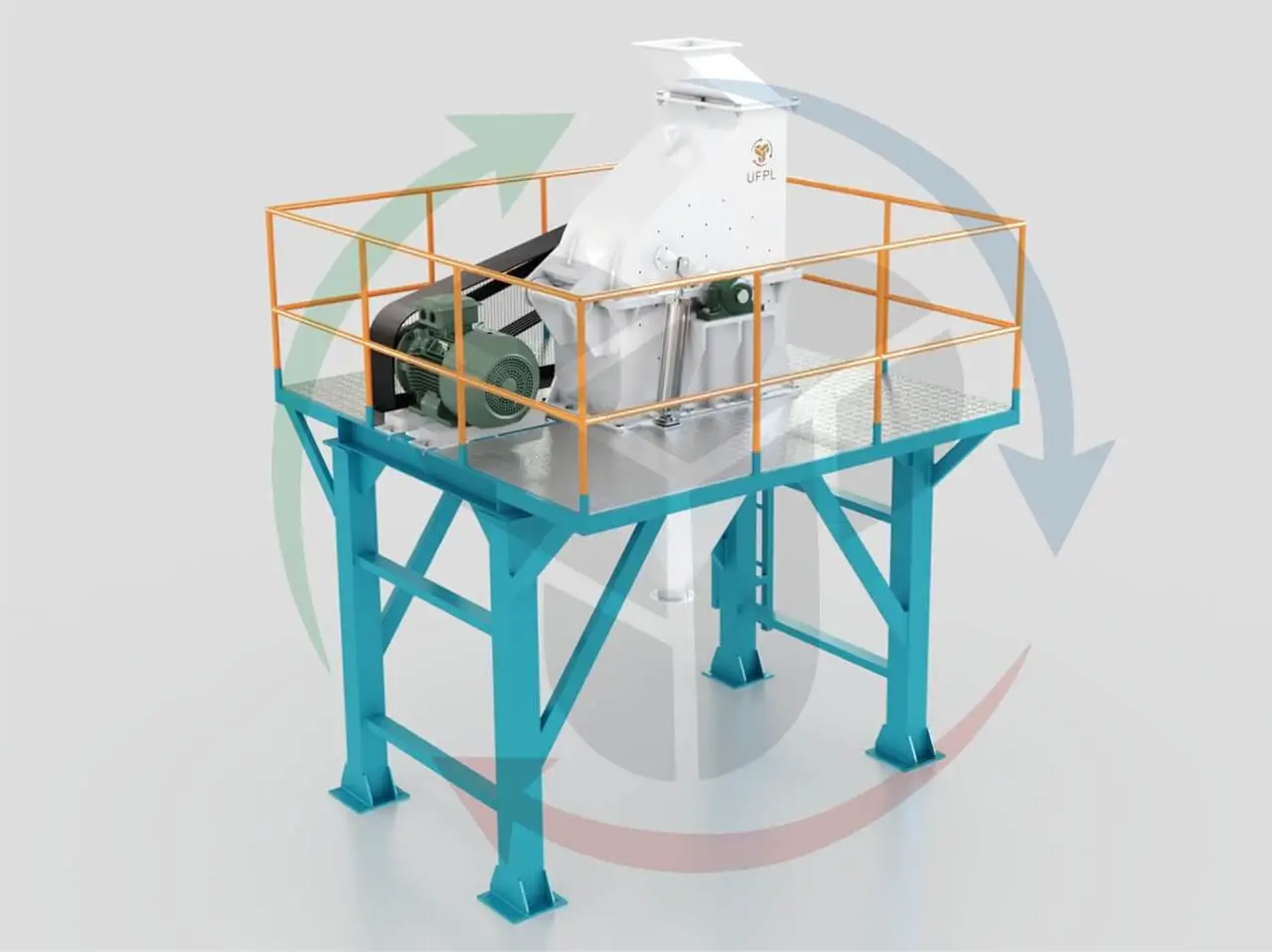

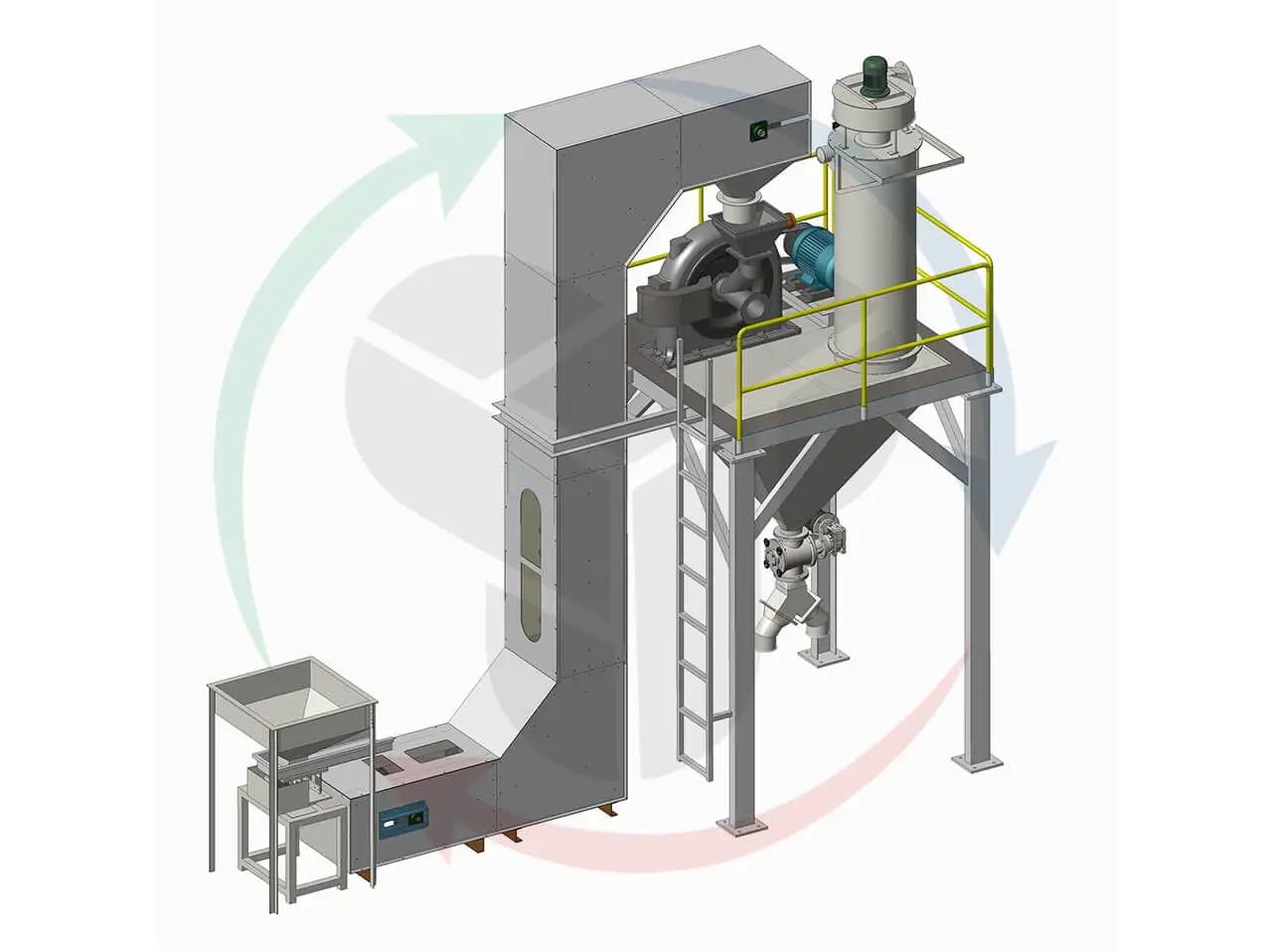

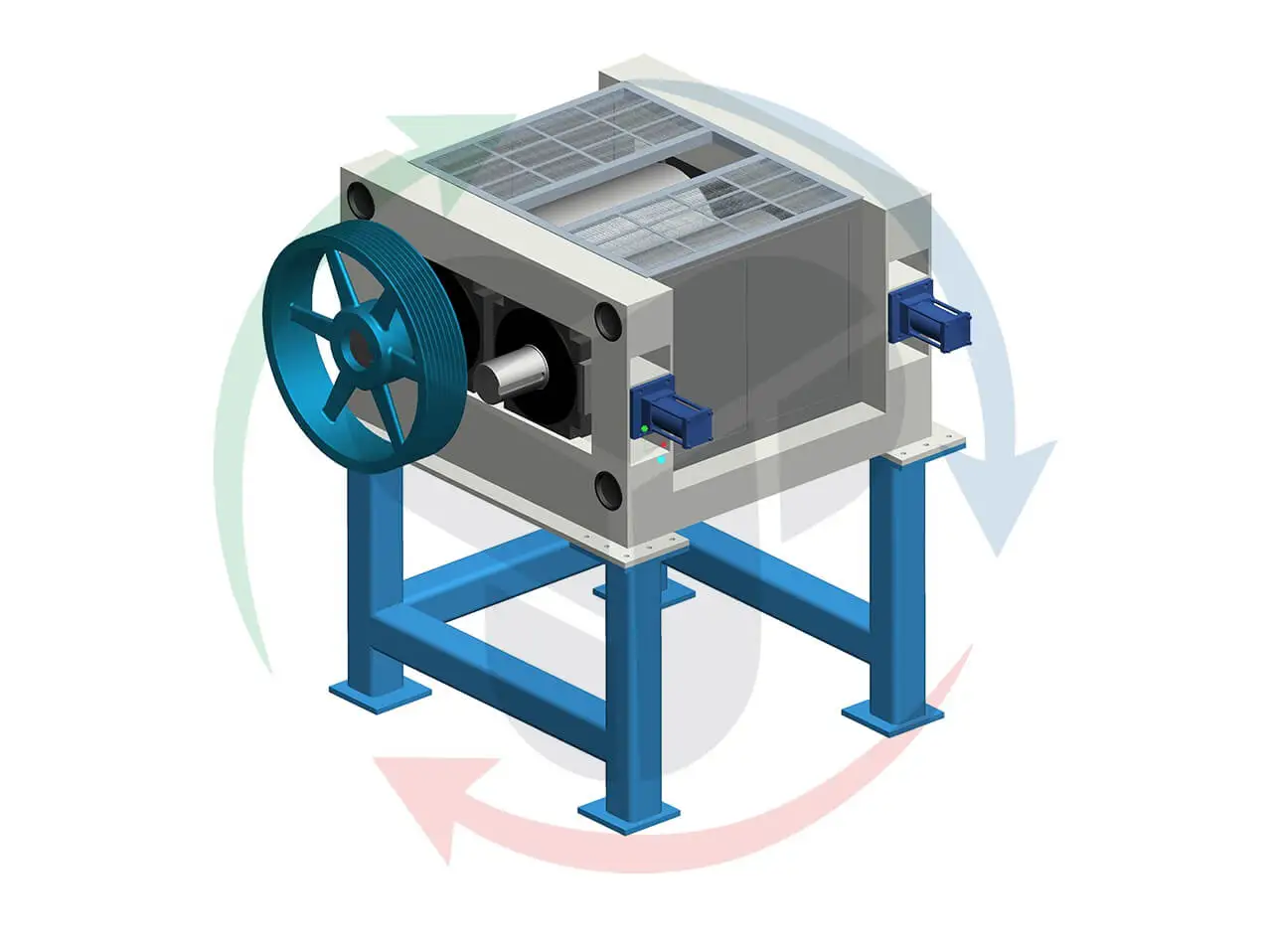

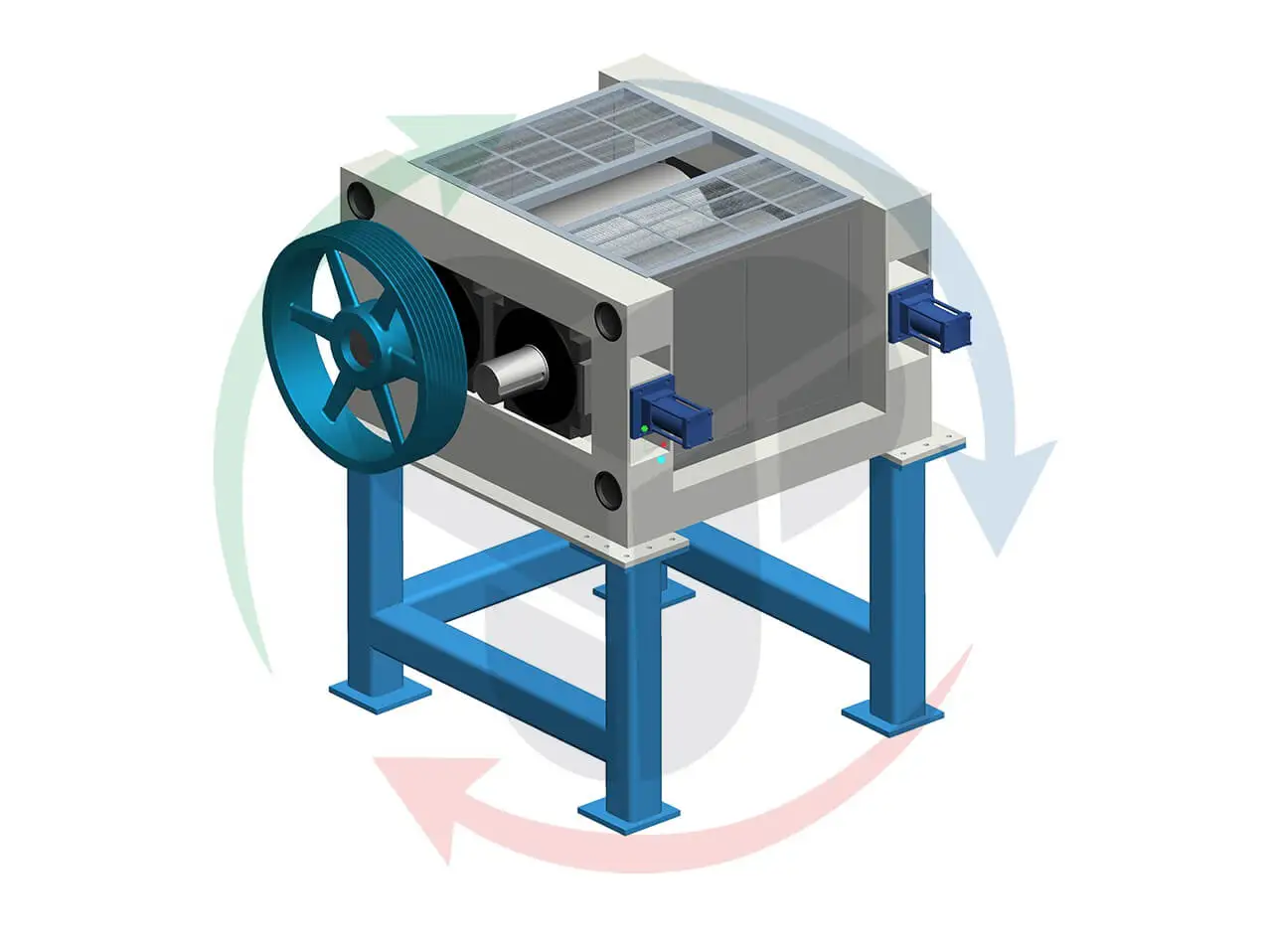

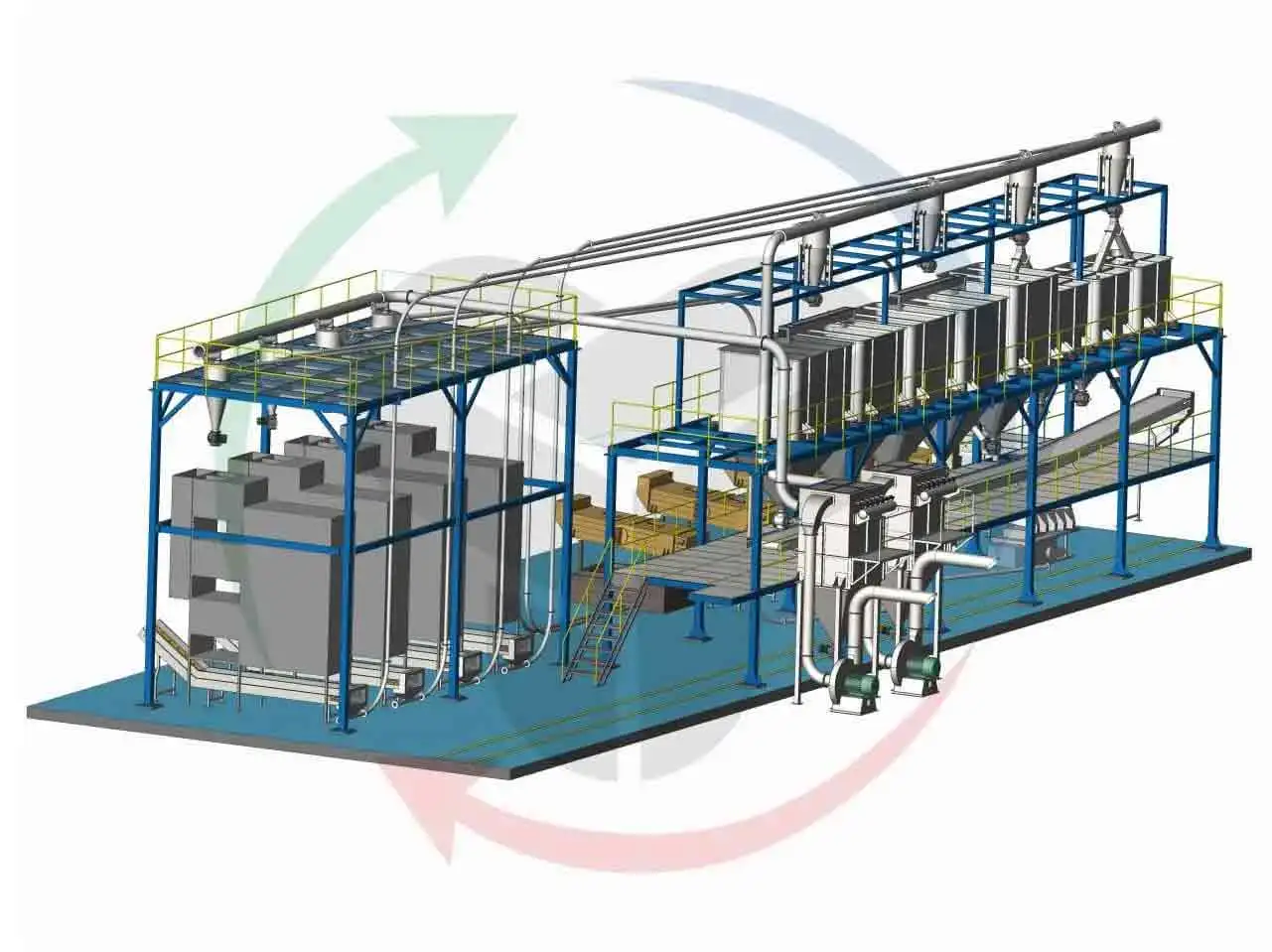

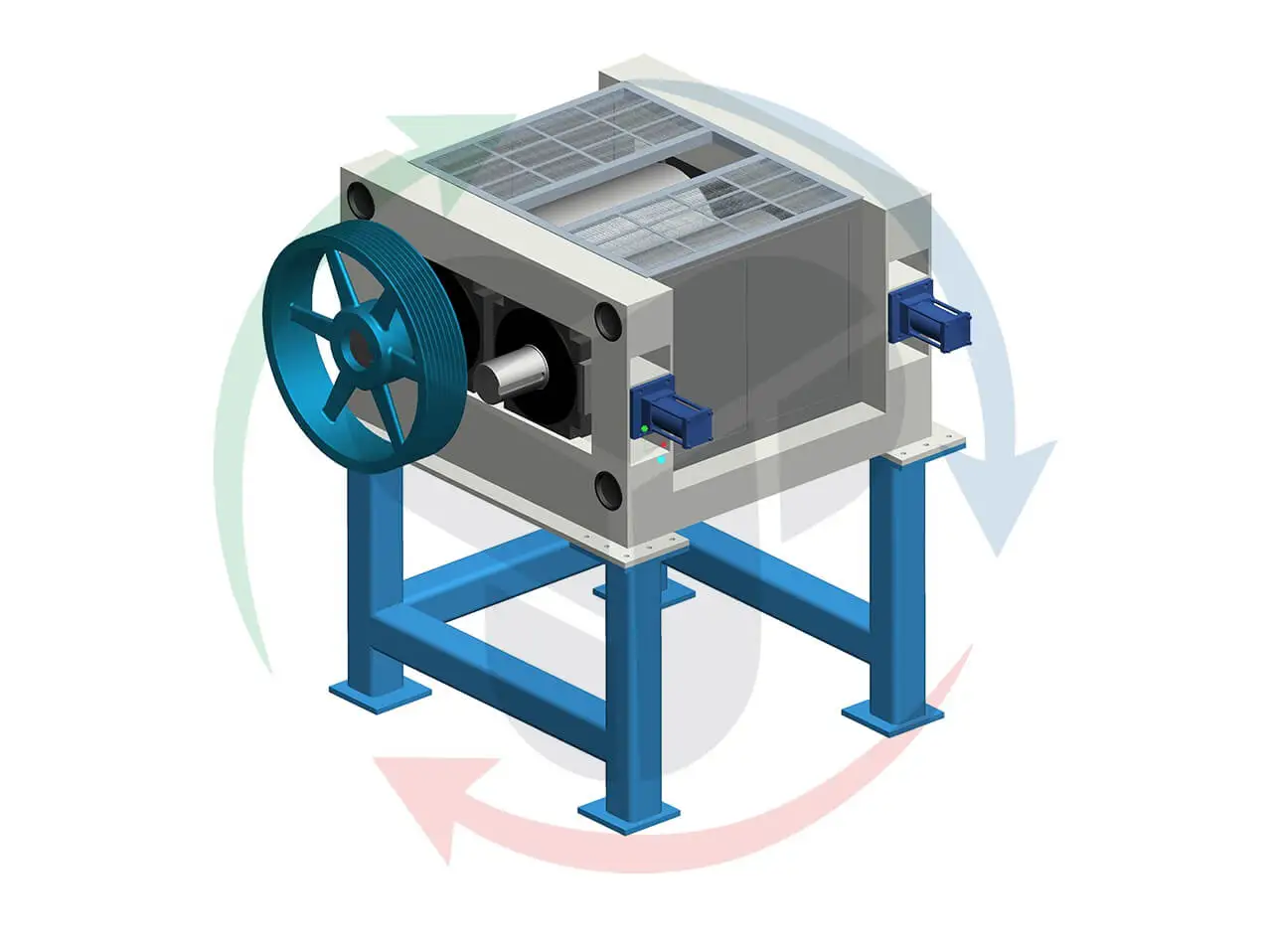

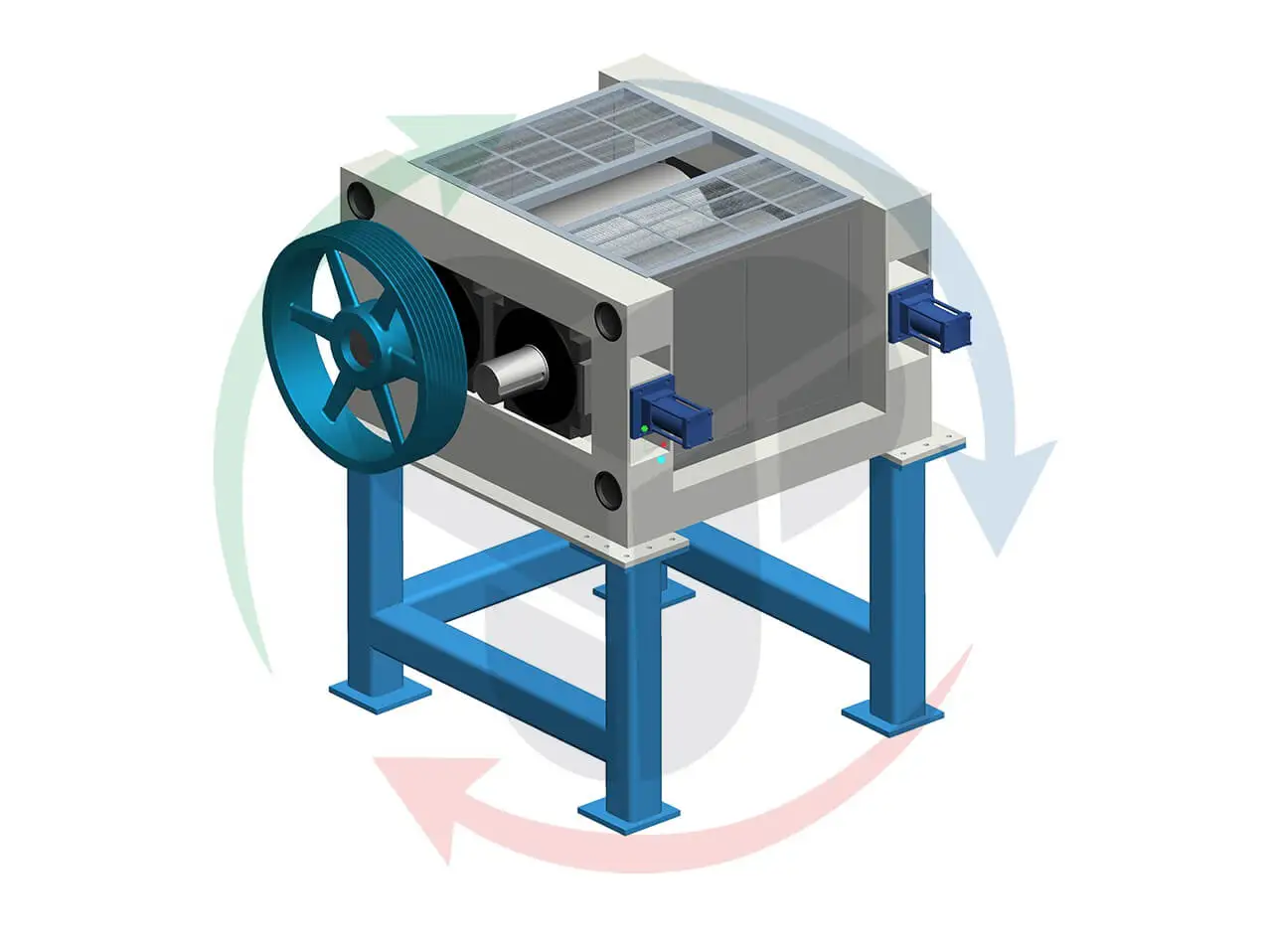

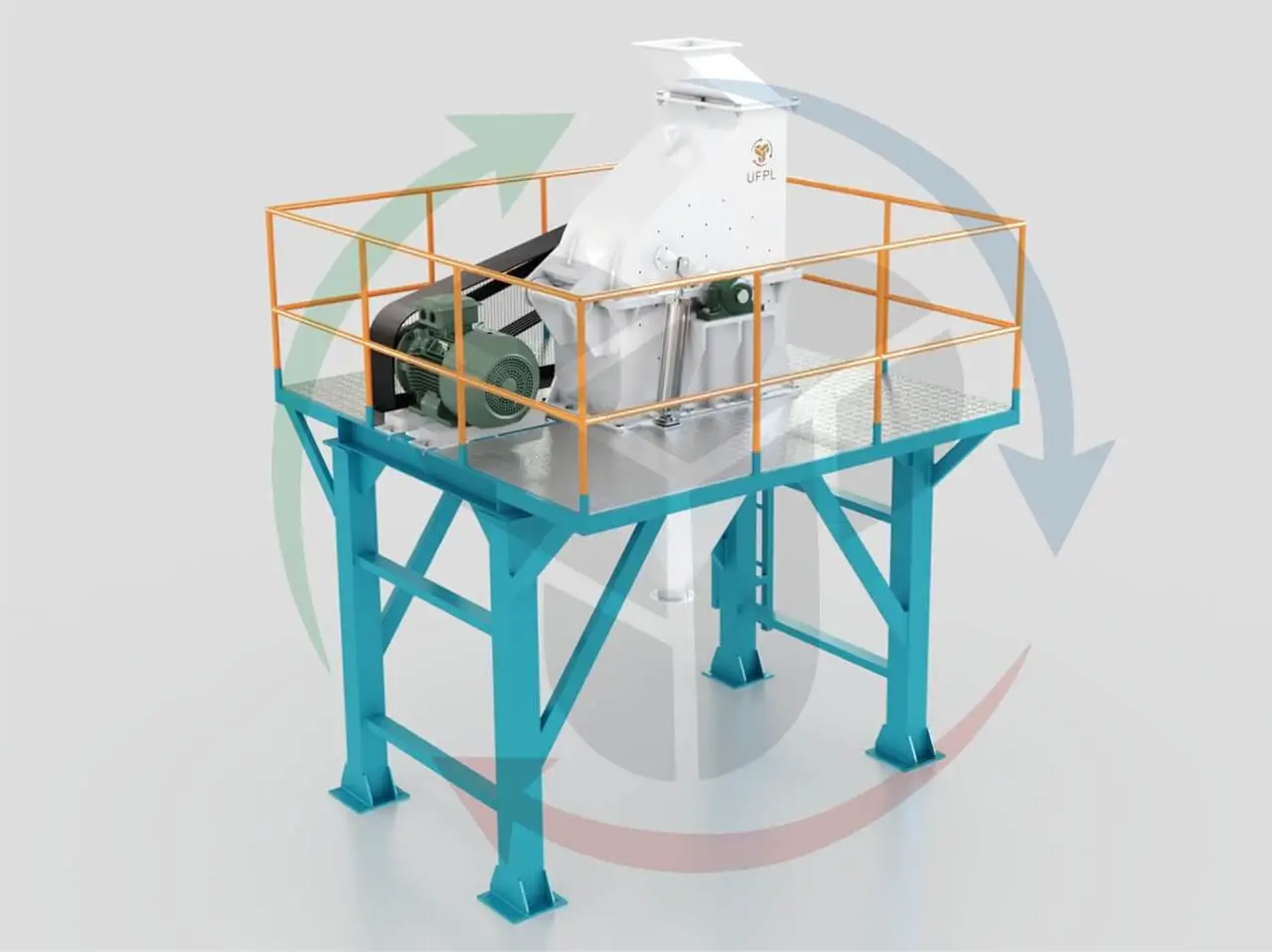

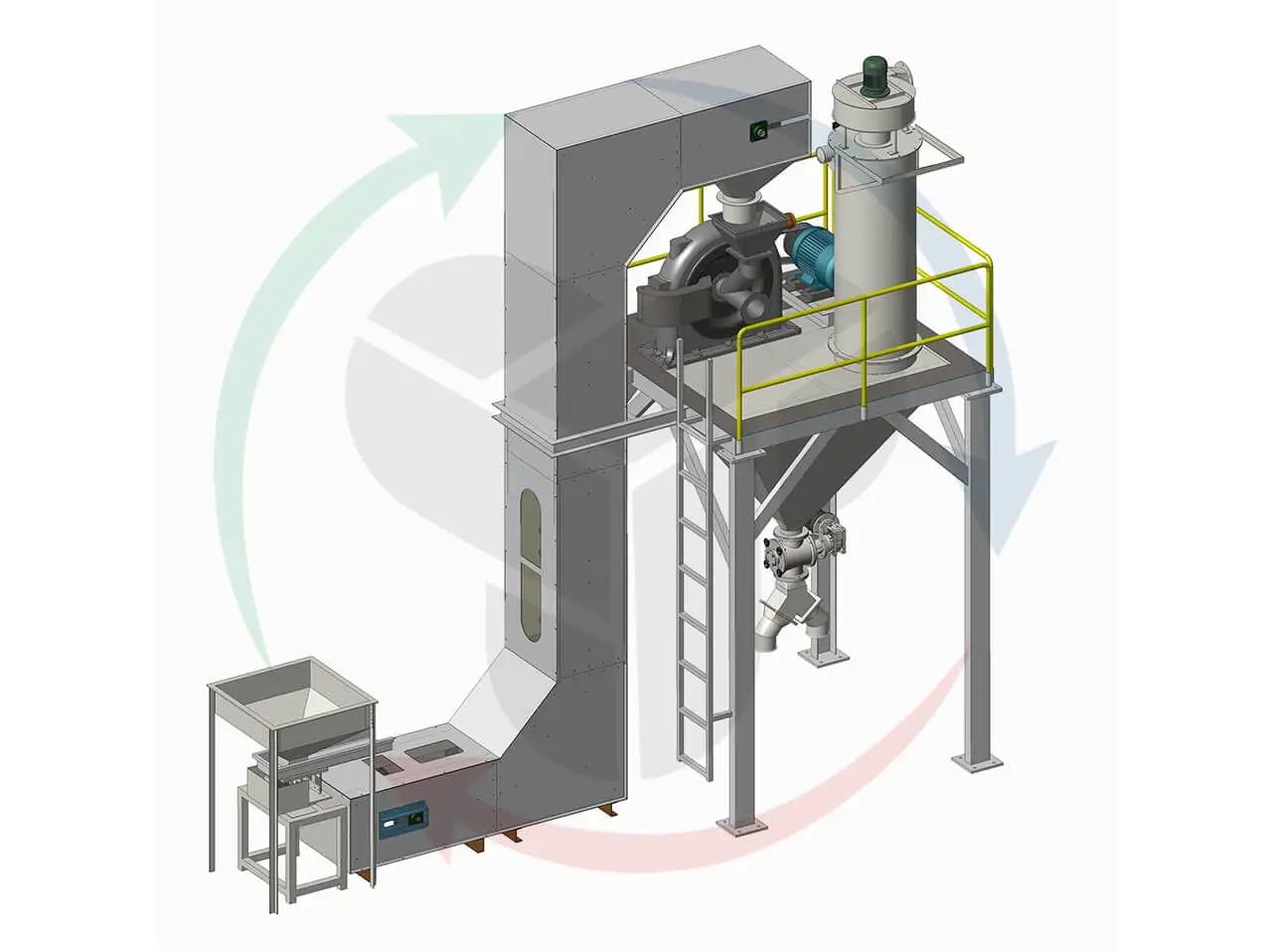

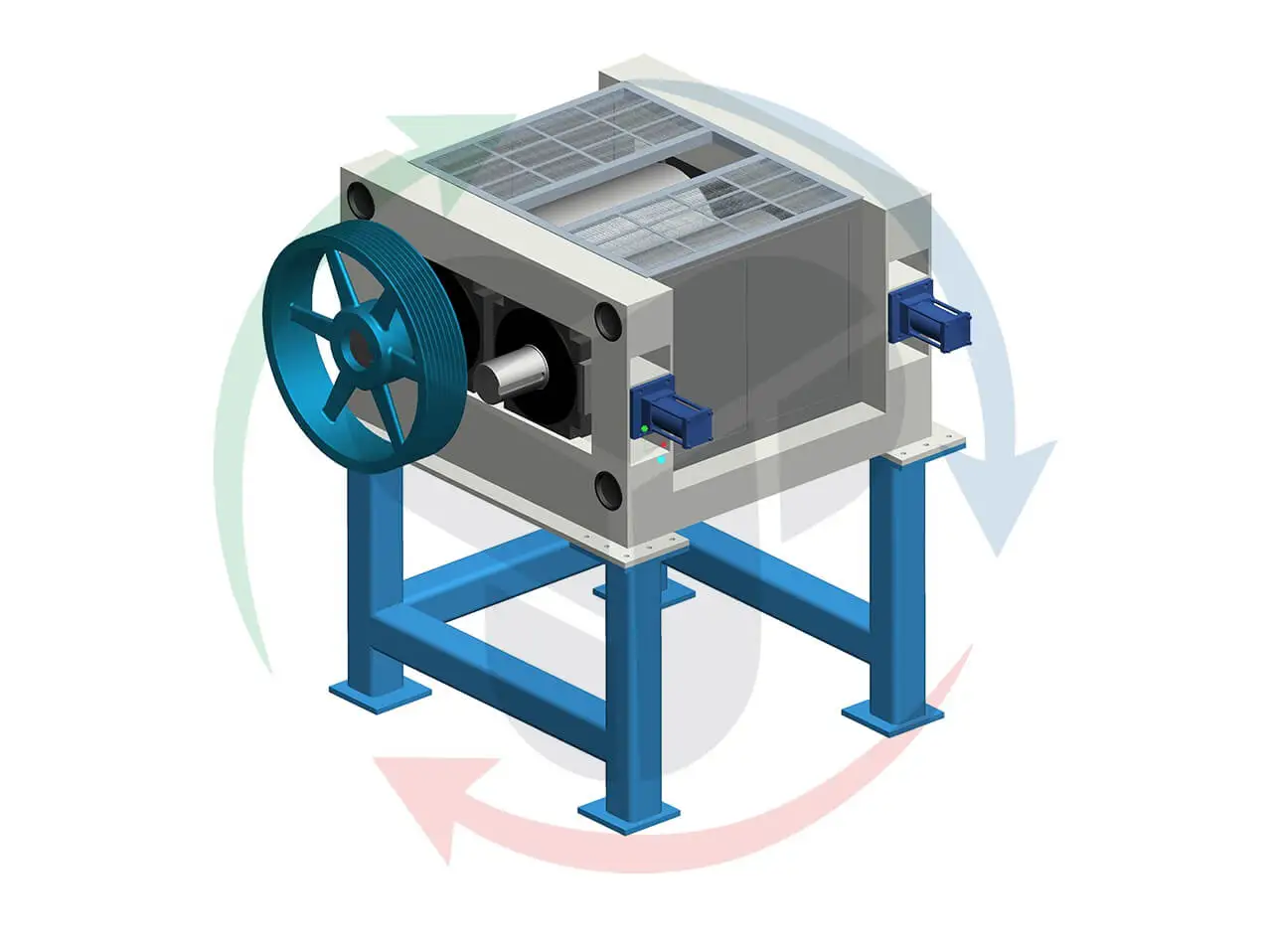

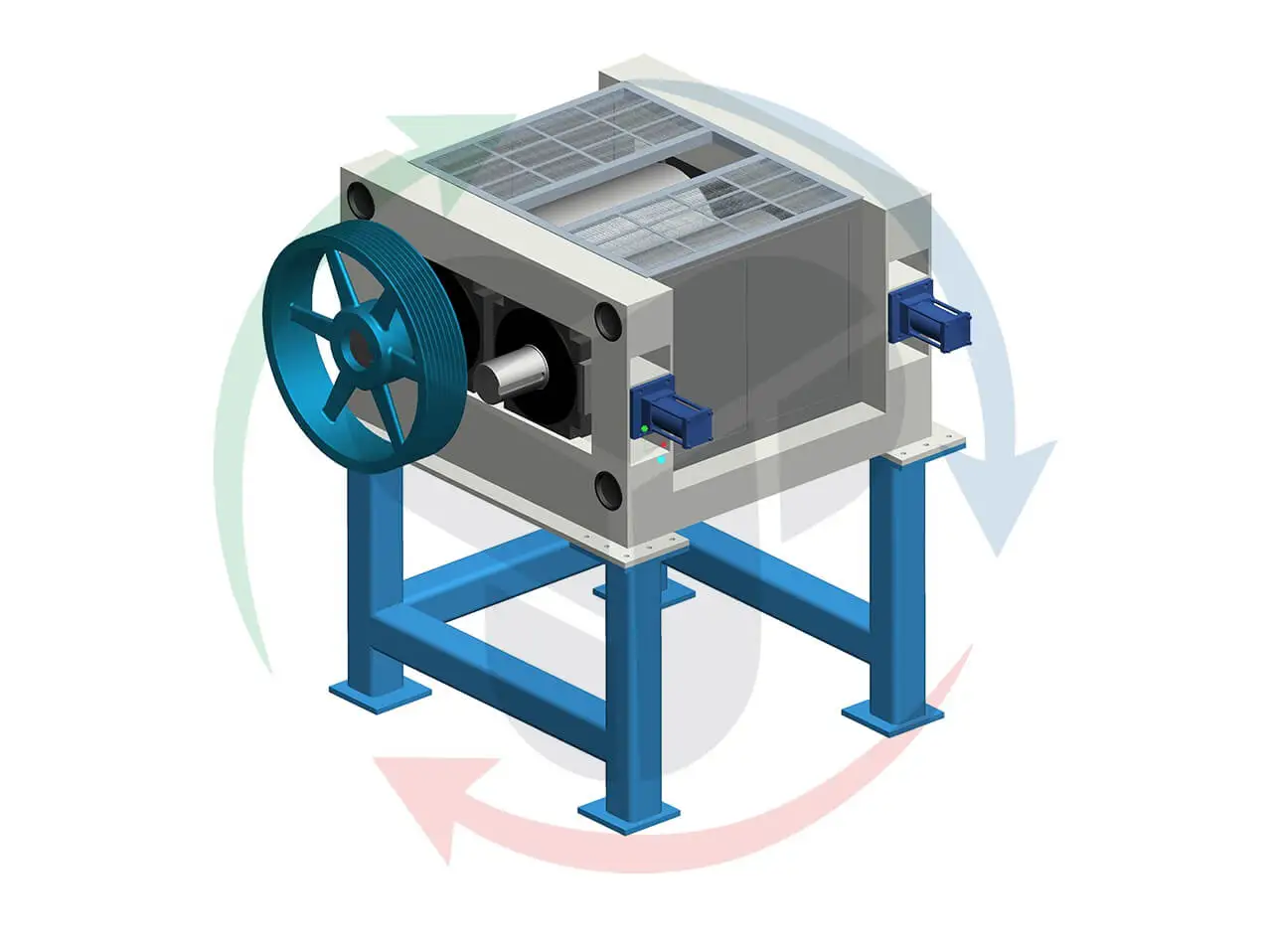

Size Reduction Equipment

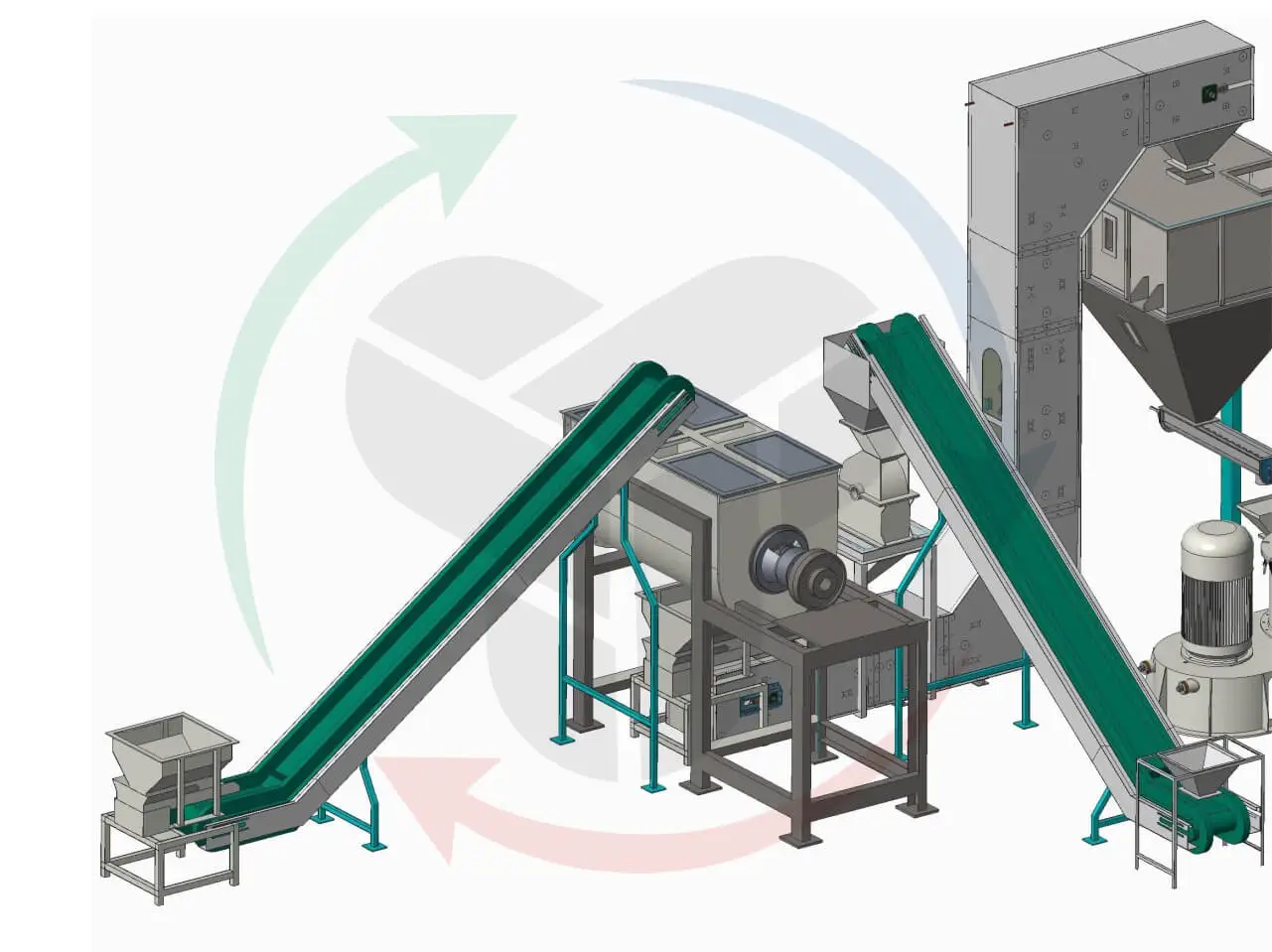

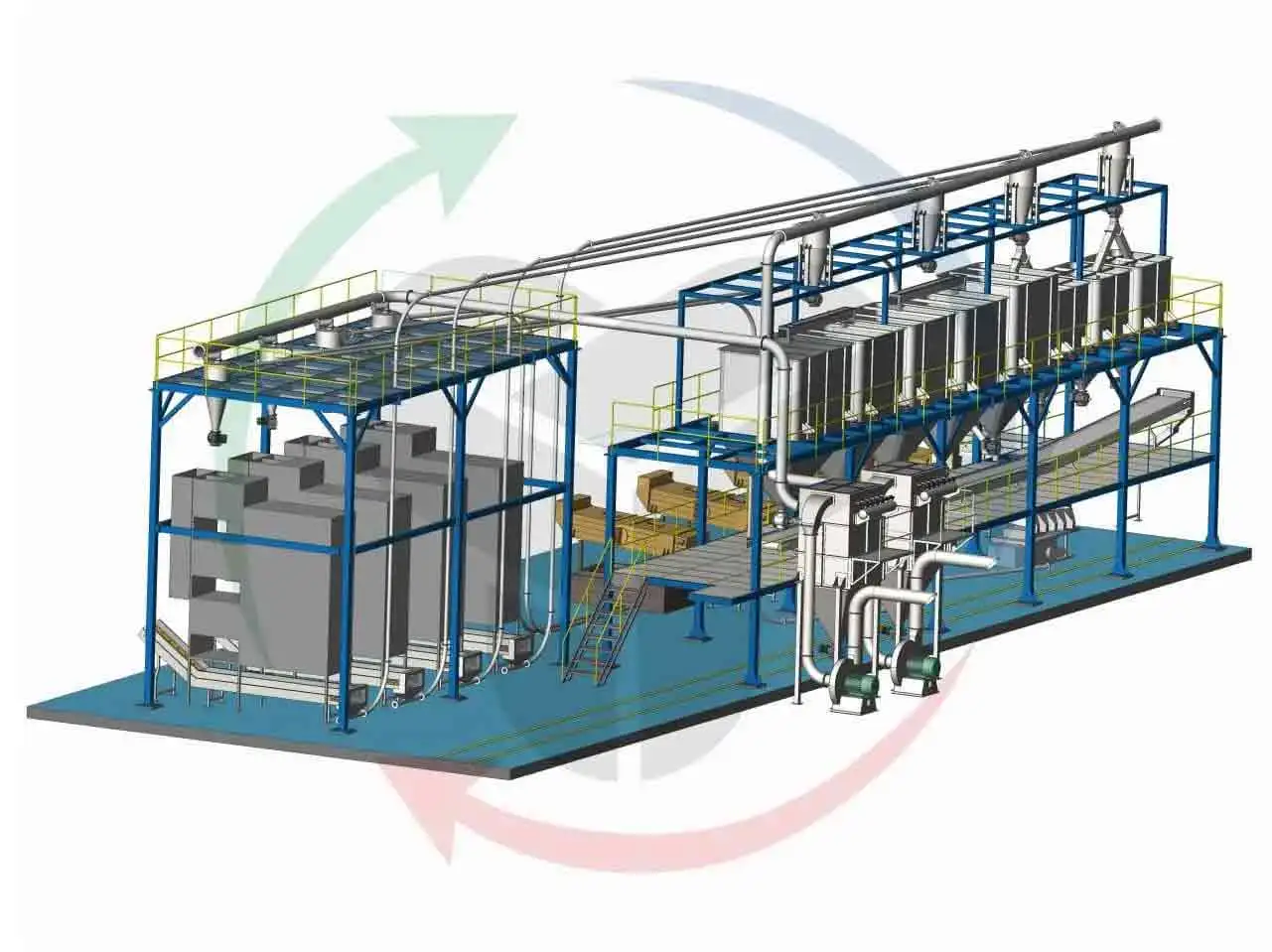

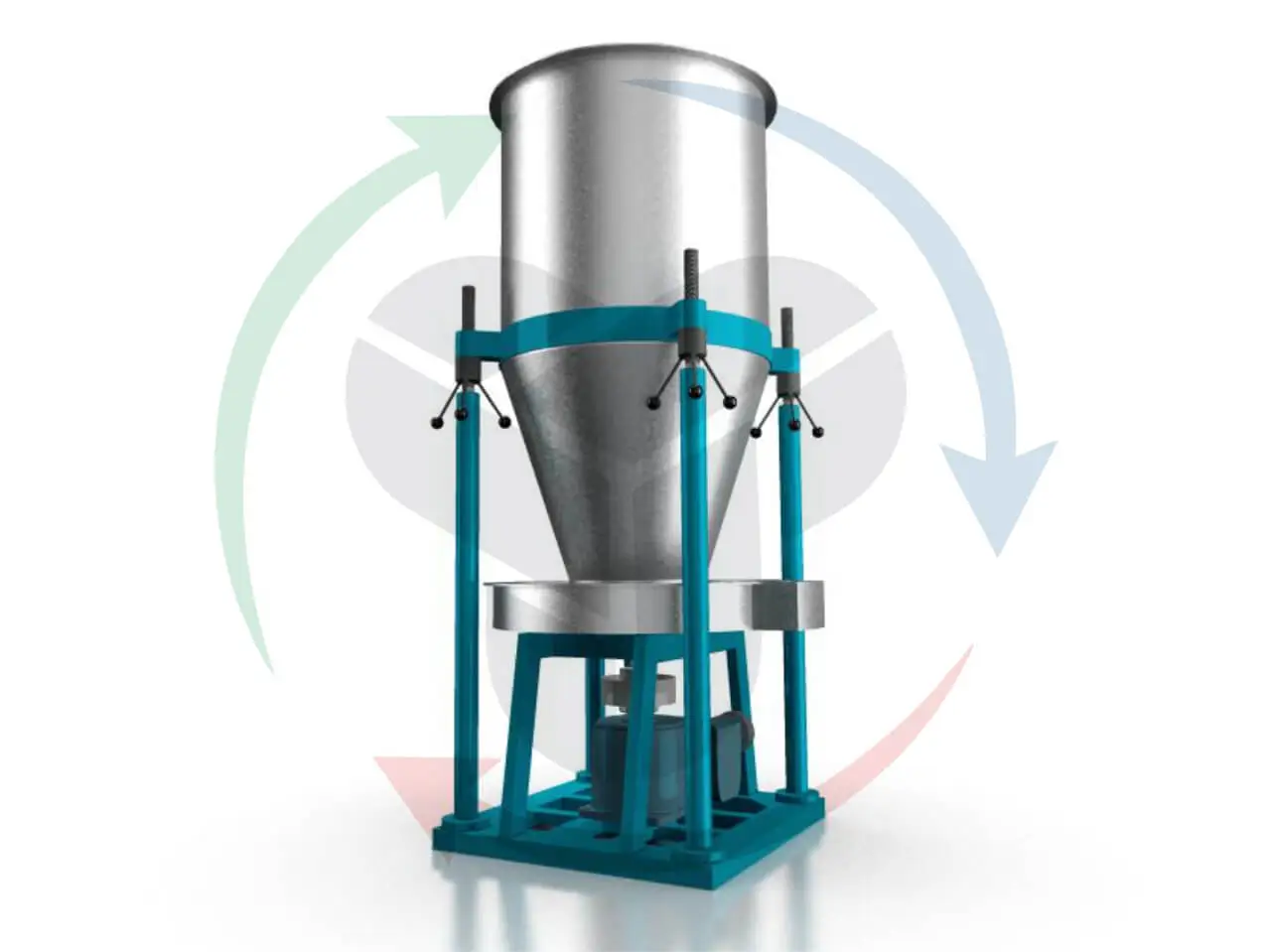

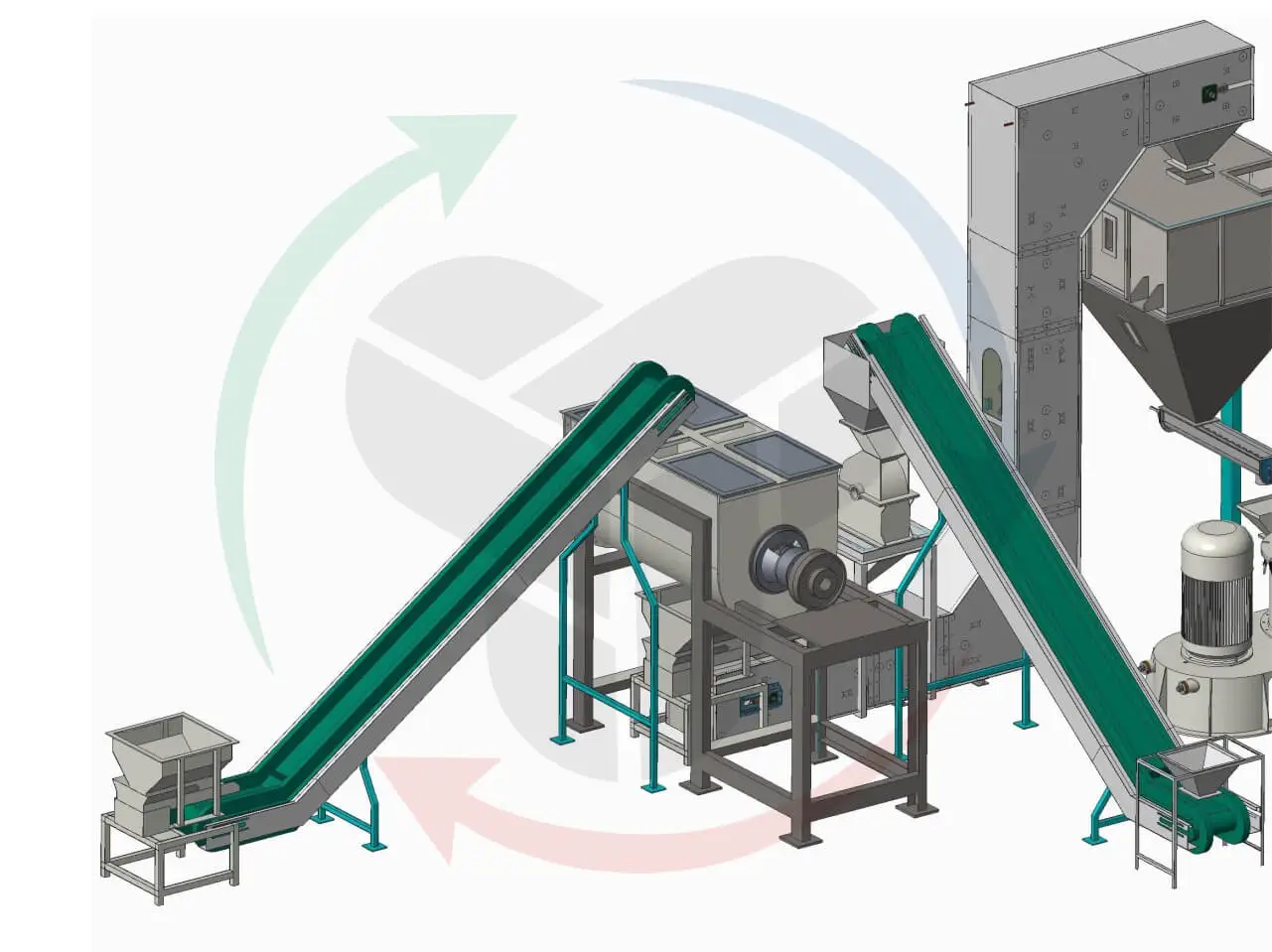

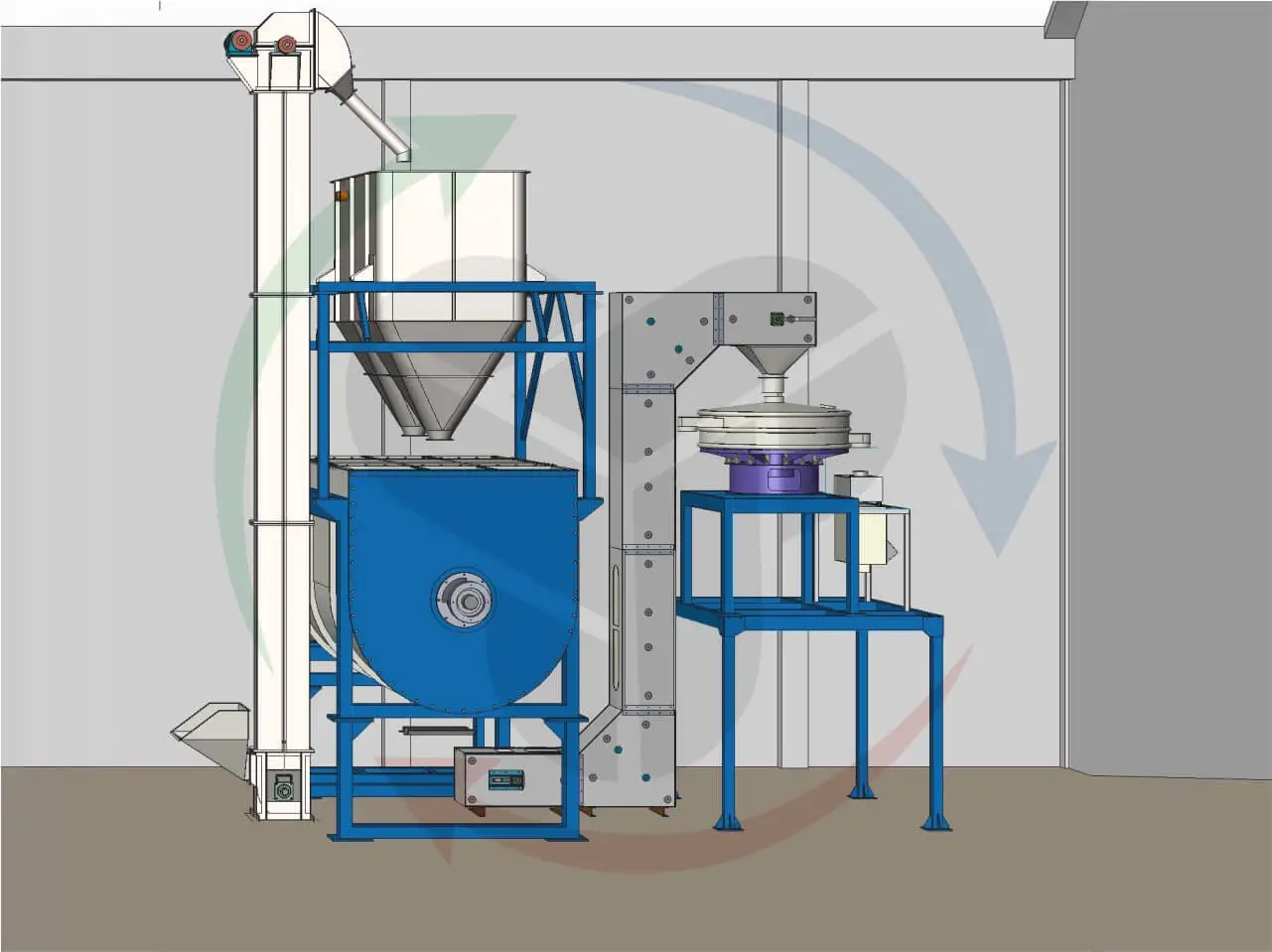

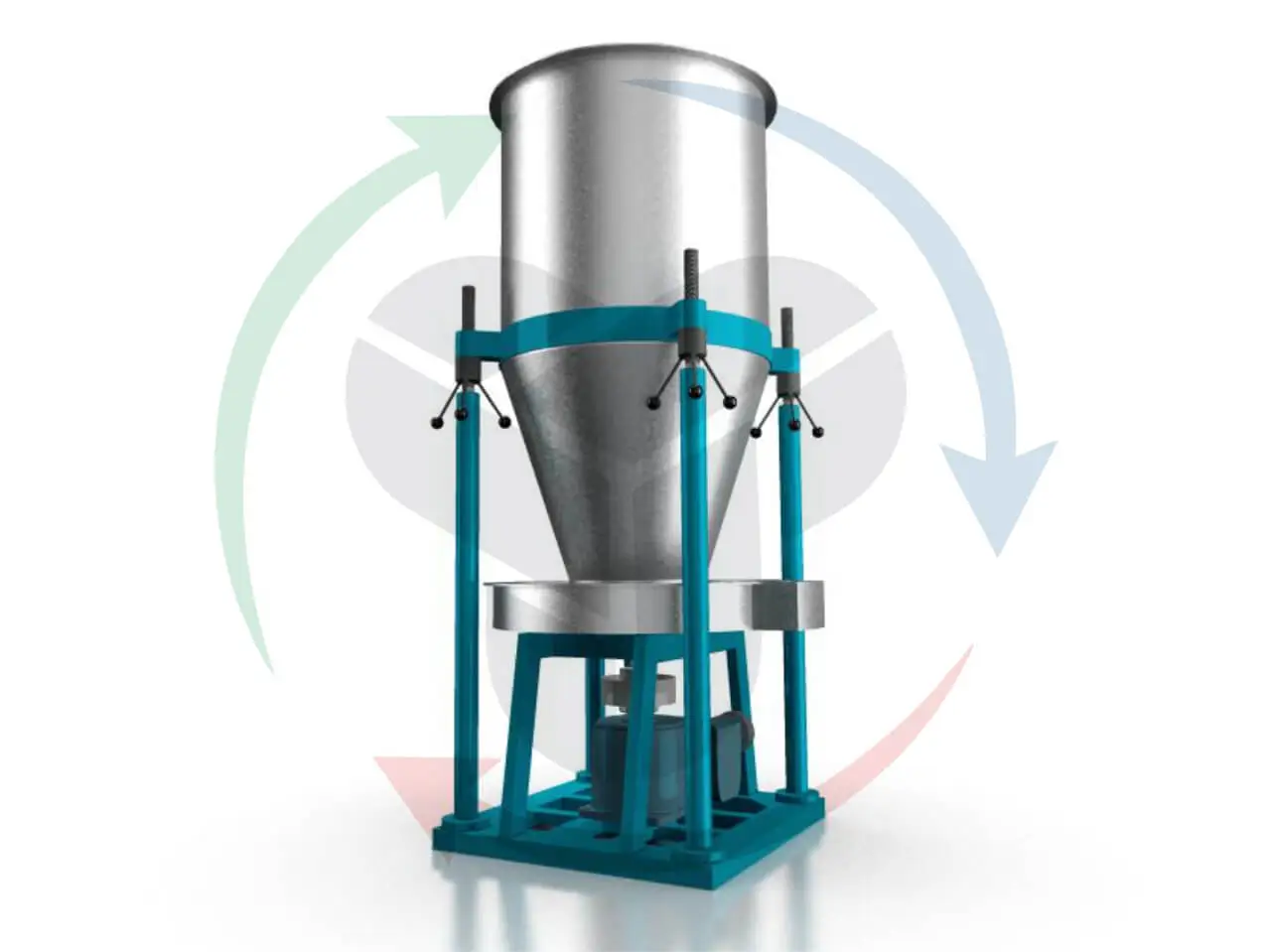

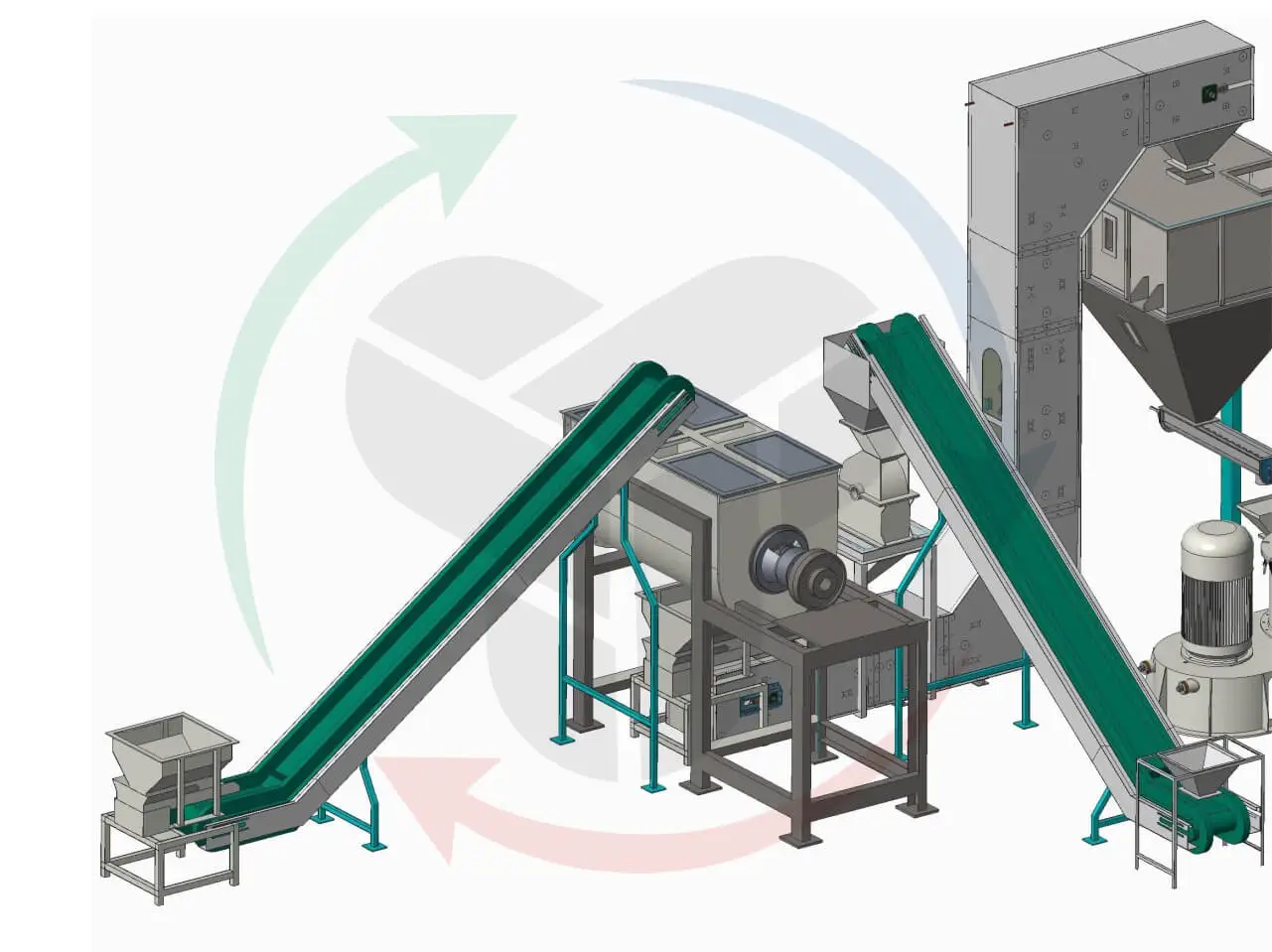

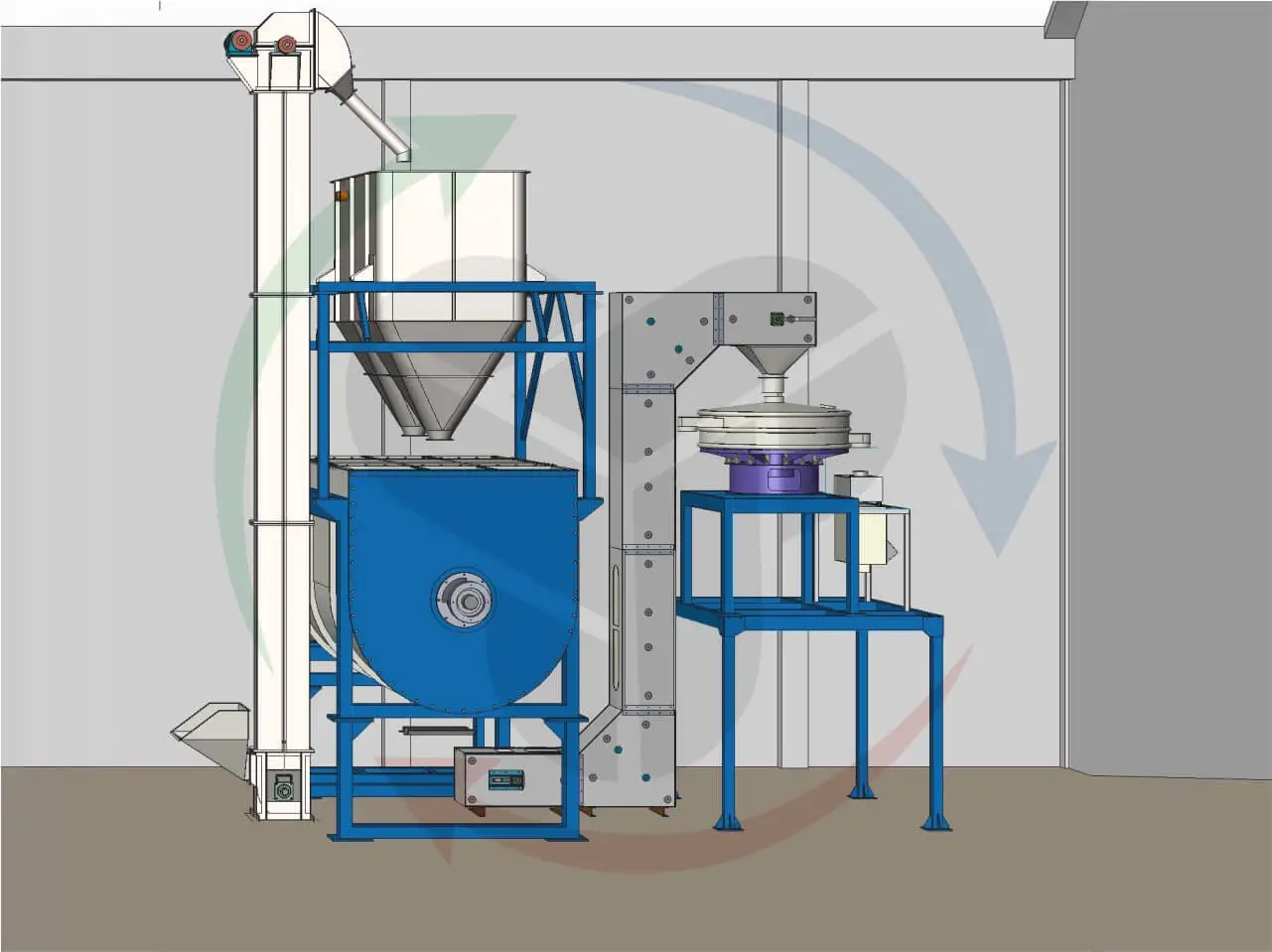

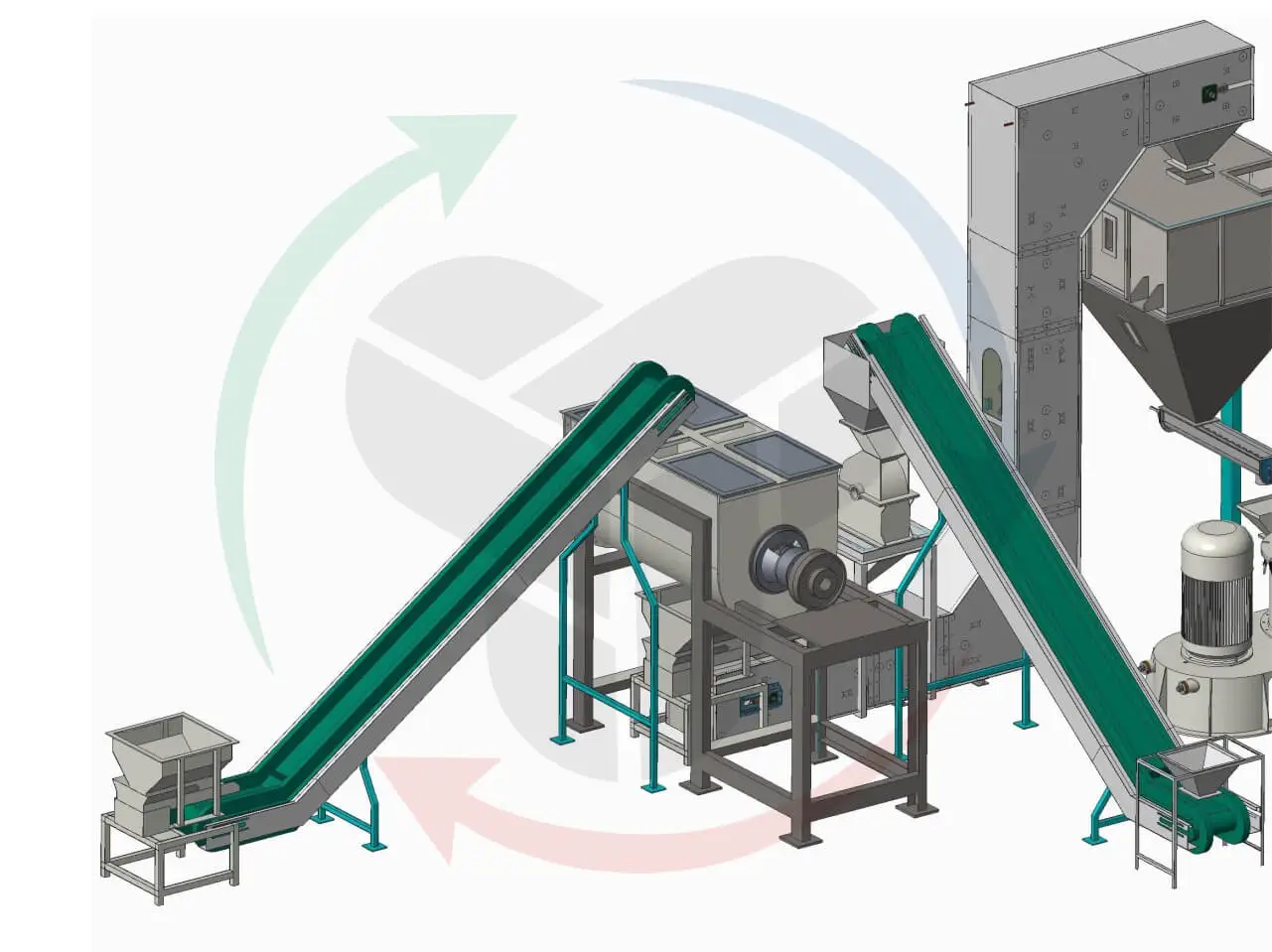

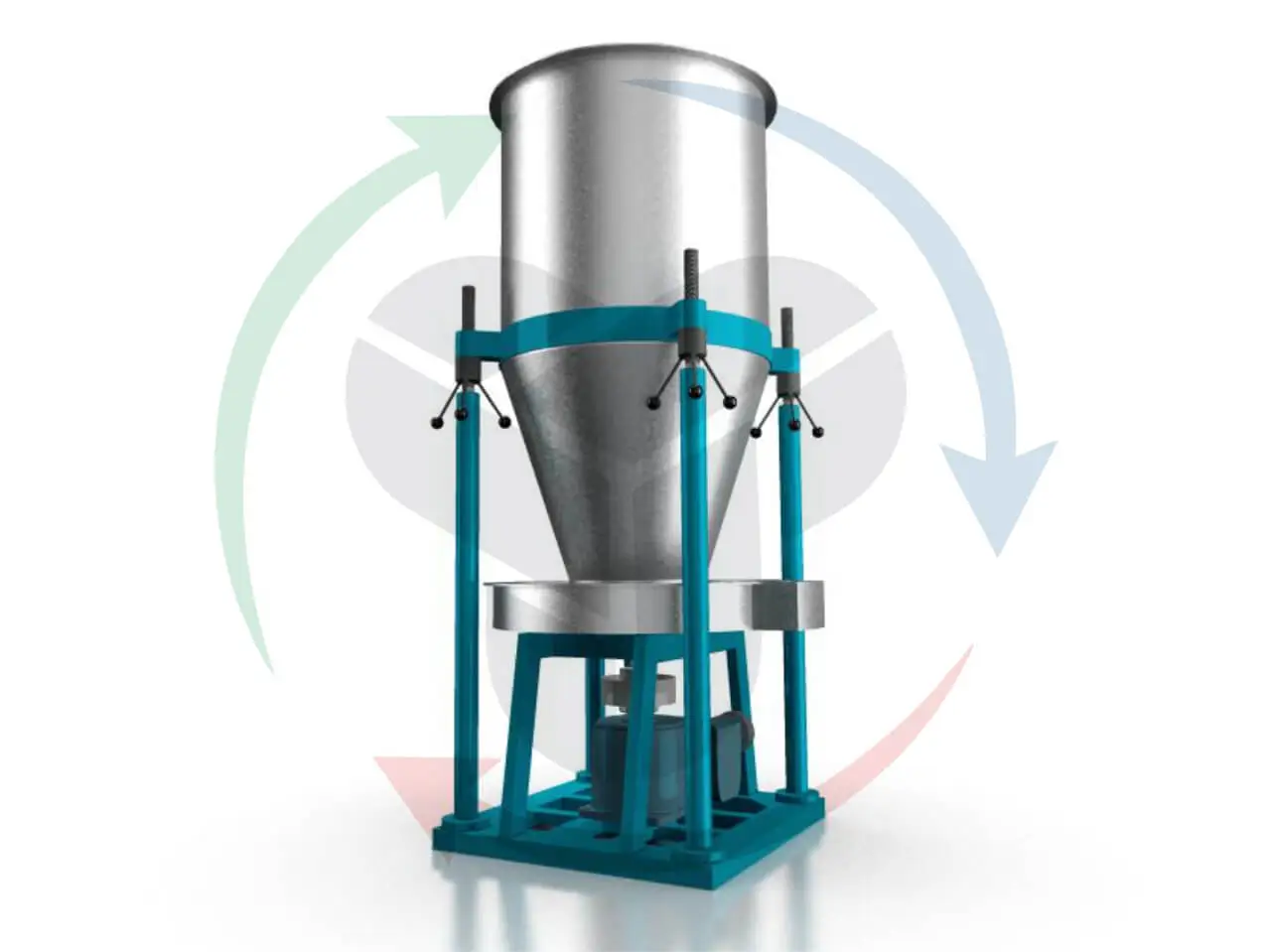

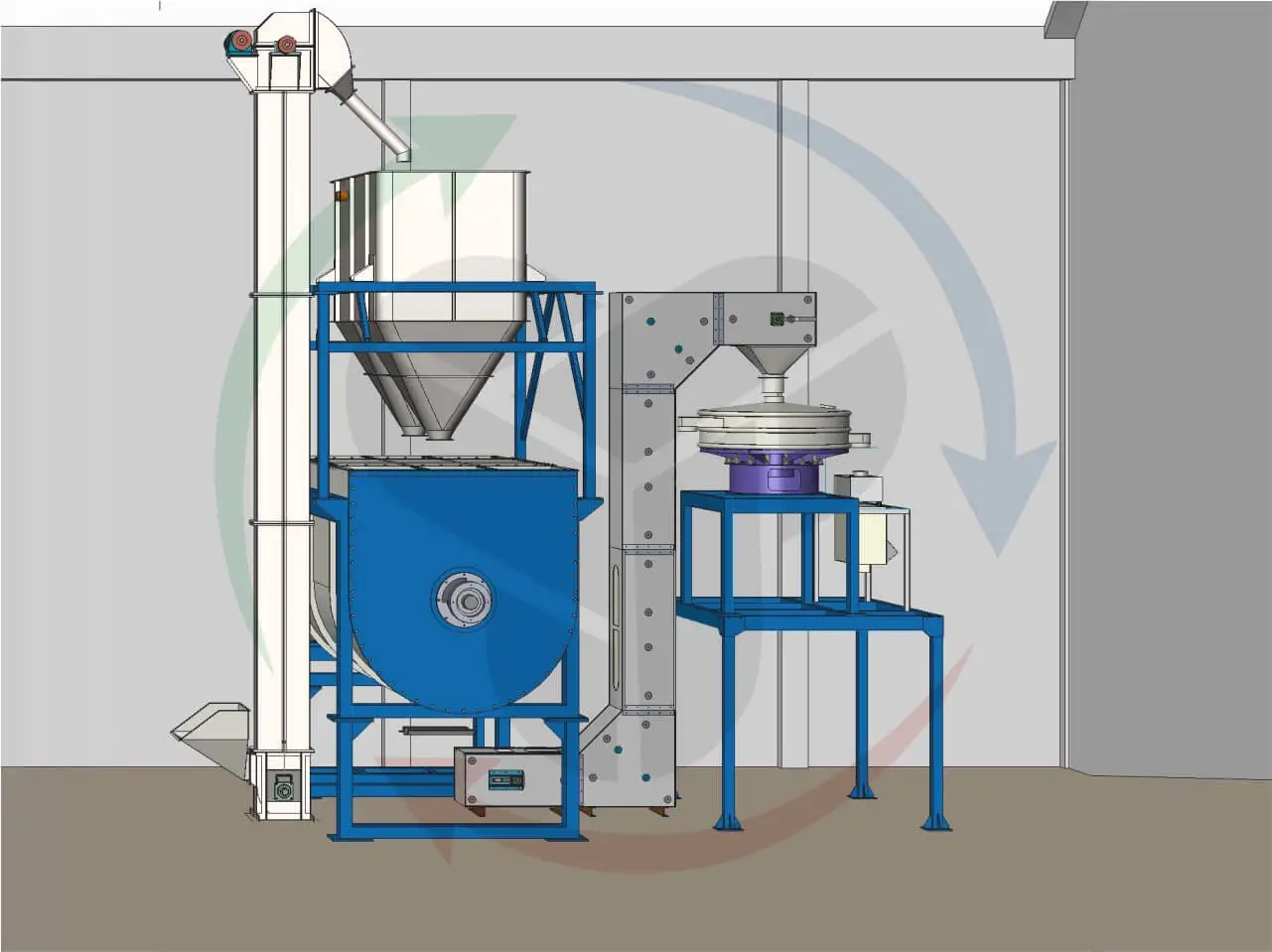

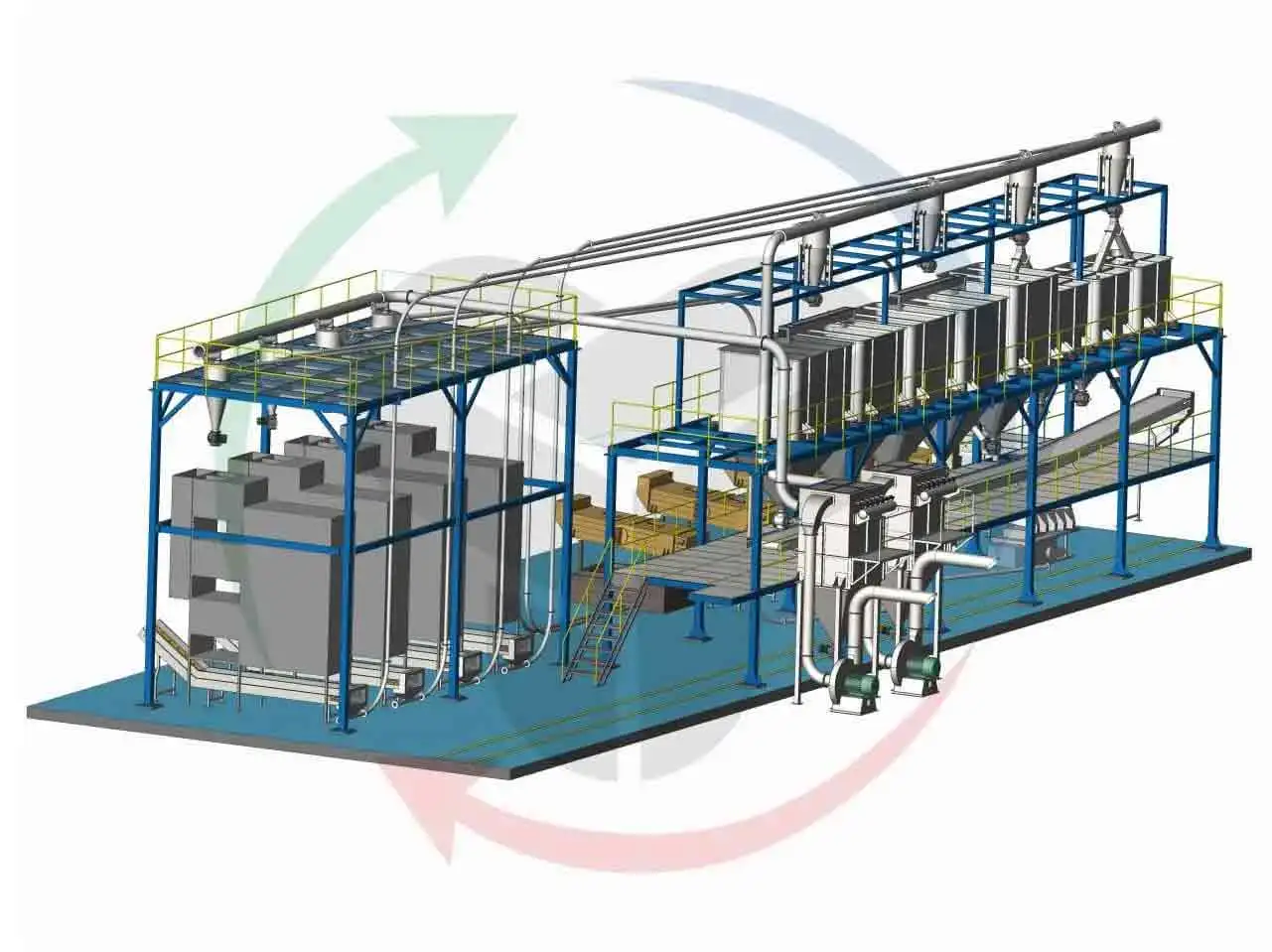

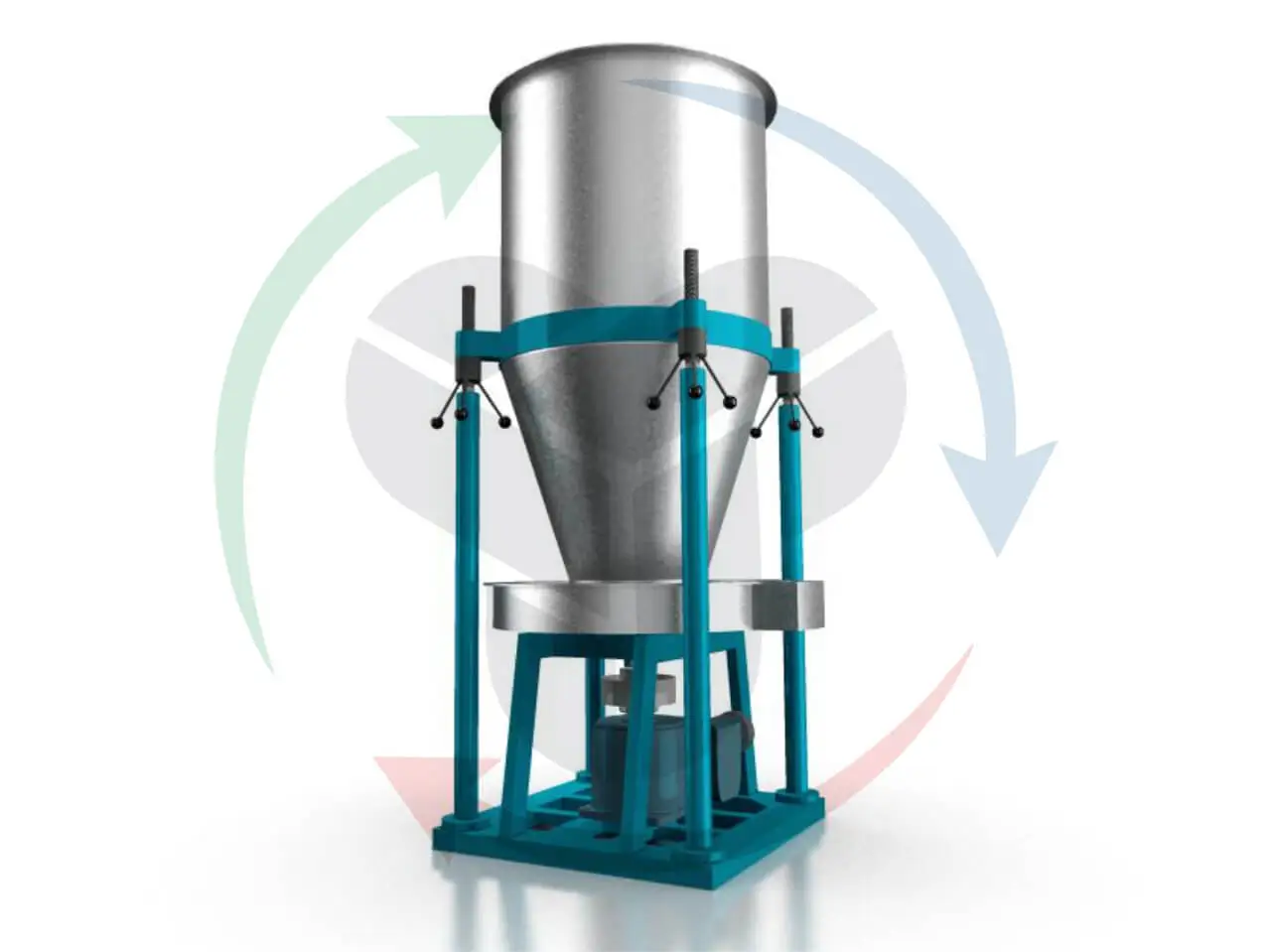

Material Handling Equipment

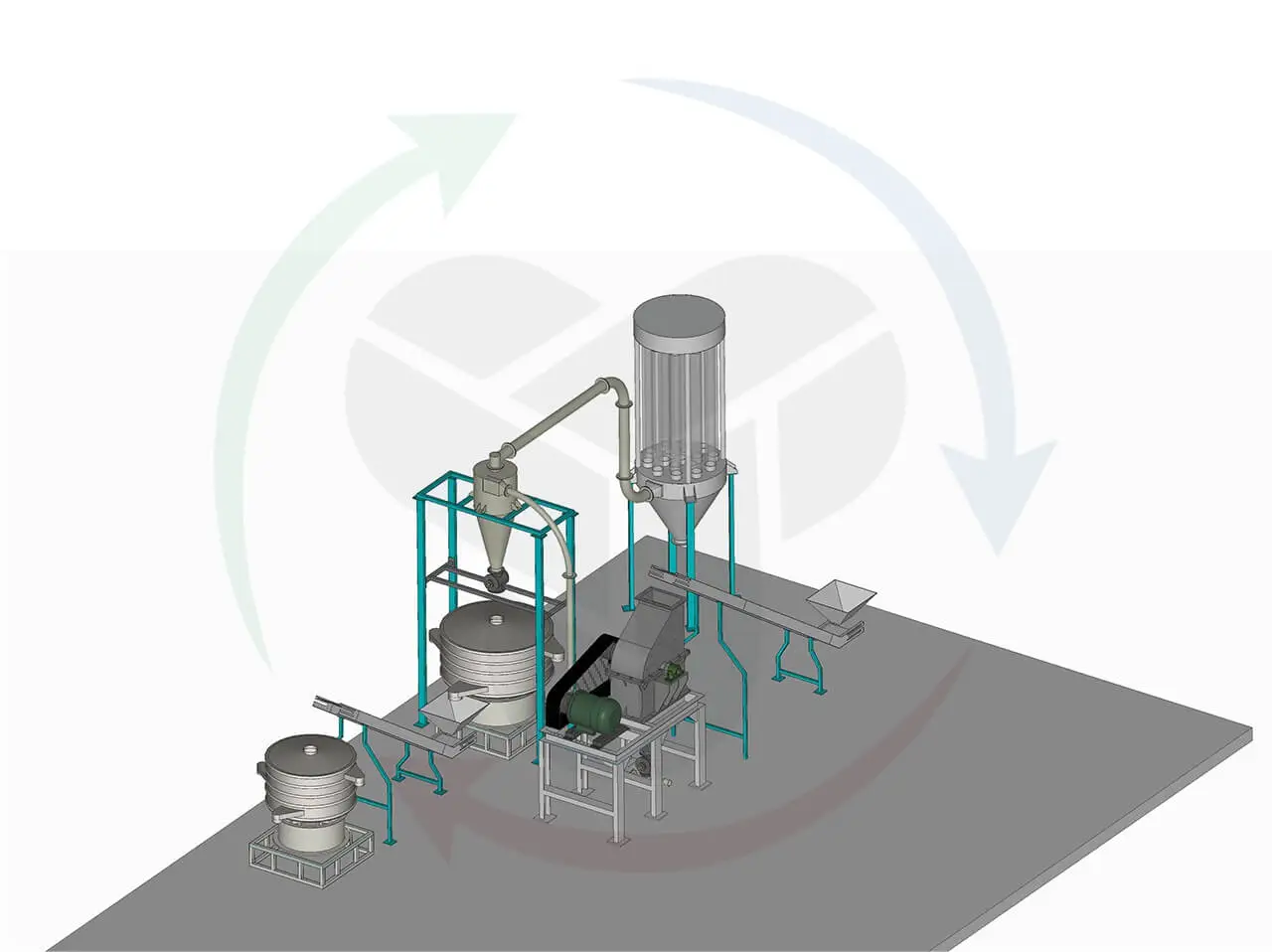

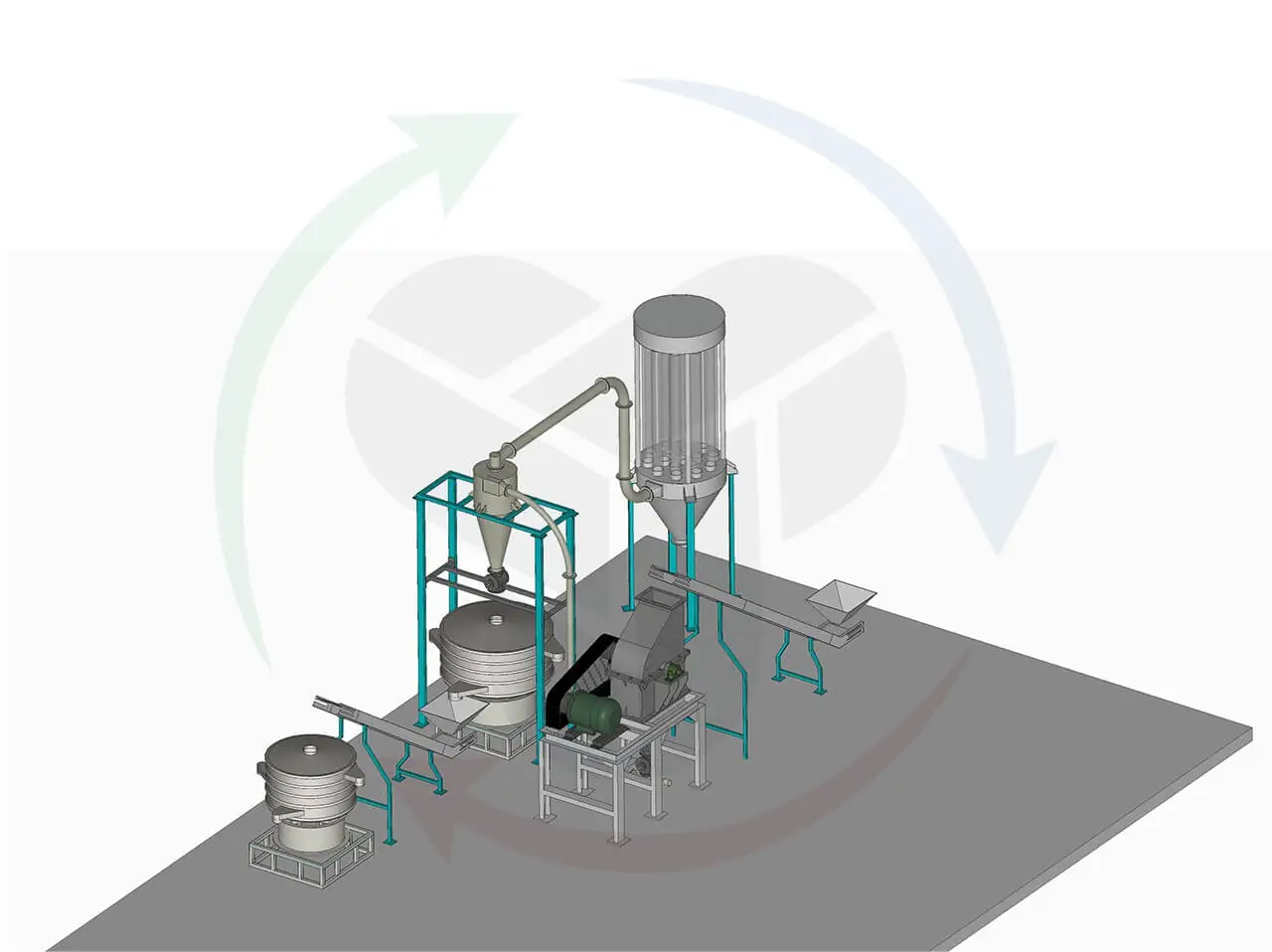

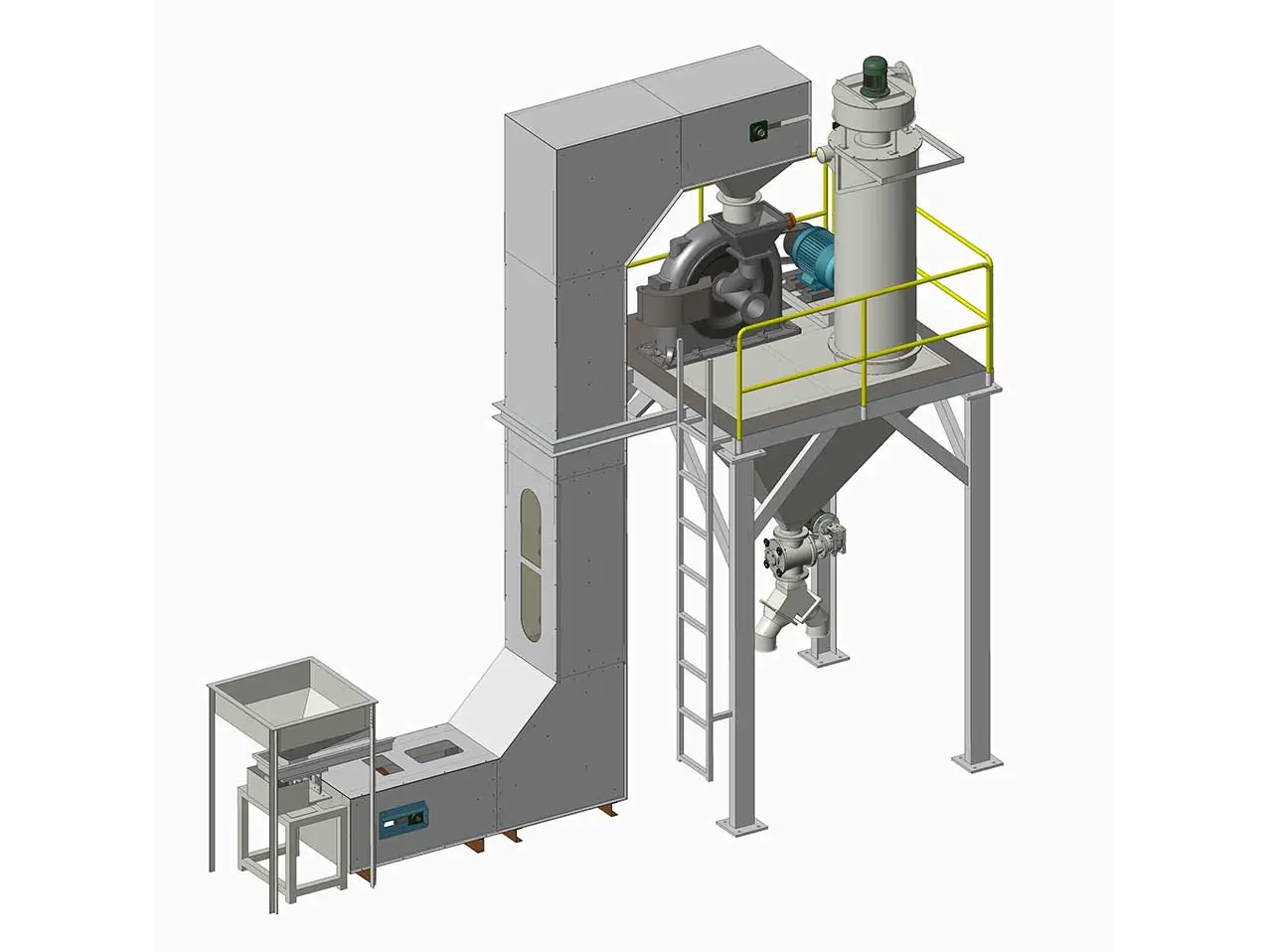

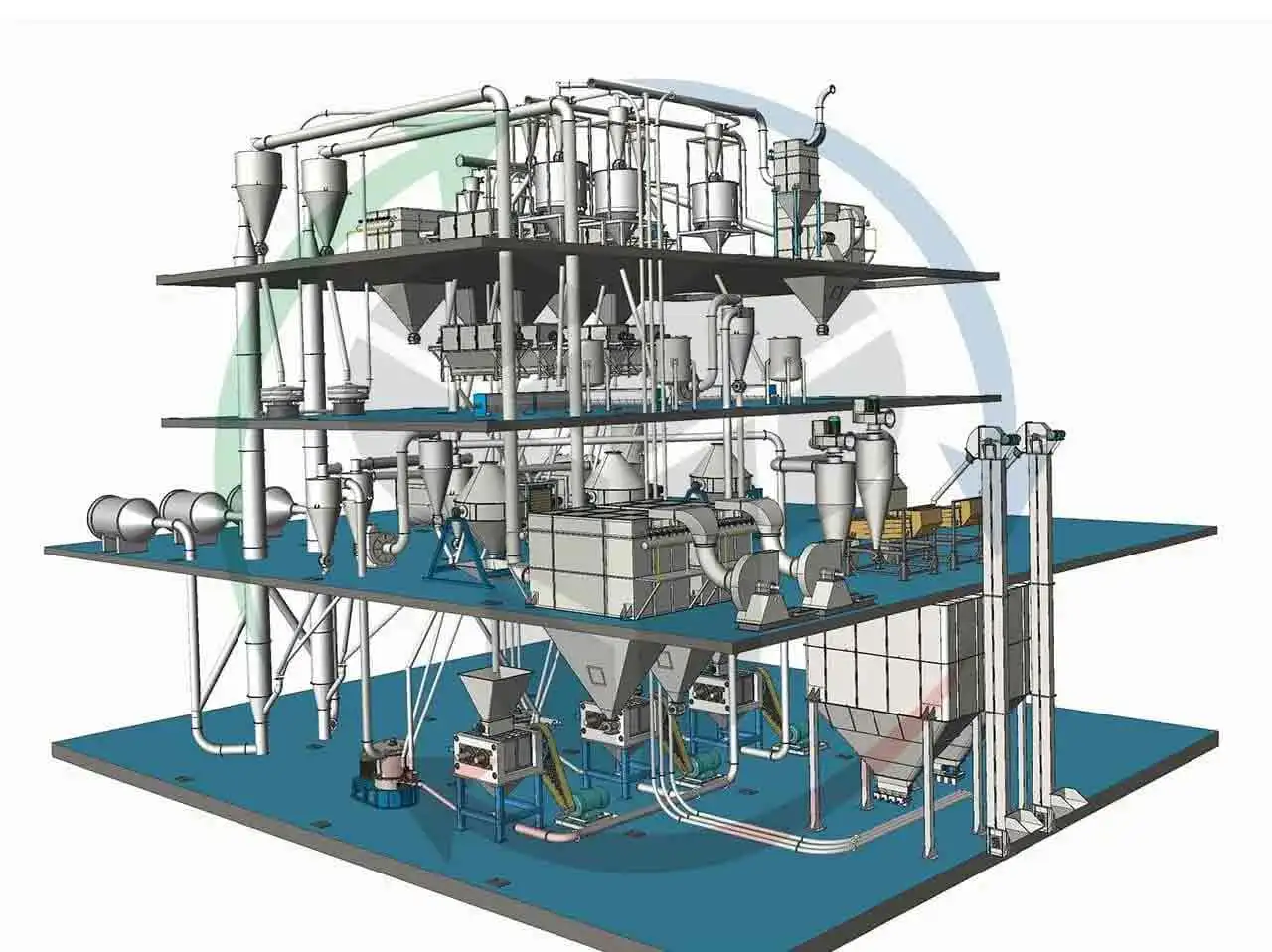

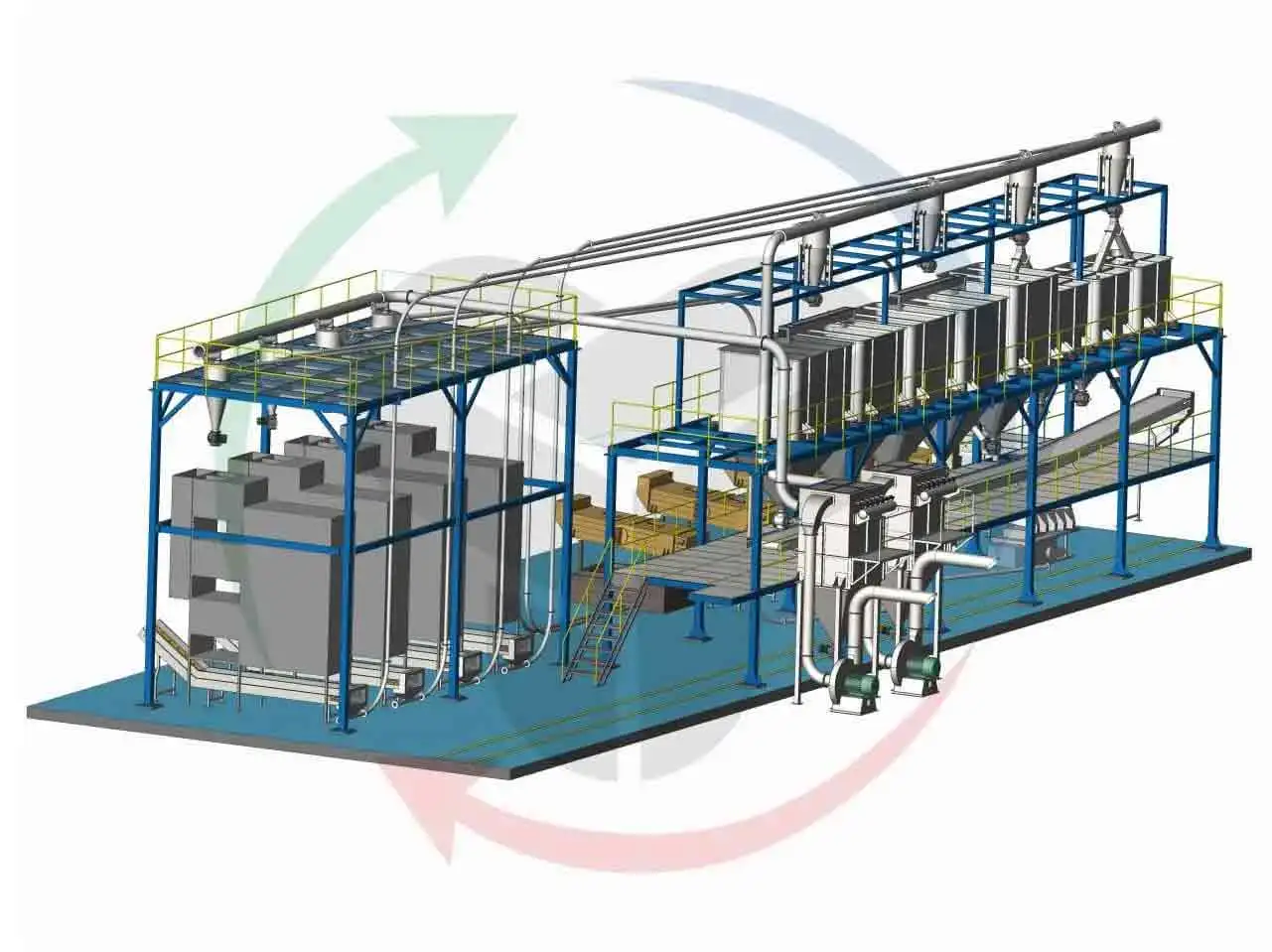

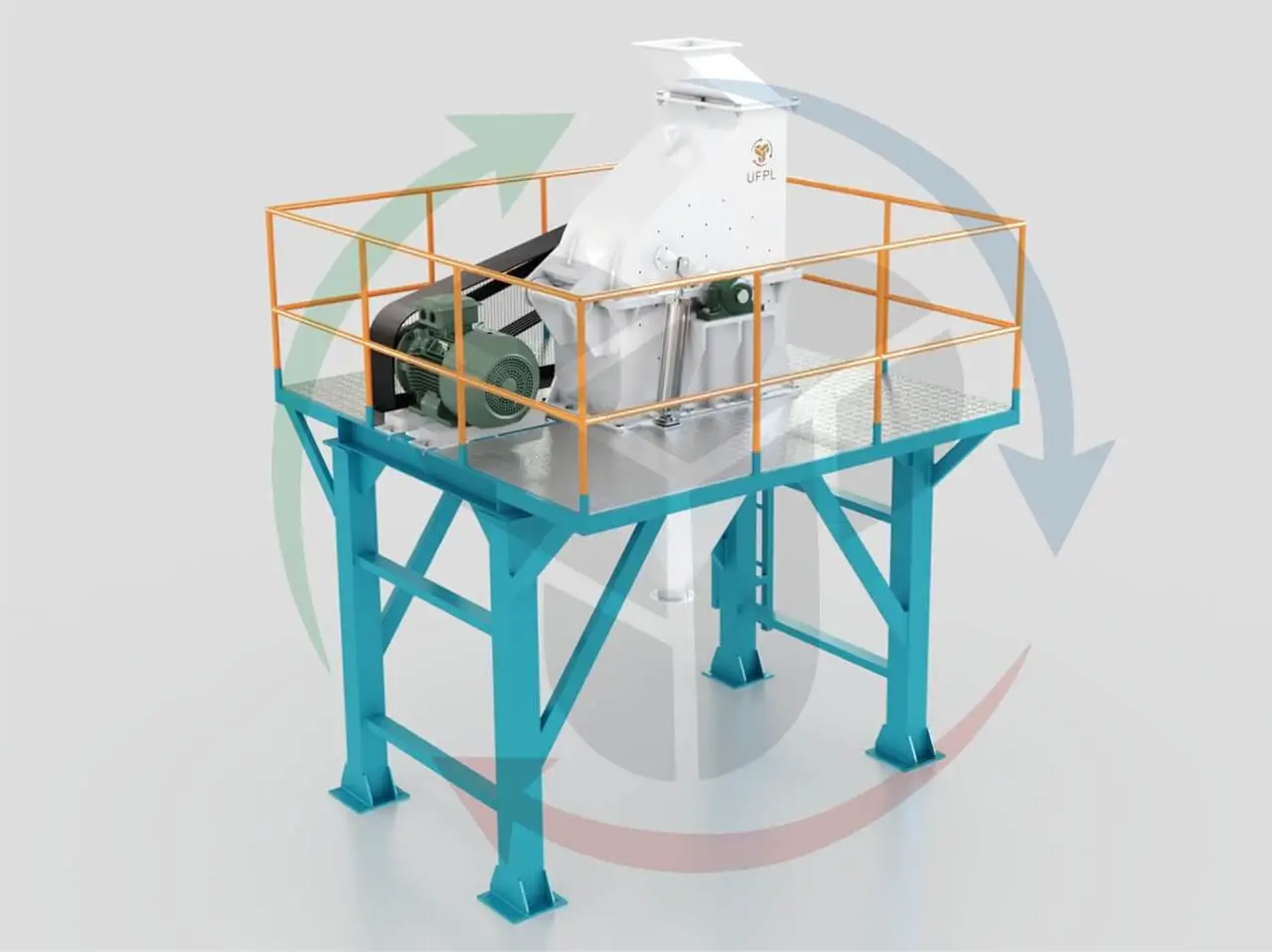

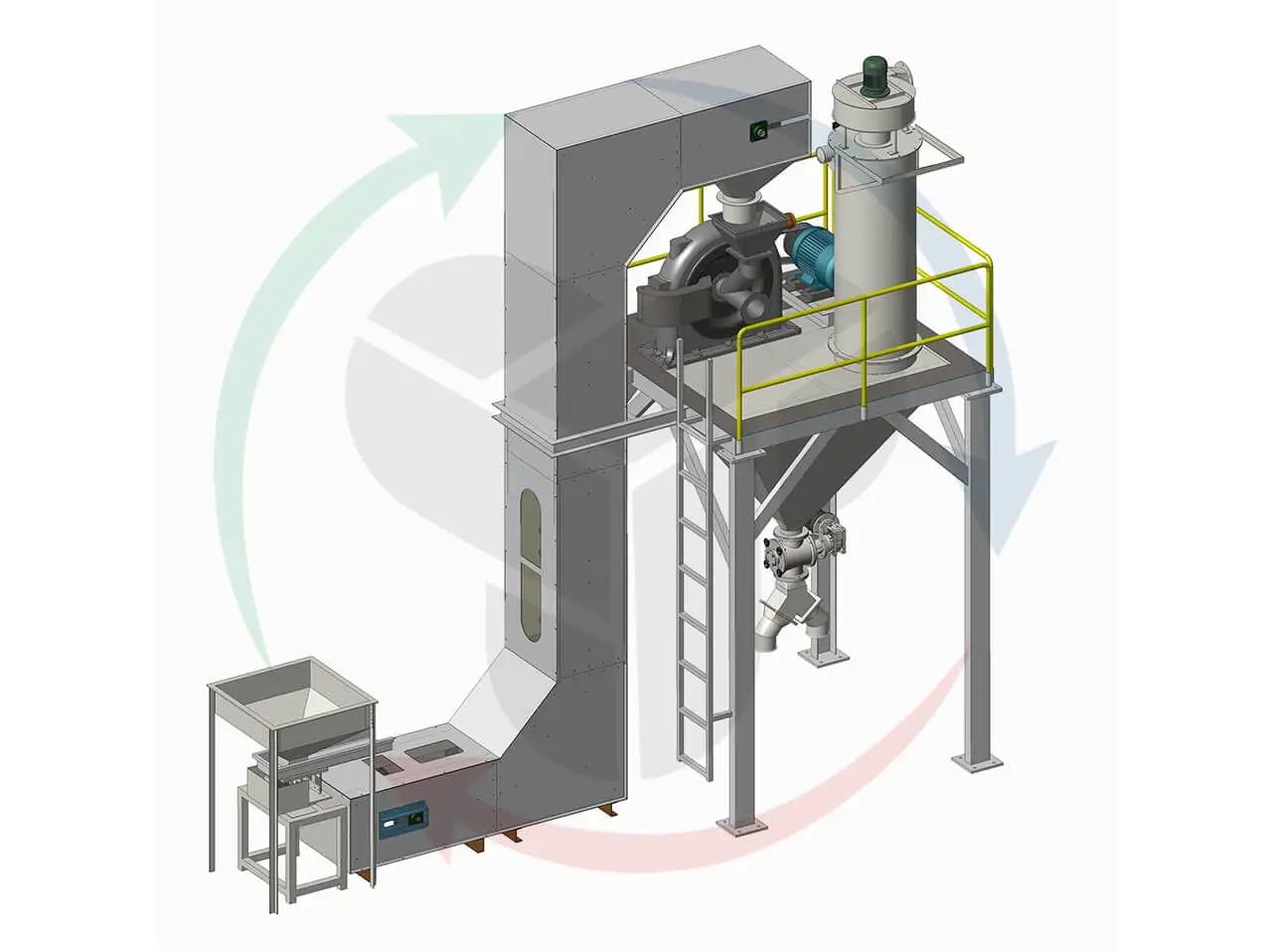

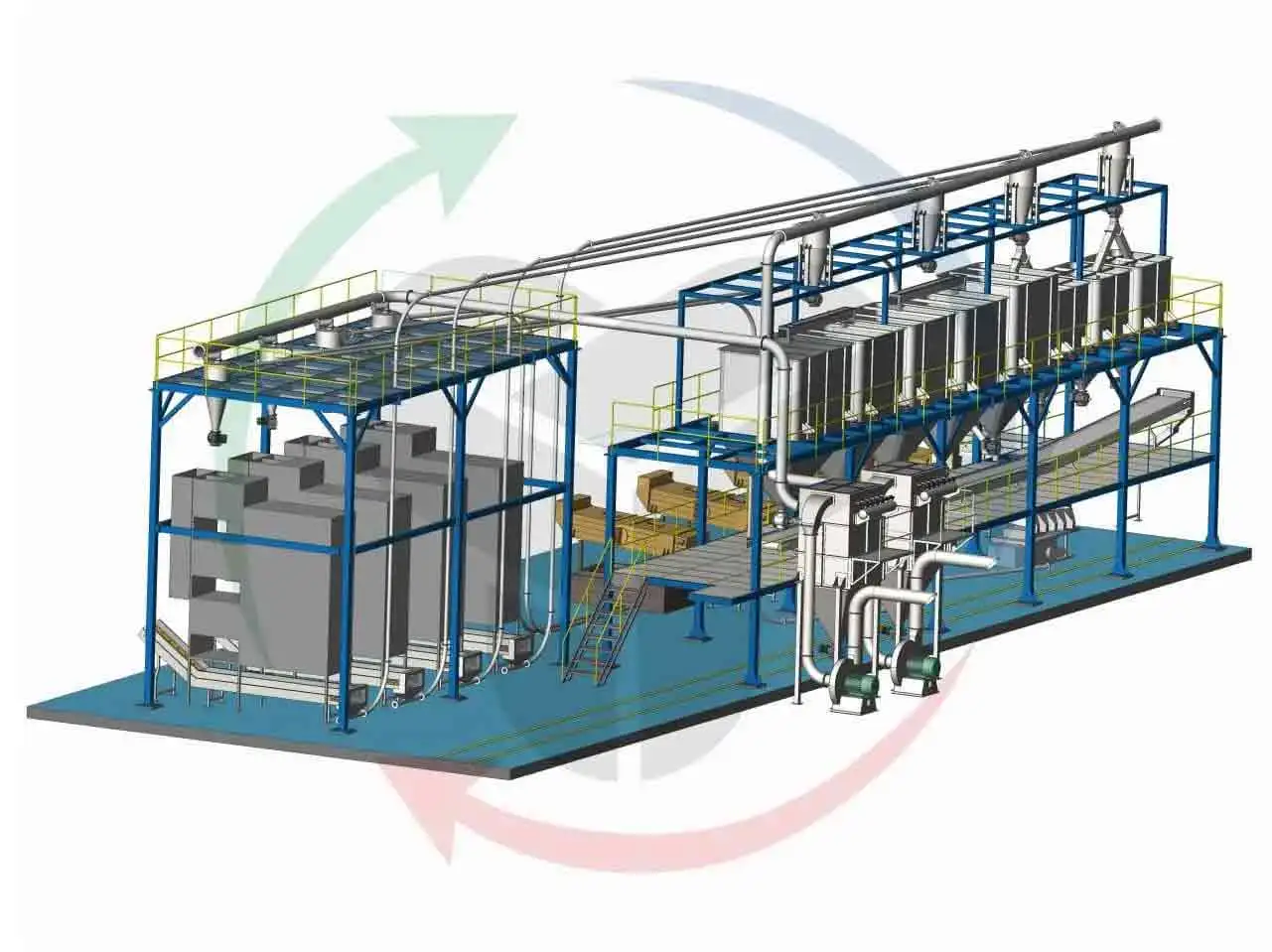

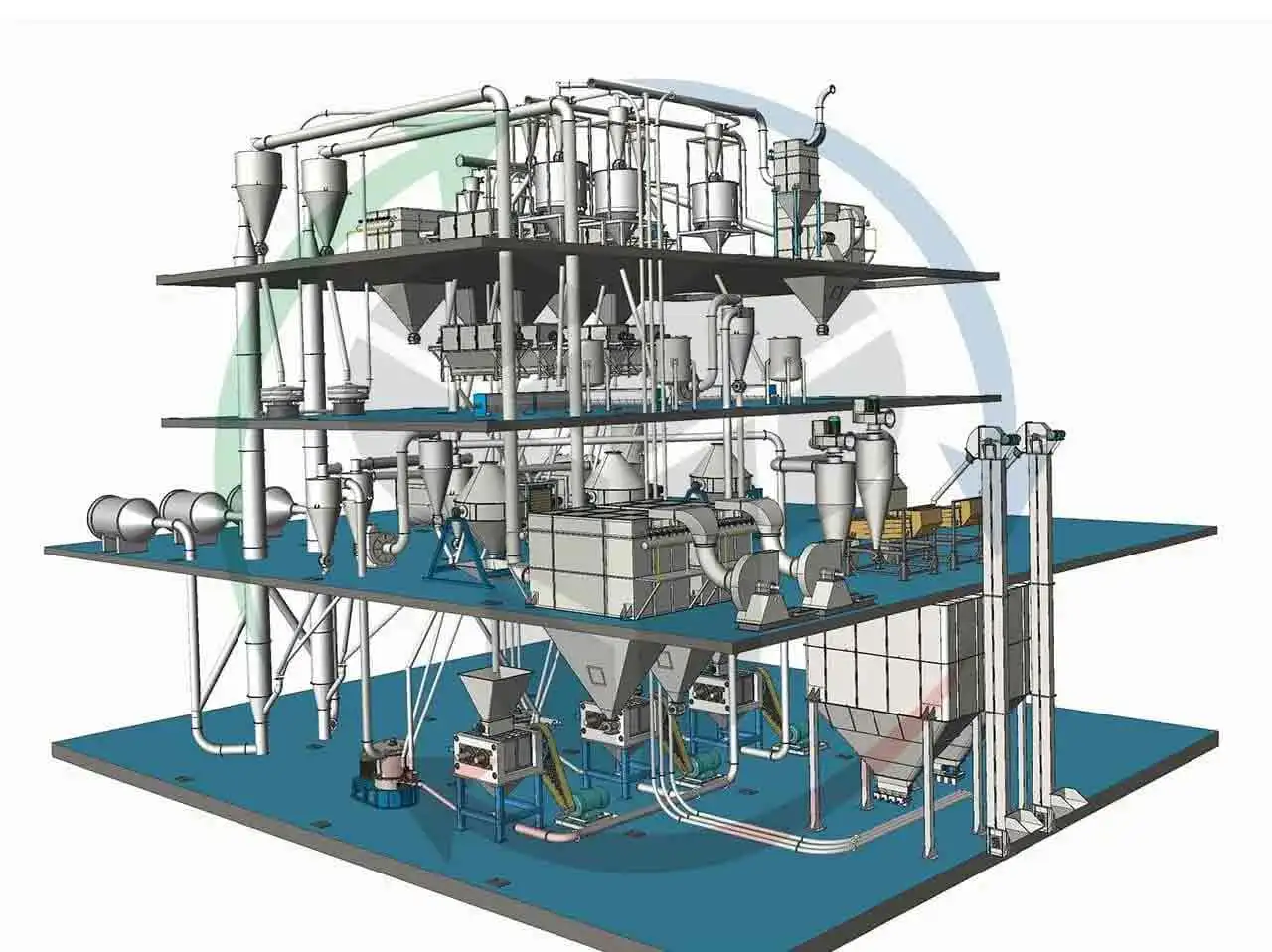

"SOLUTION FOR SIZE REDUCTION EQUIPMENT"

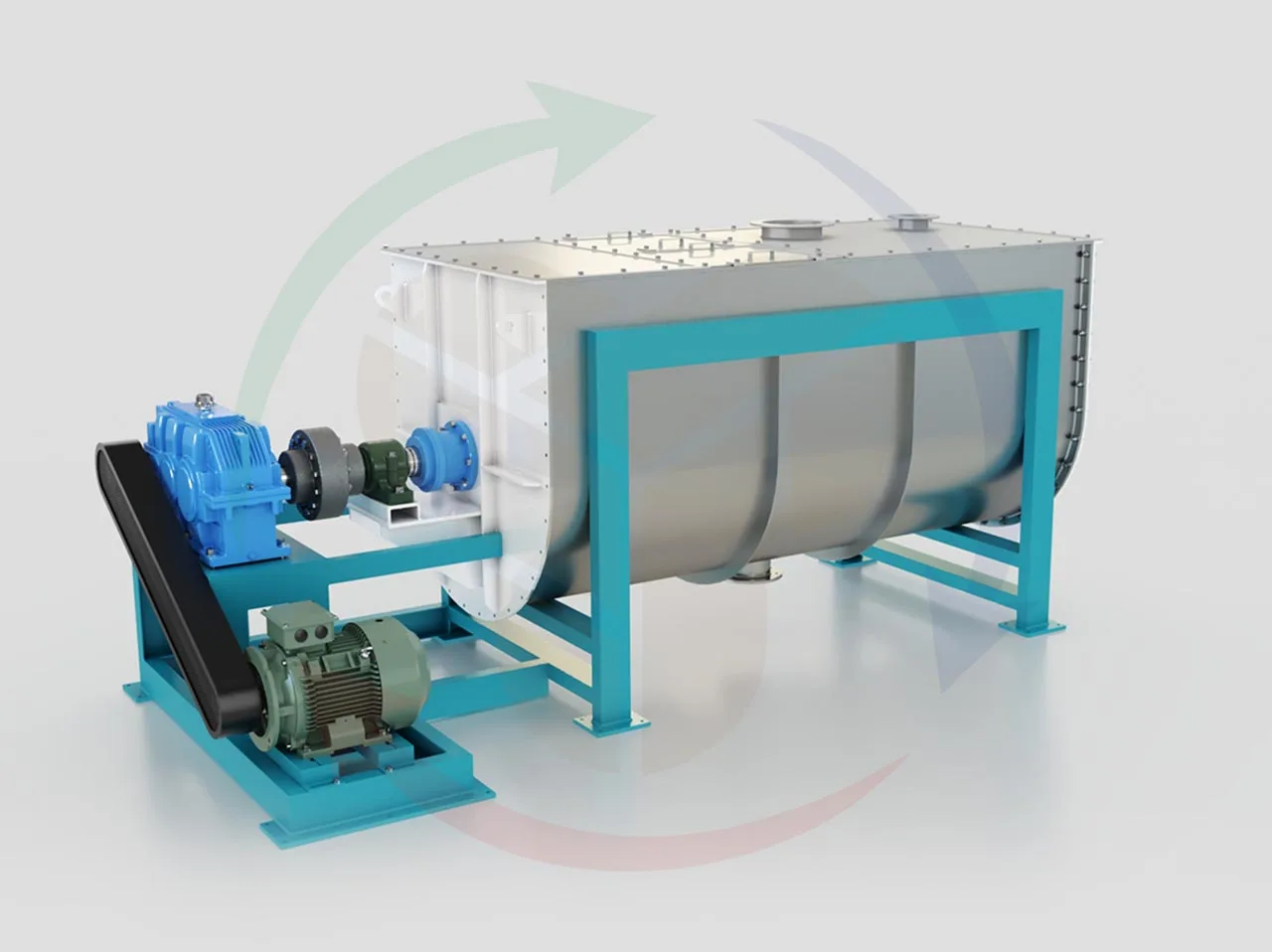

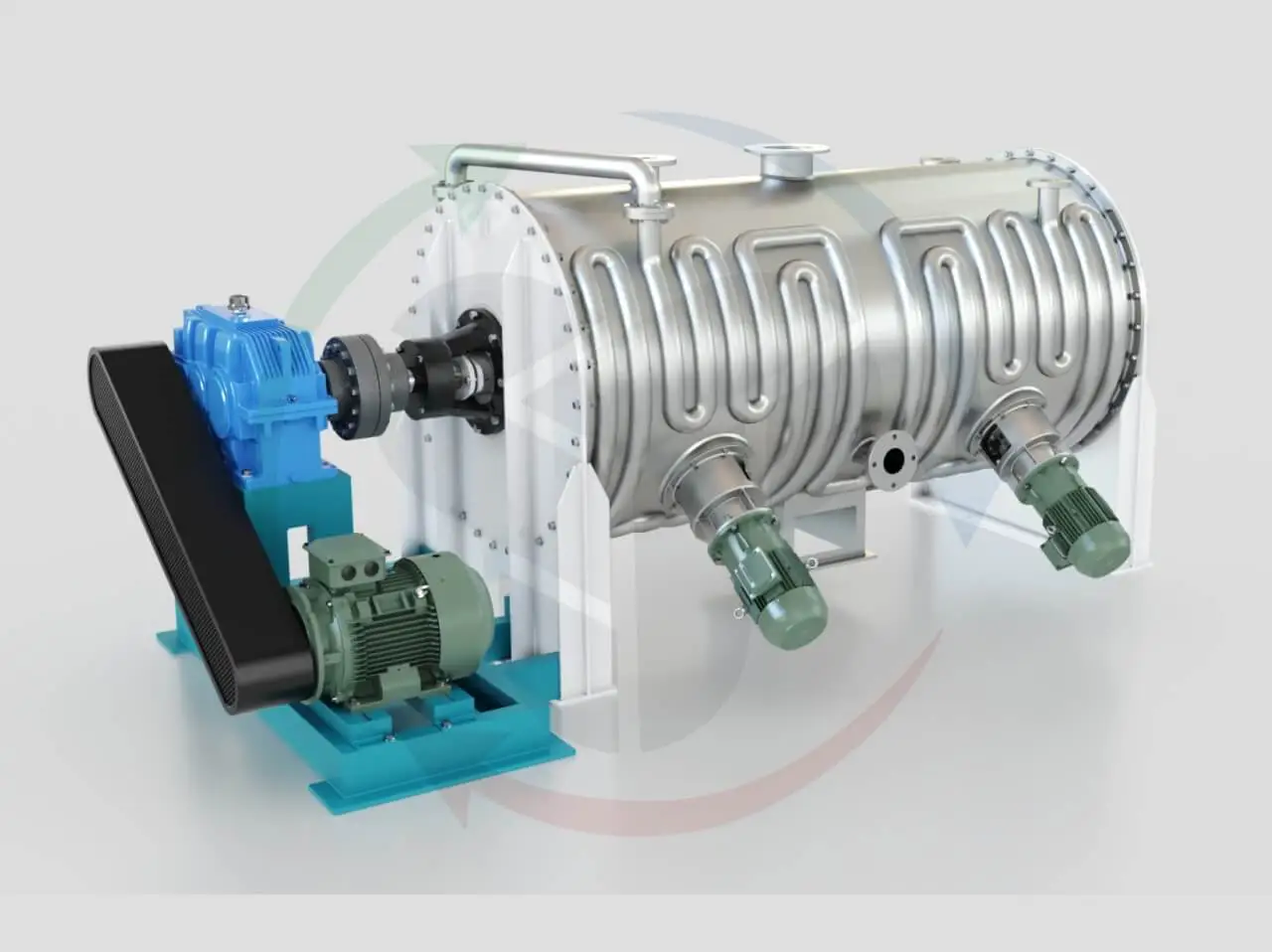

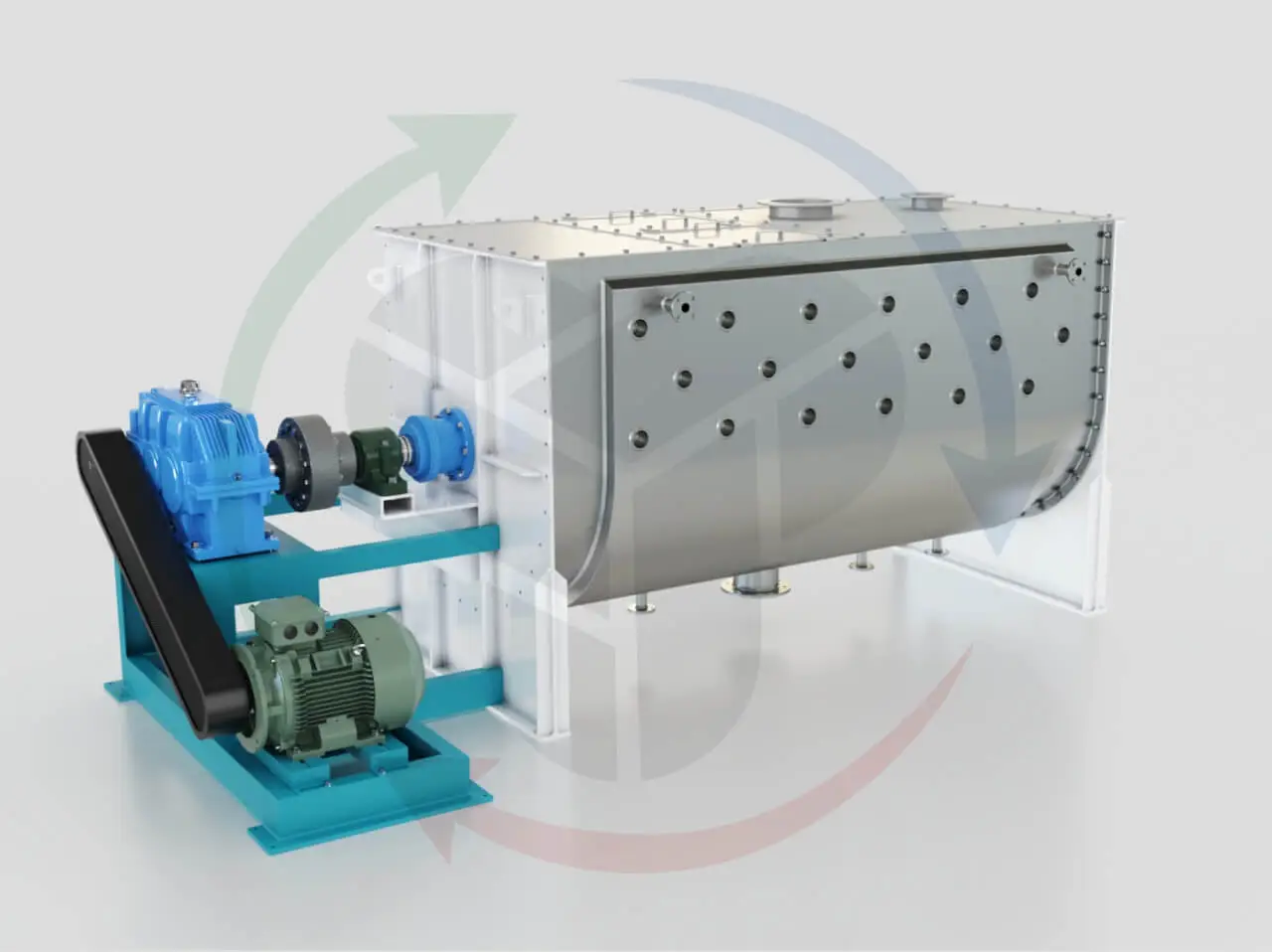

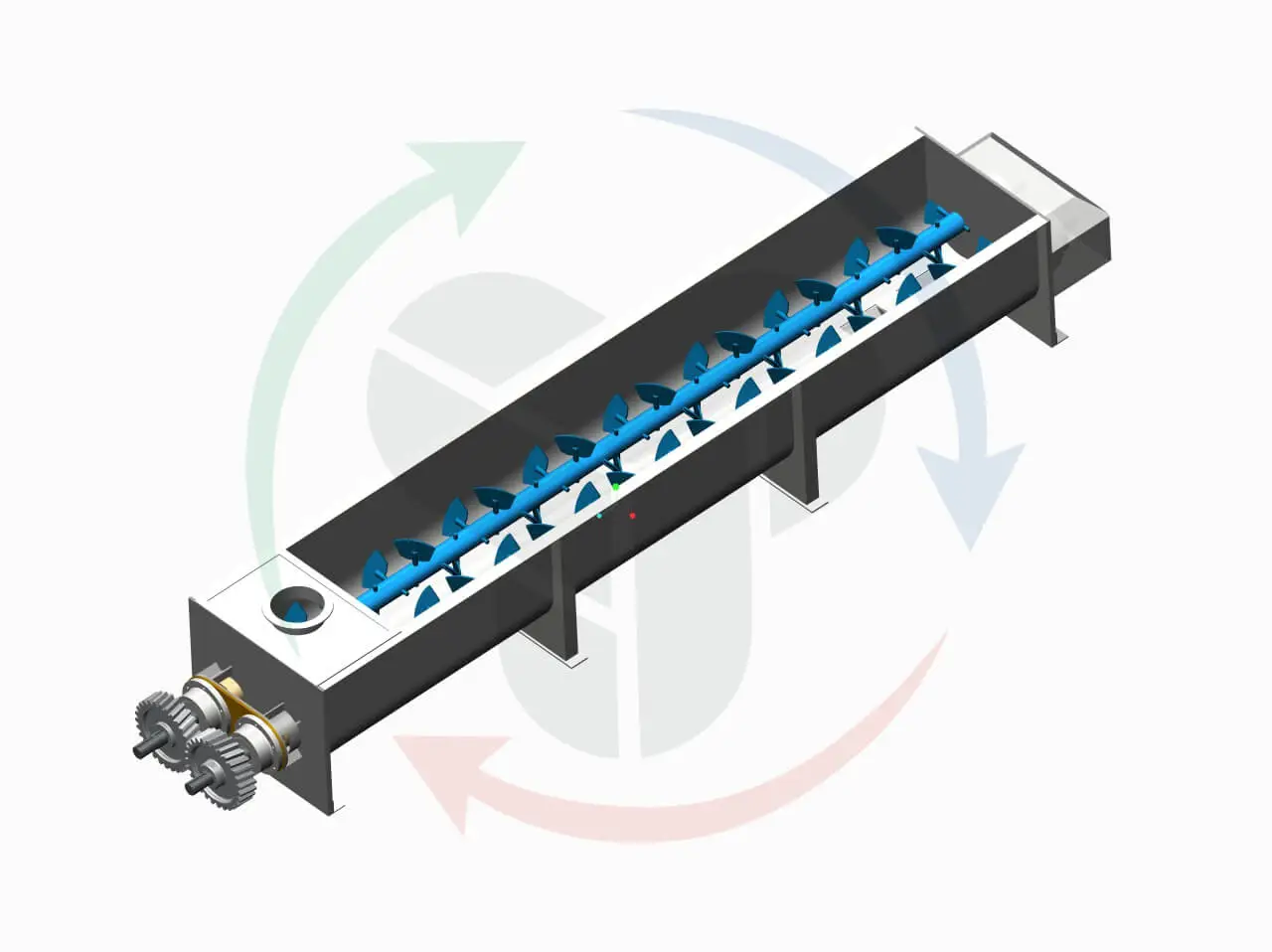

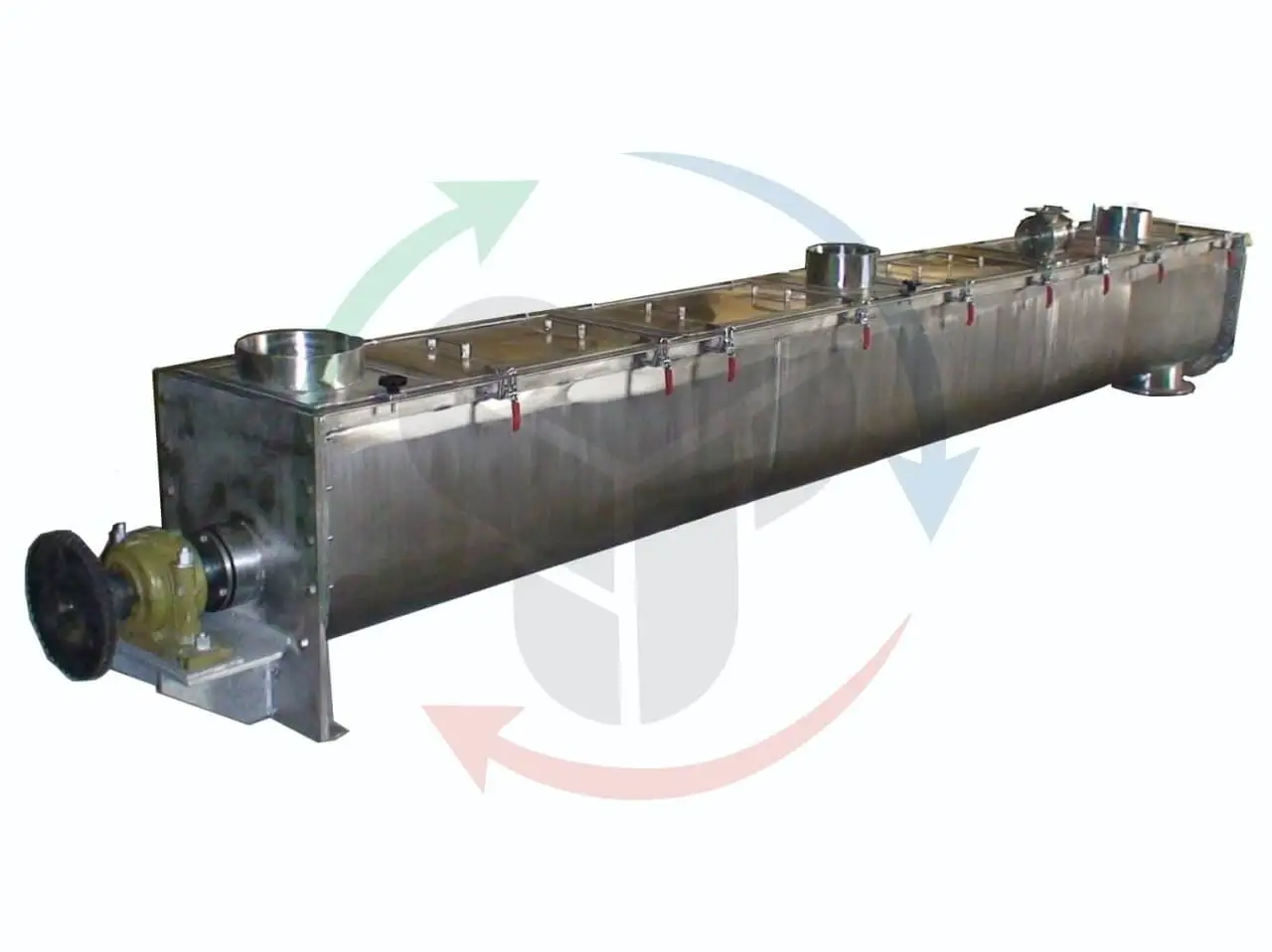

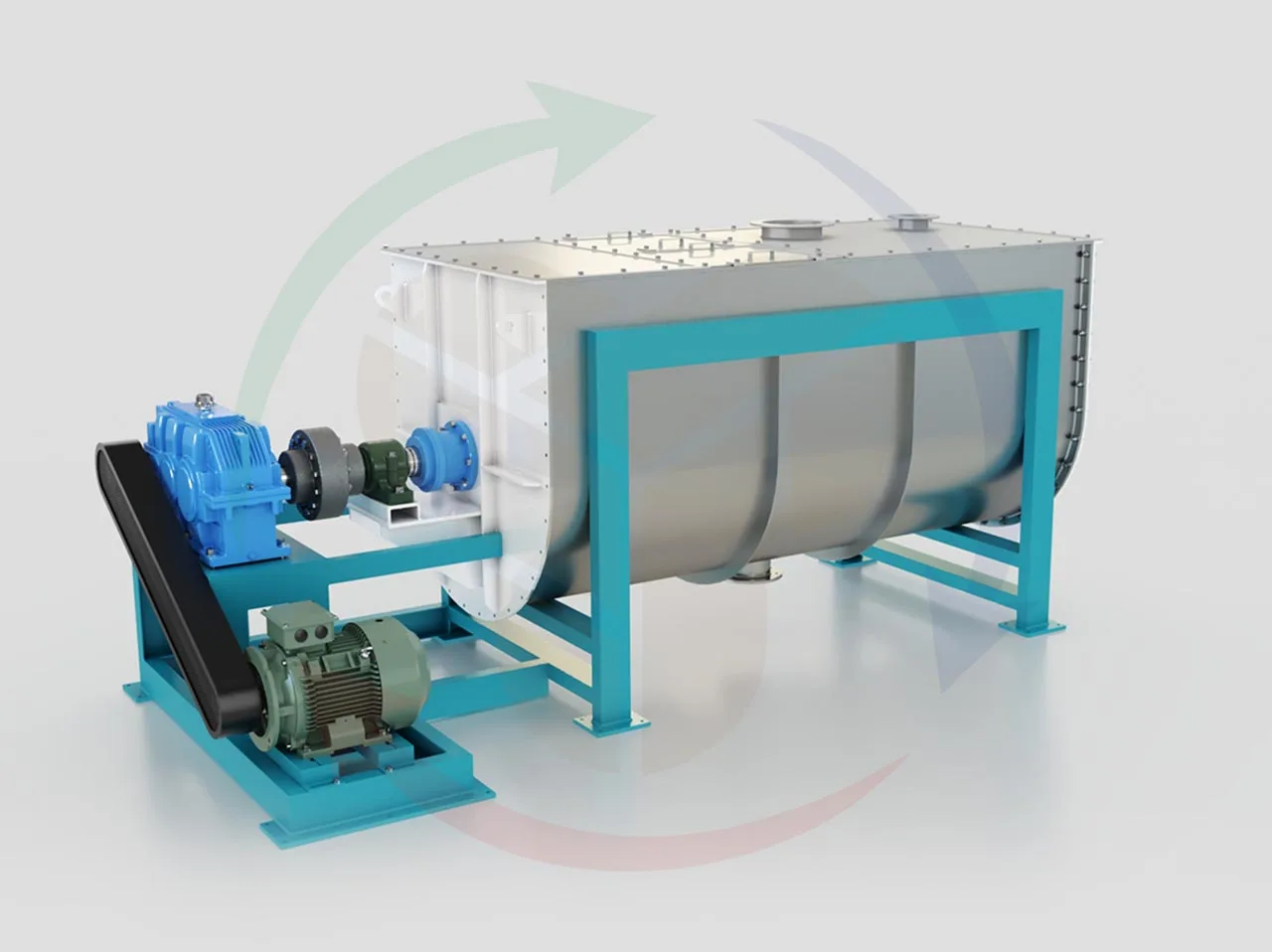

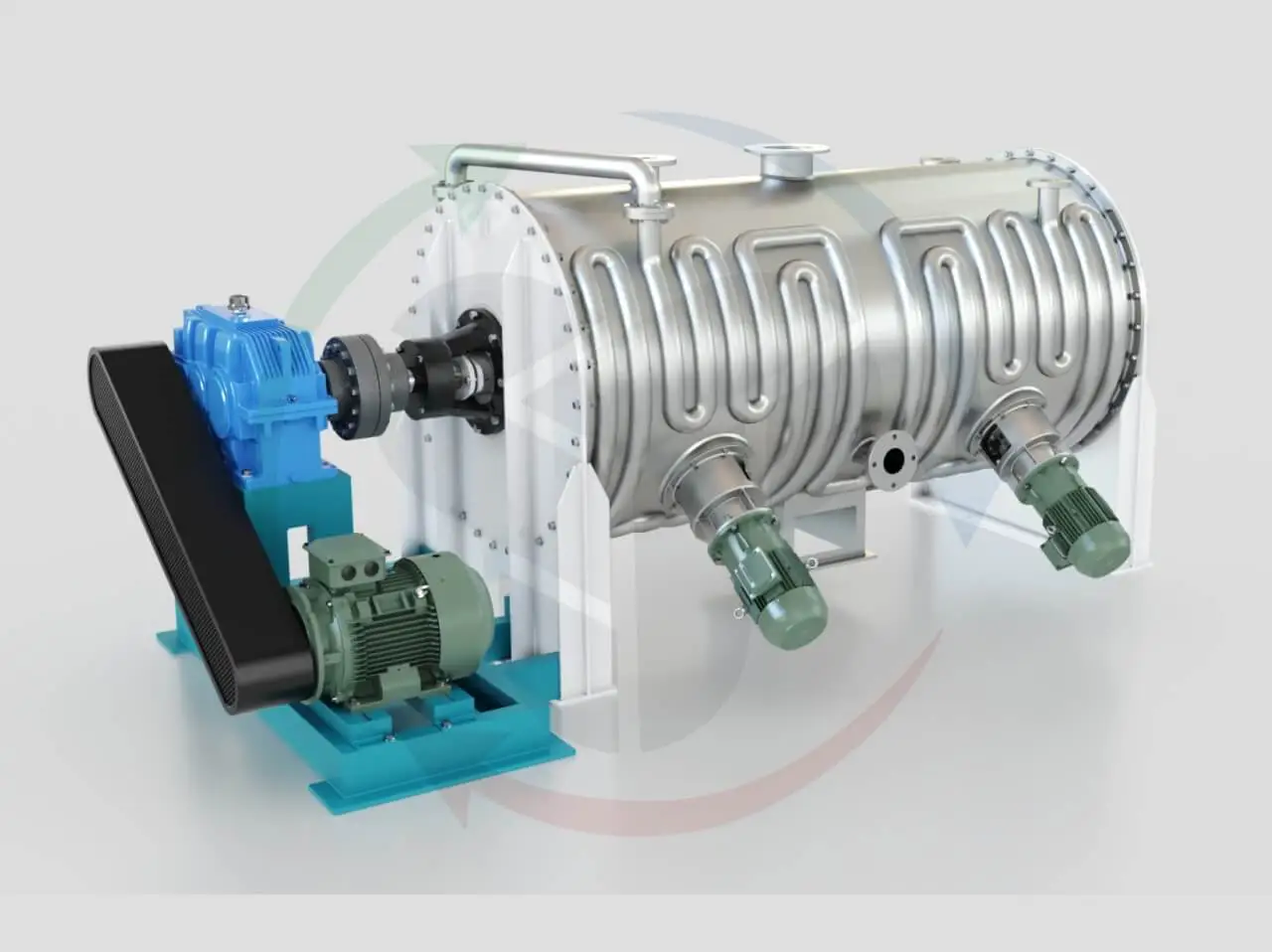

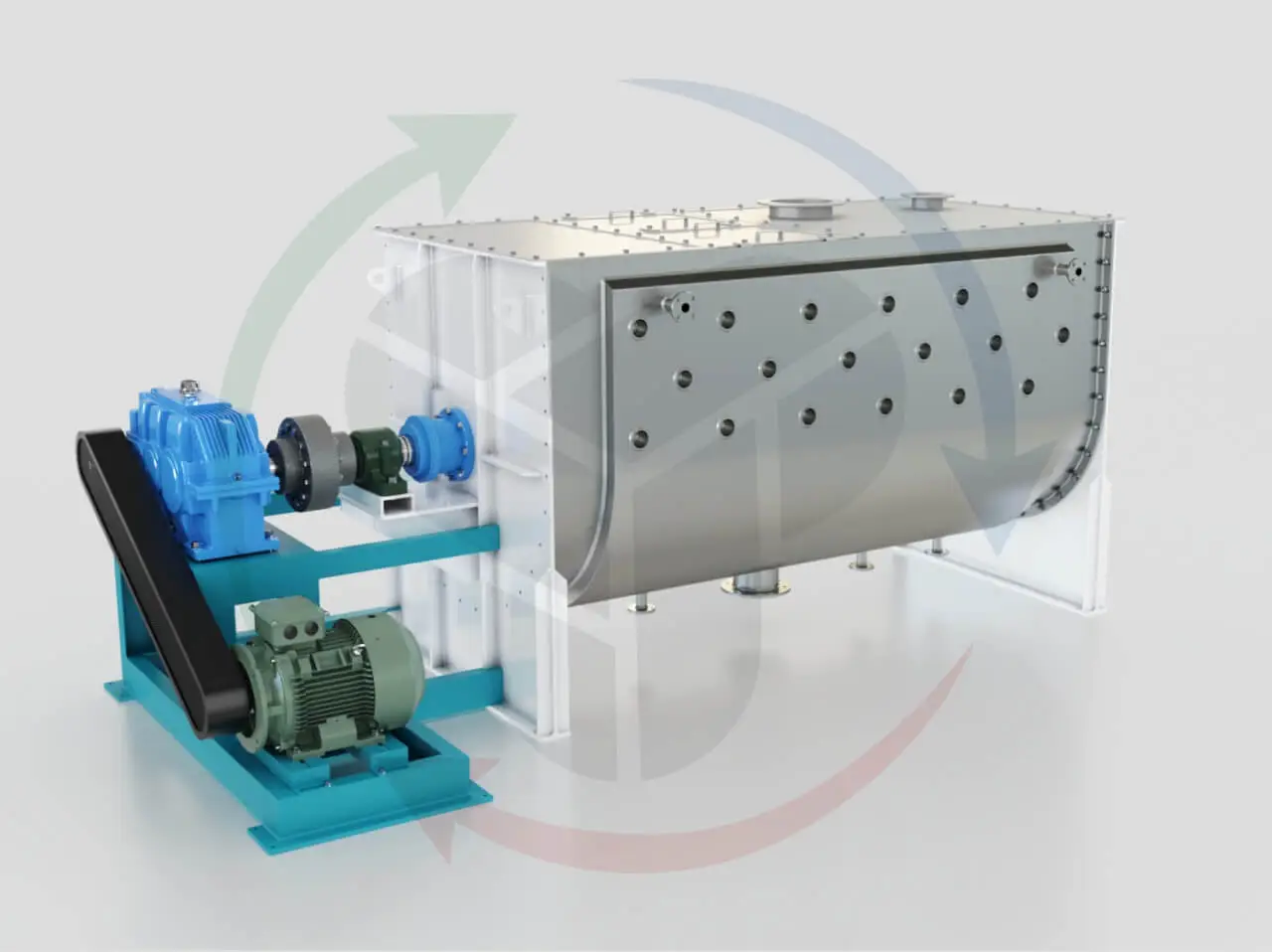

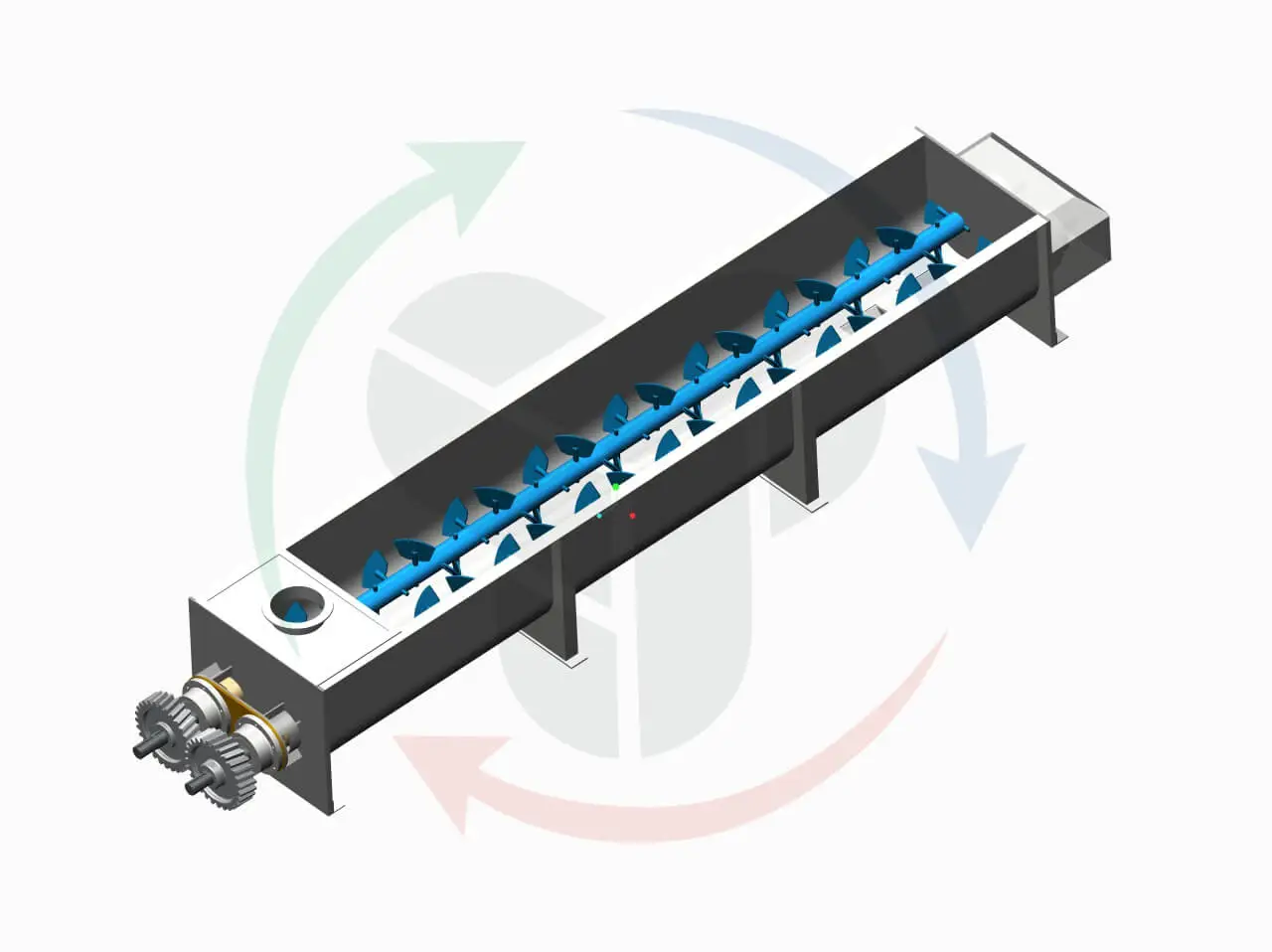

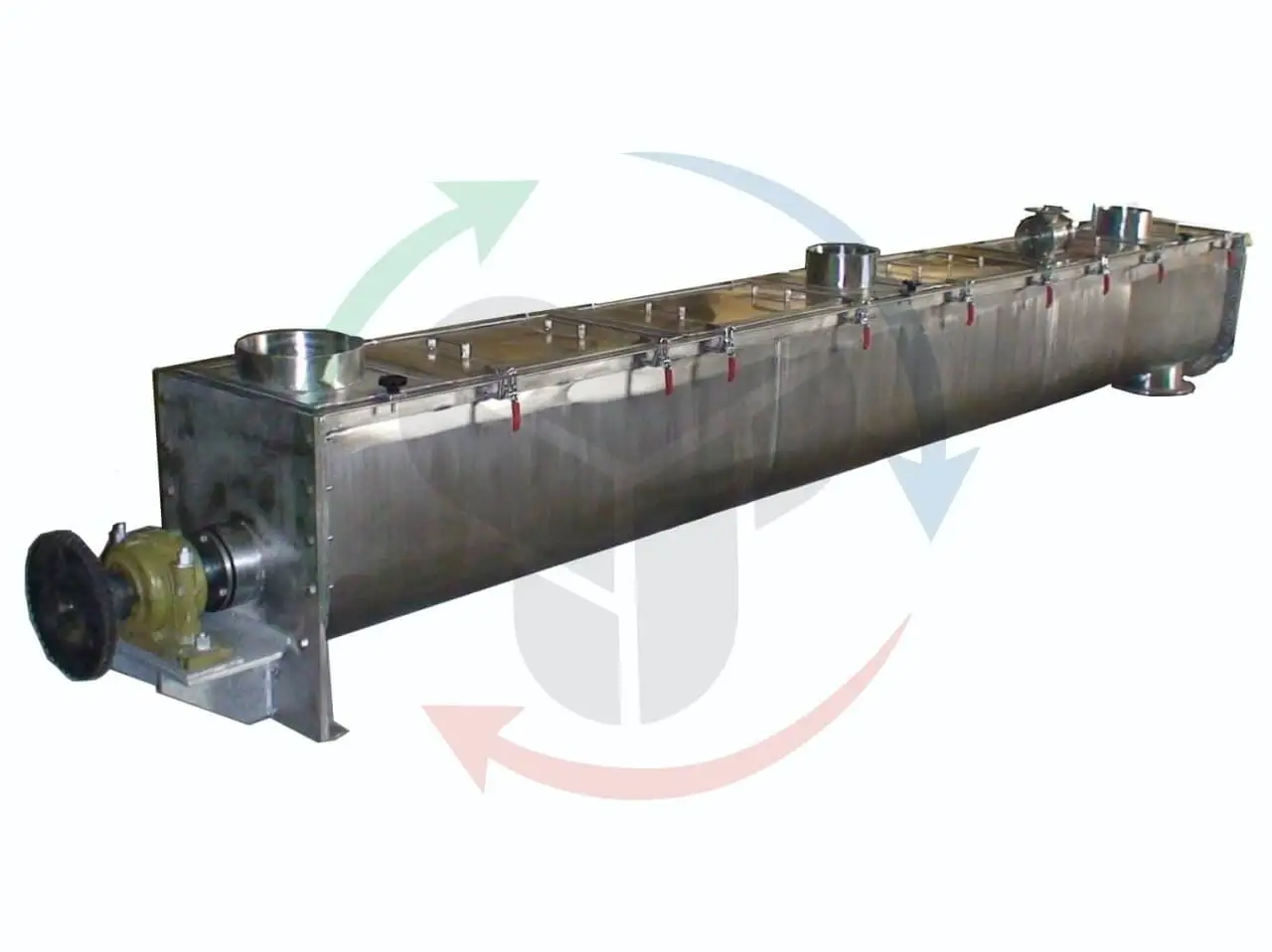

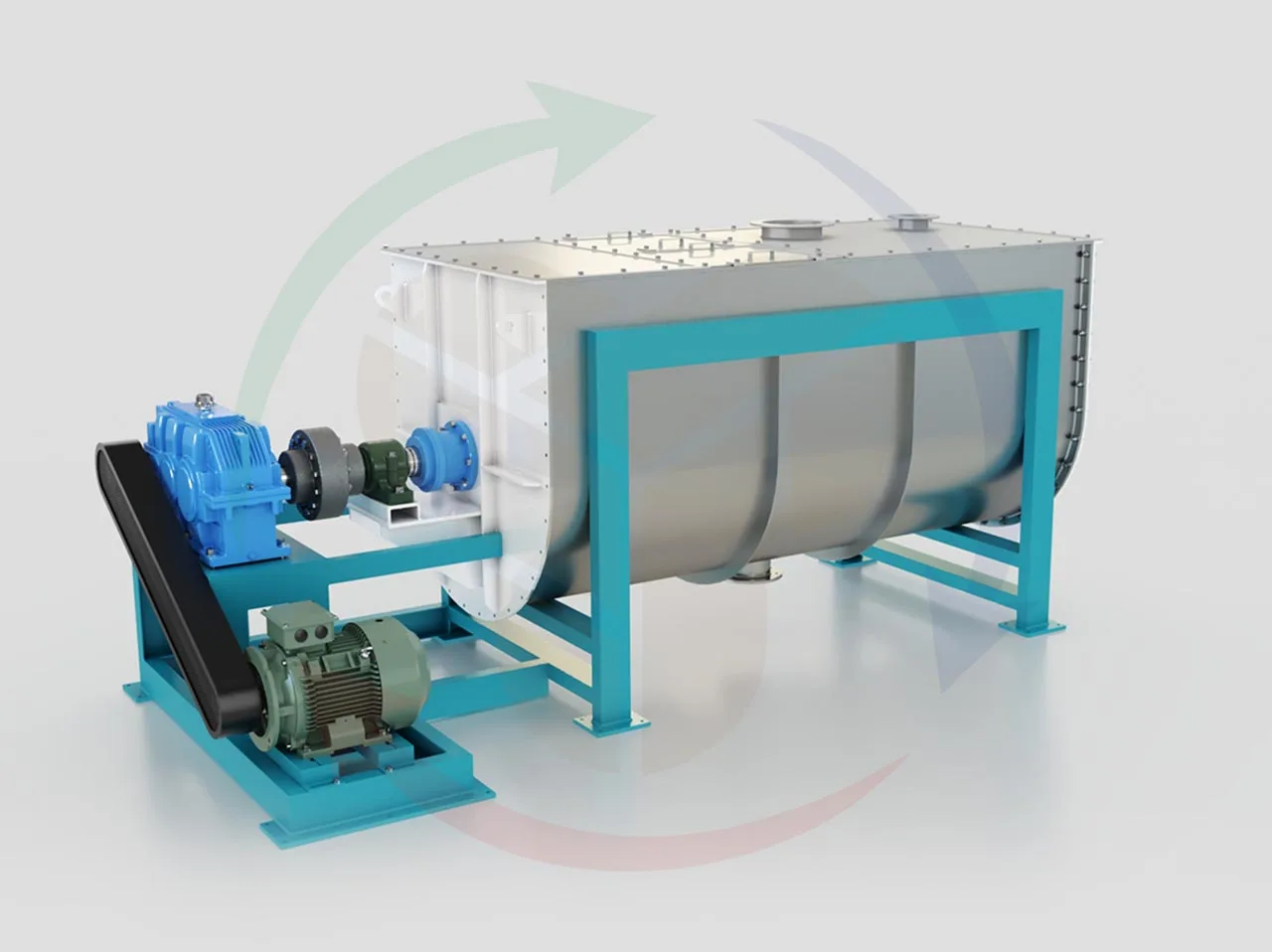

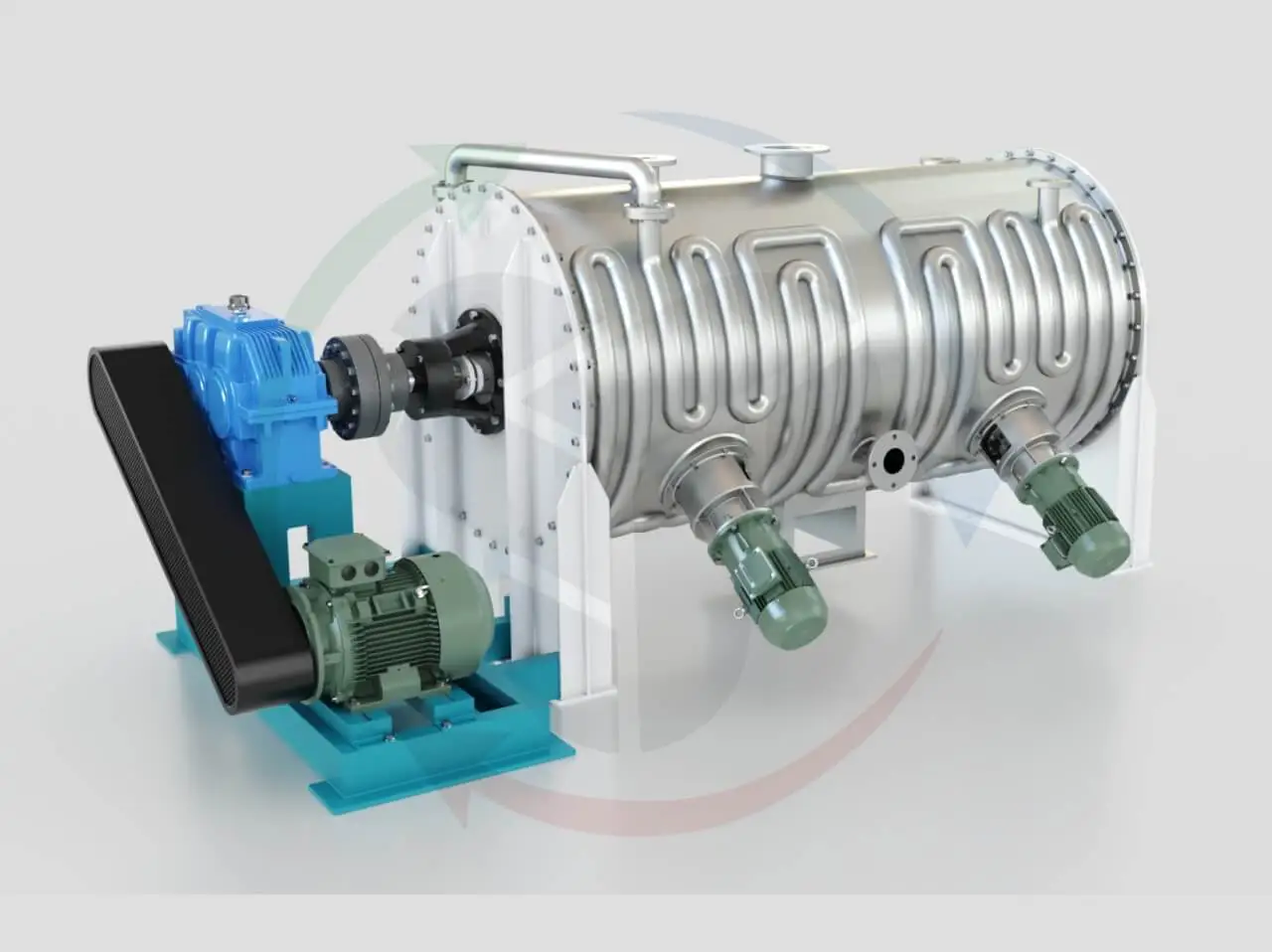

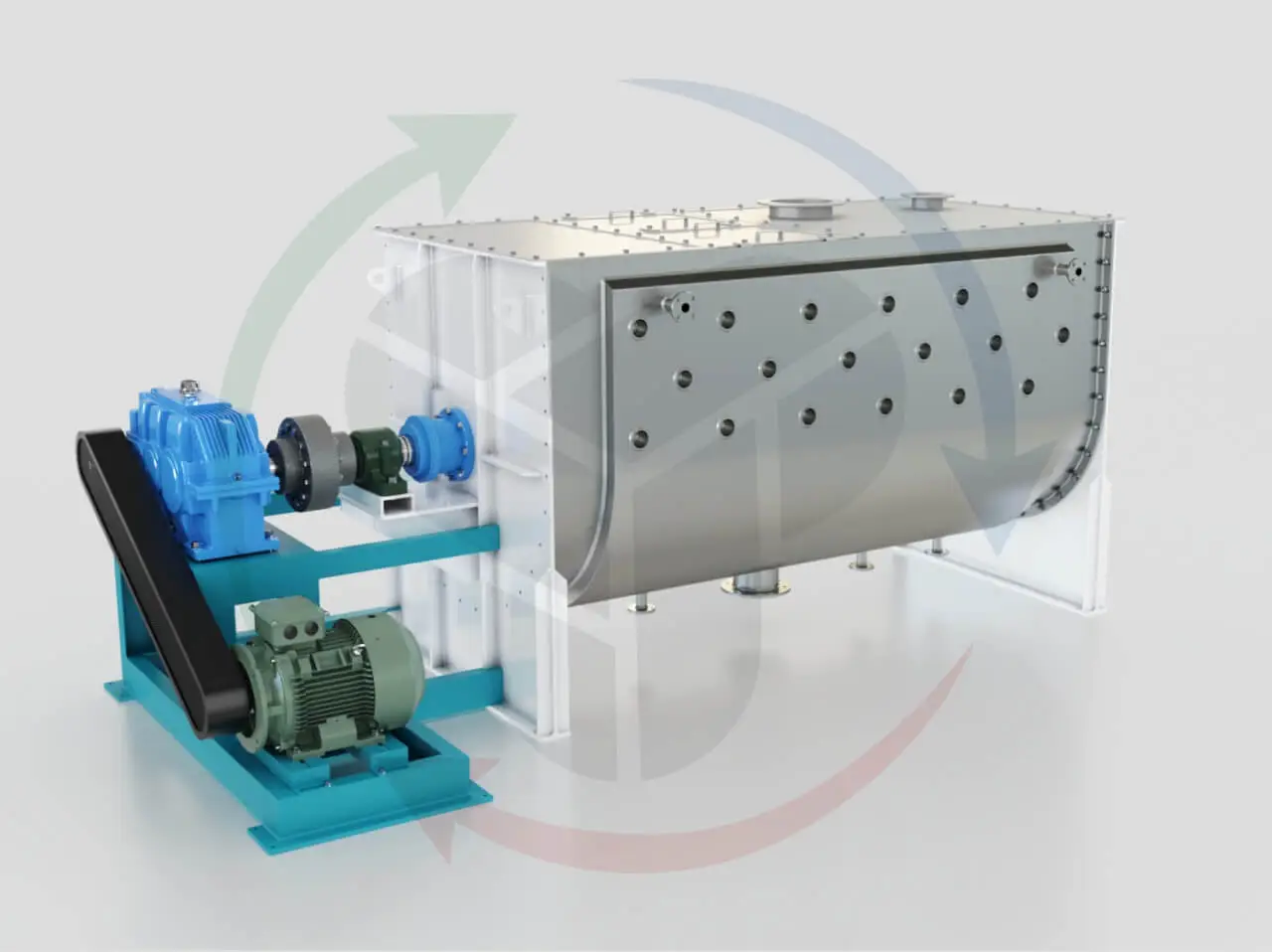

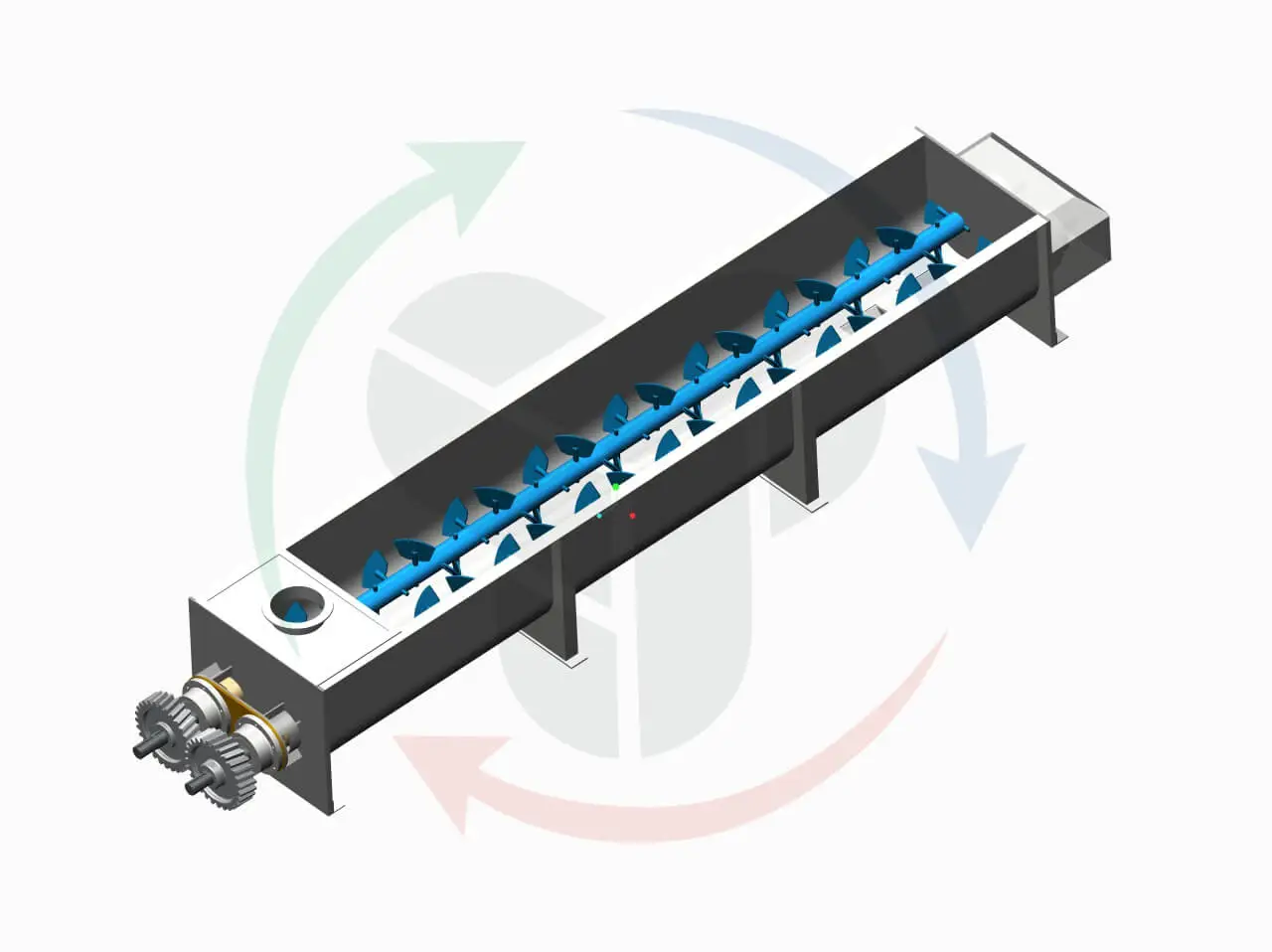

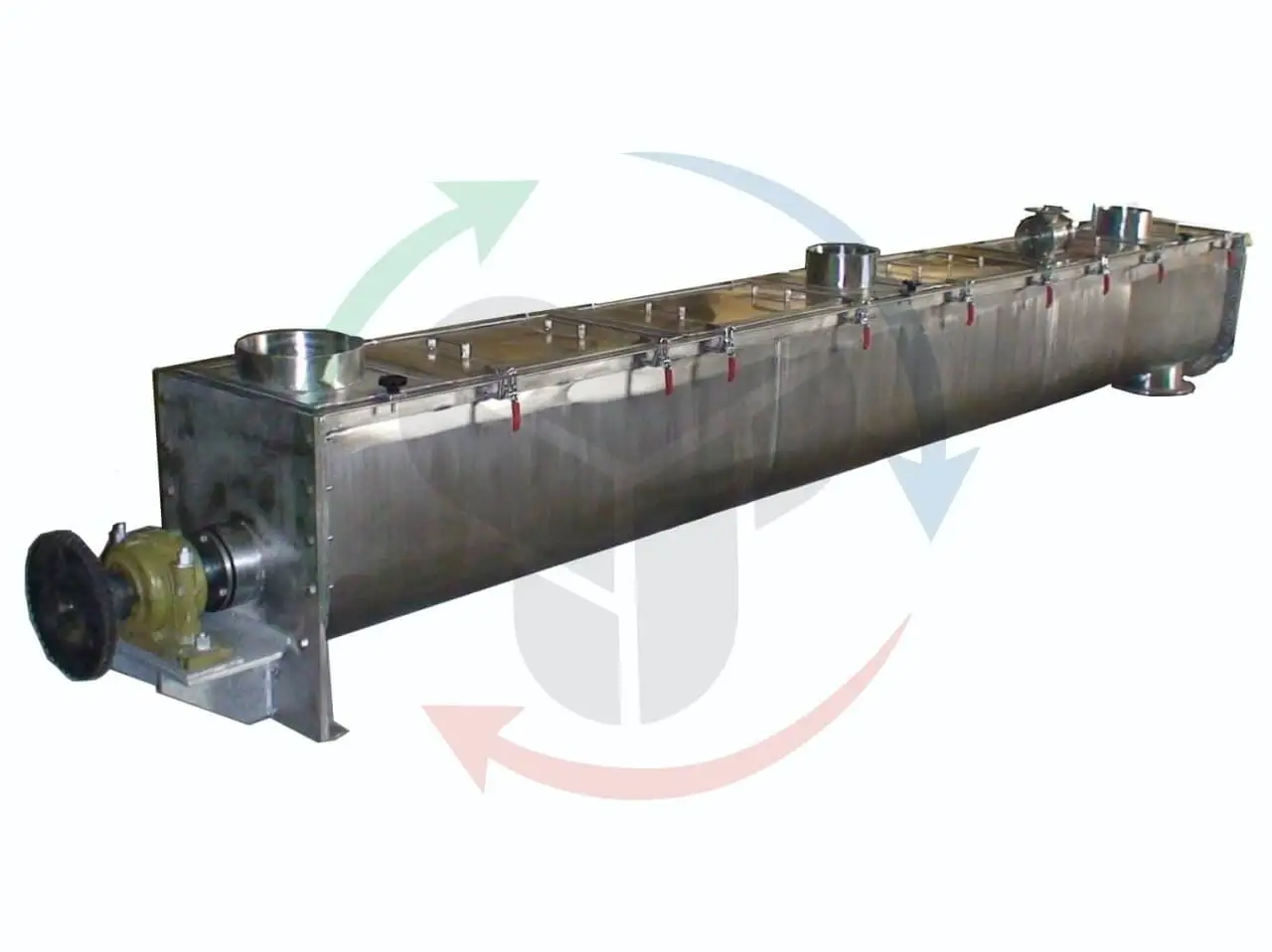

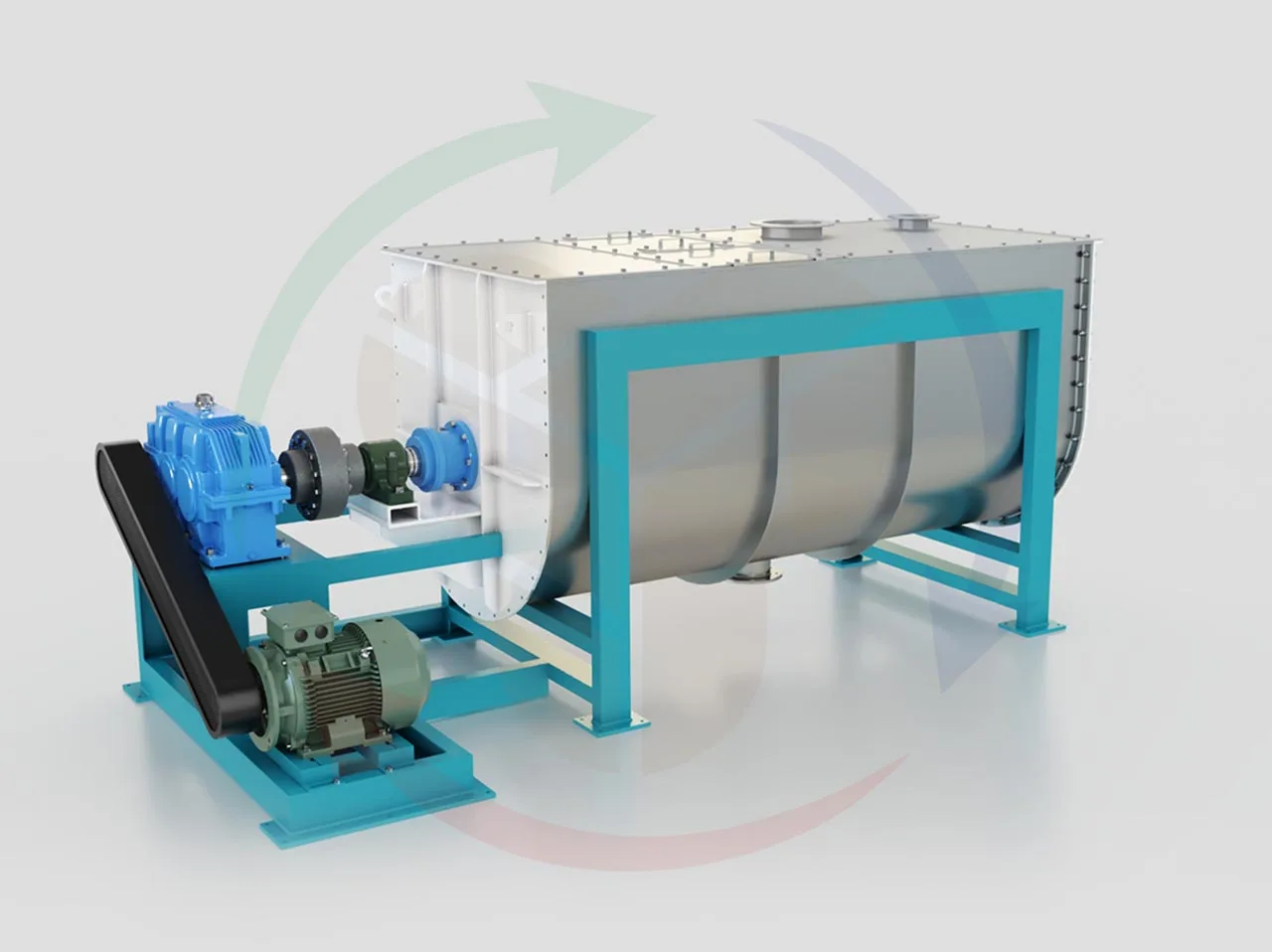

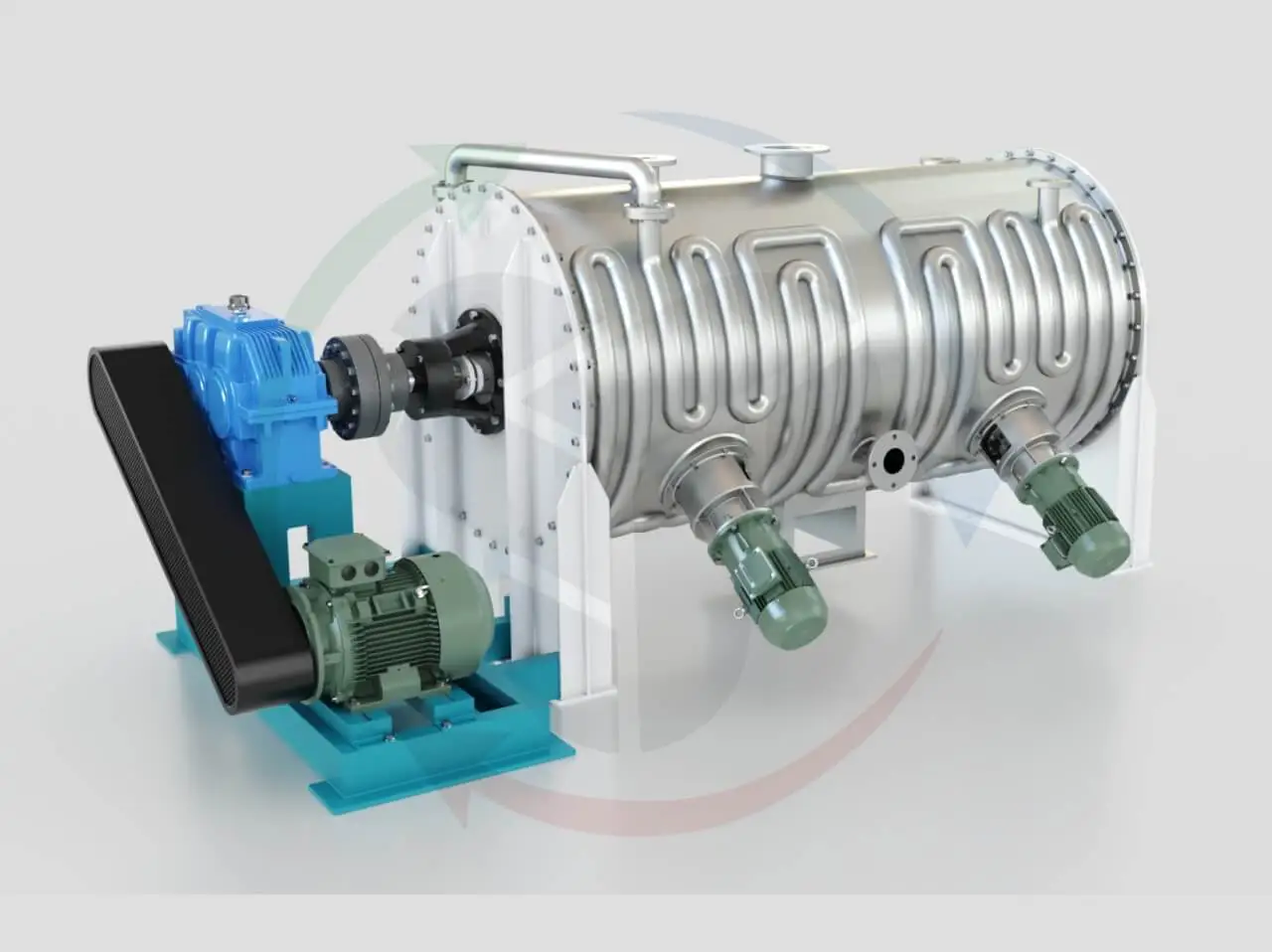

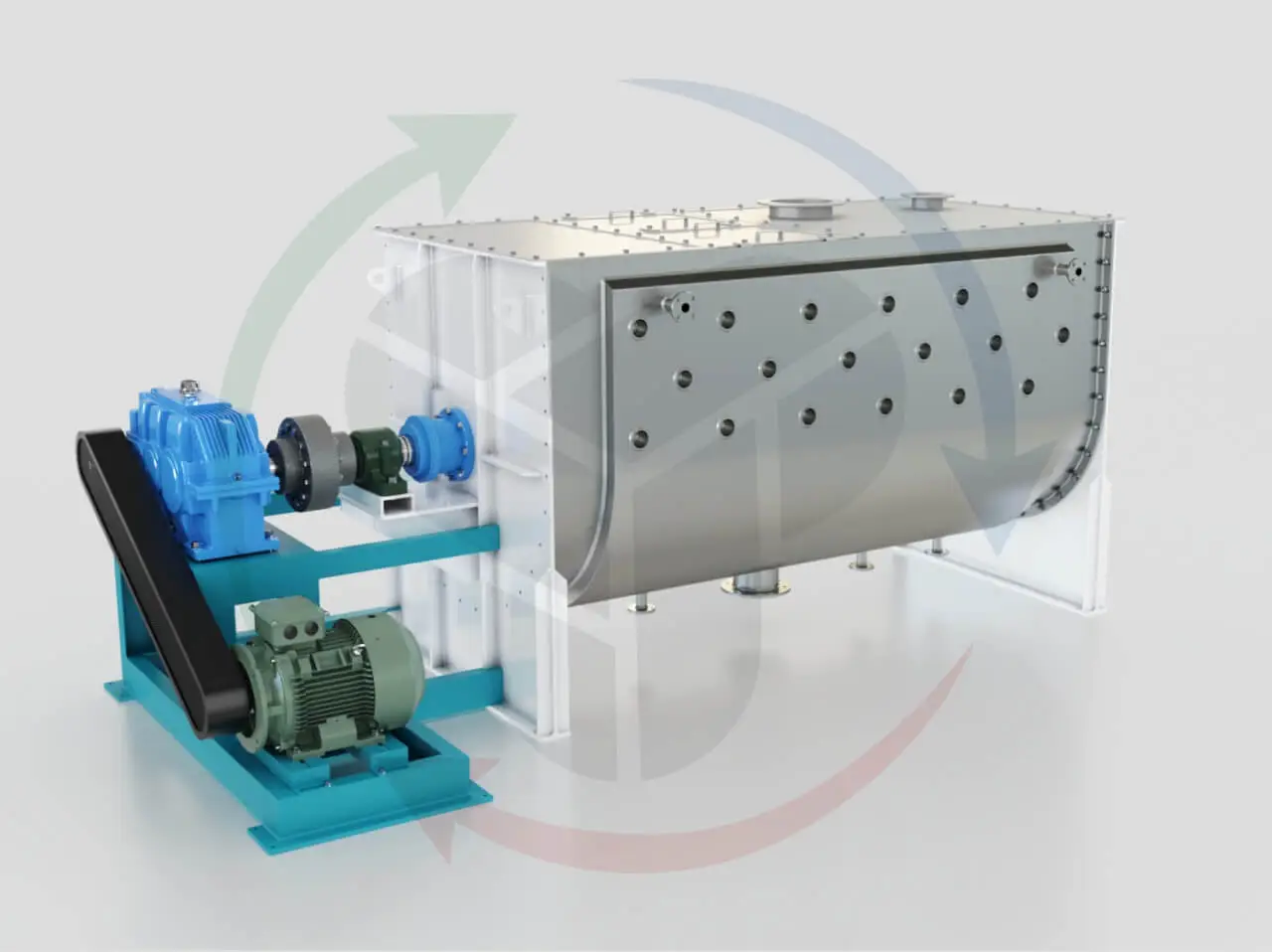

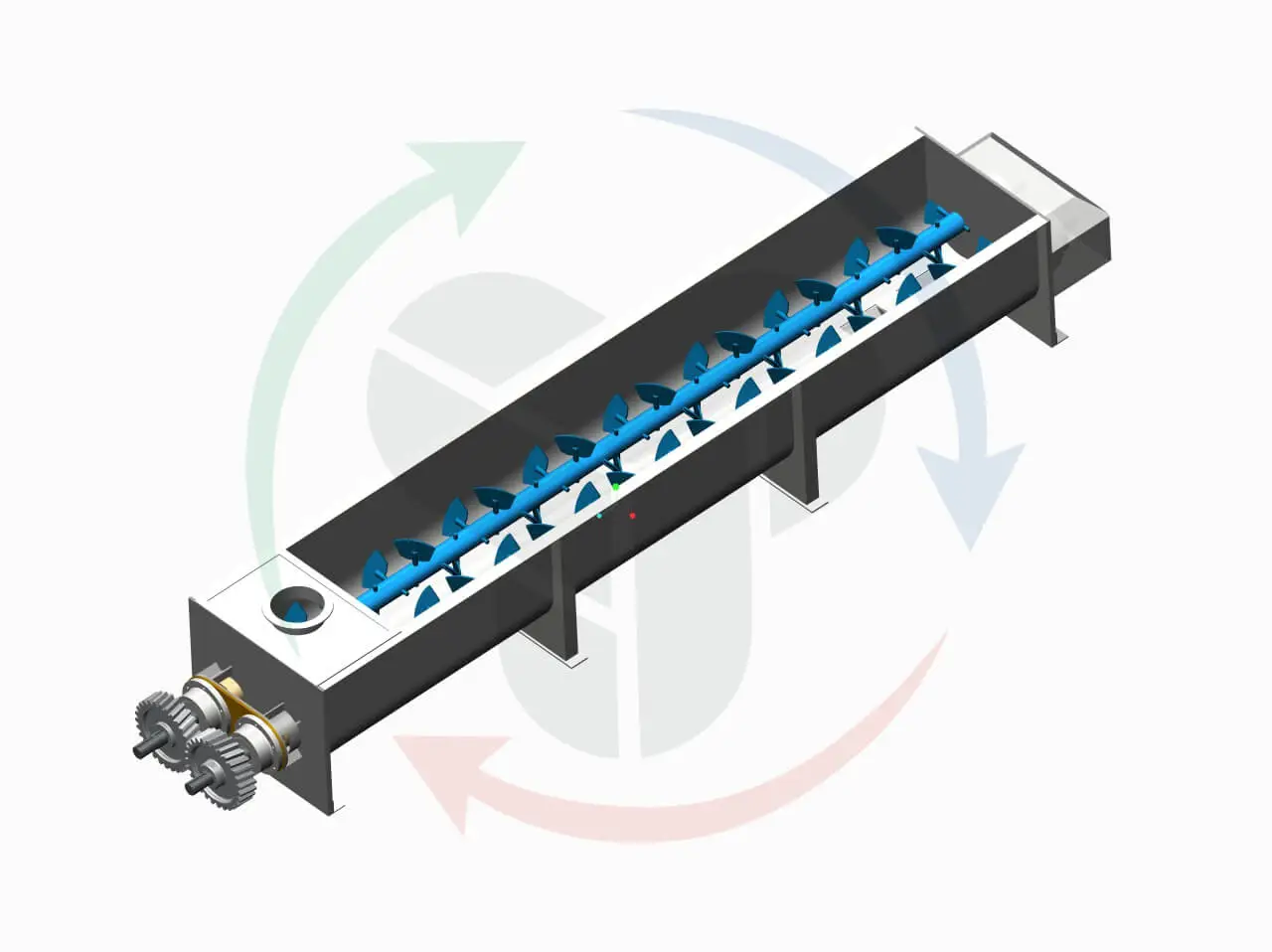

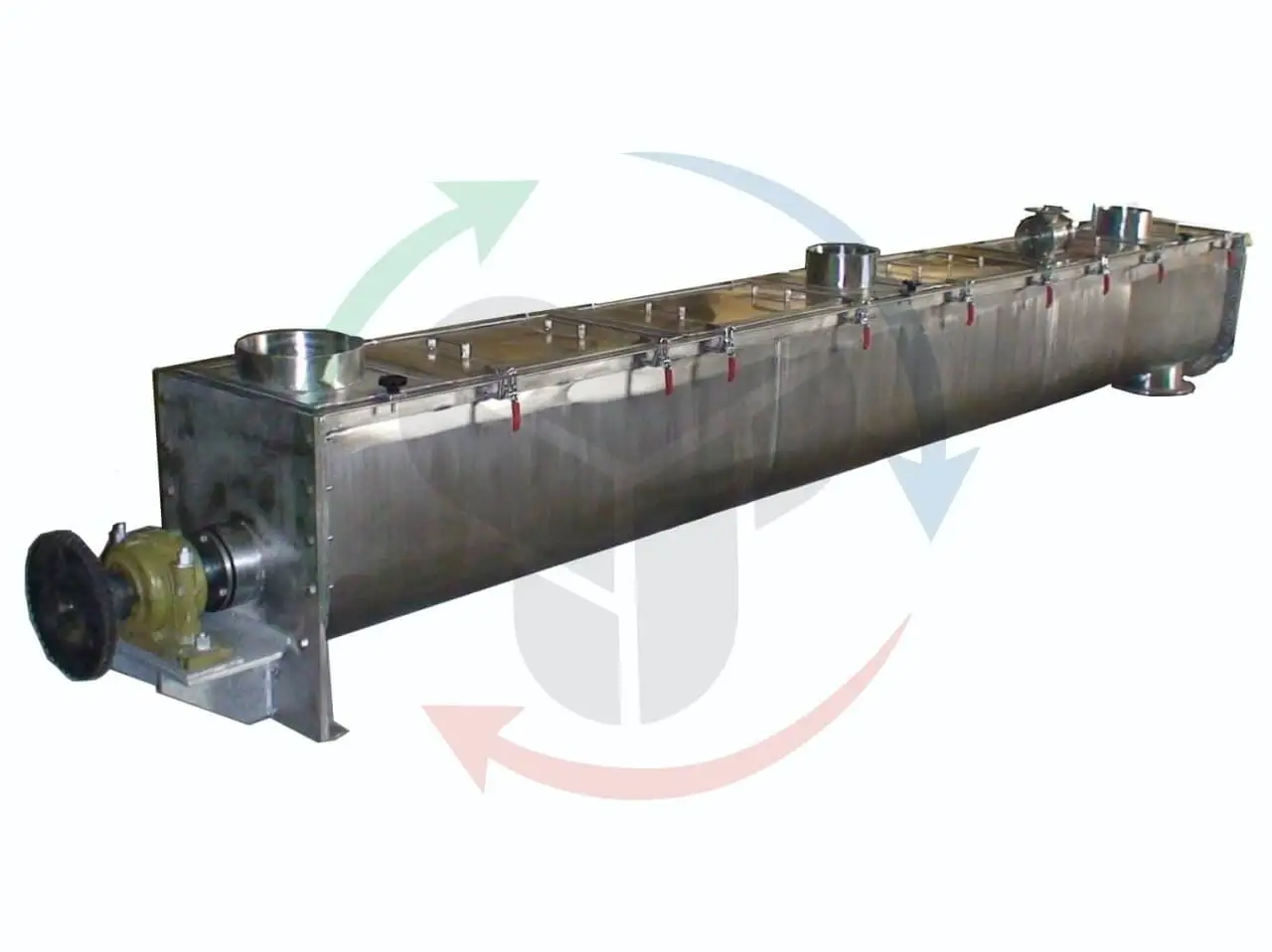

"SOLUTION FOR MIXING EQUIPMENT"

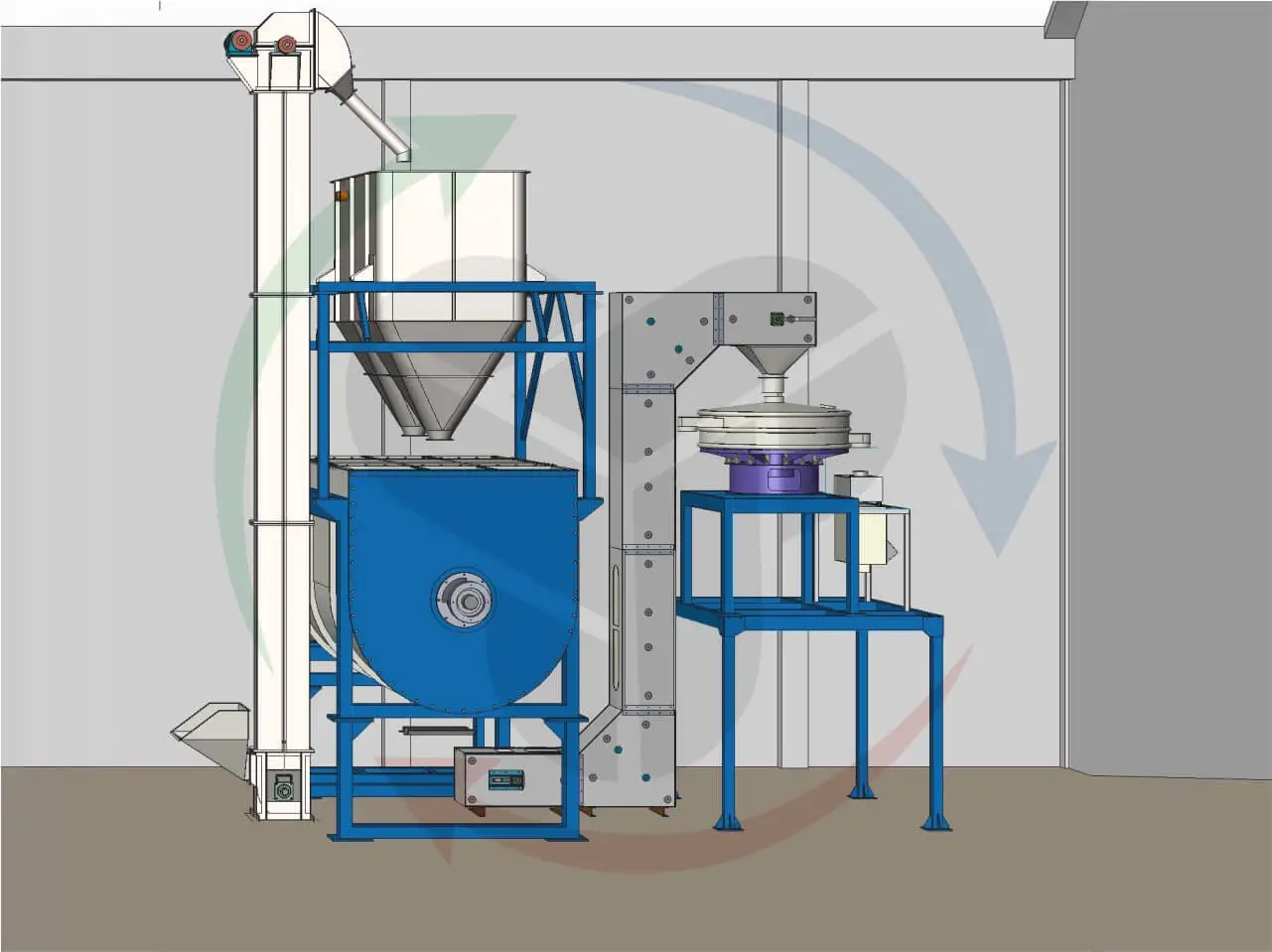

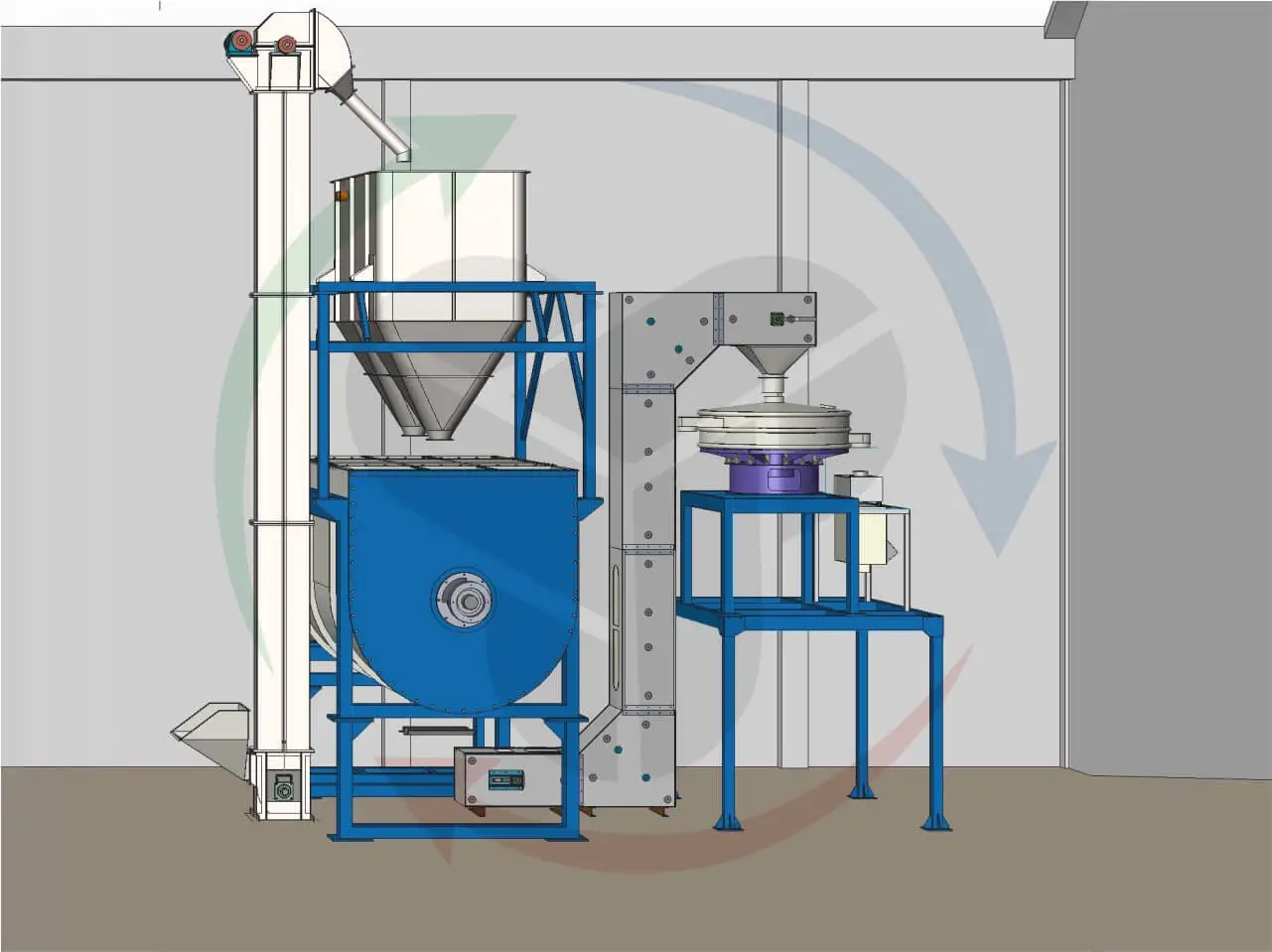

"SOLUTION FOR GRADATION EQUIPMENT"

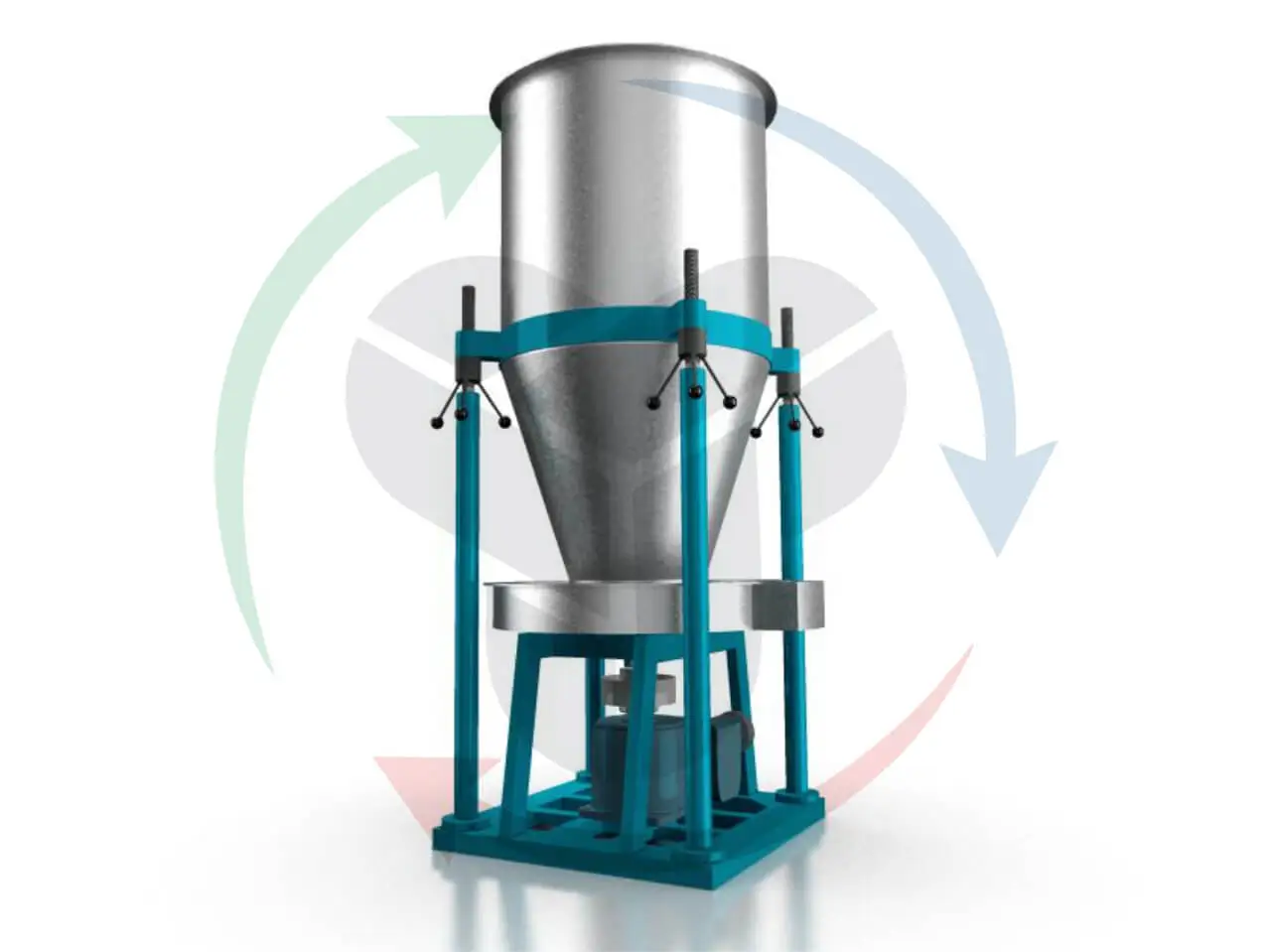

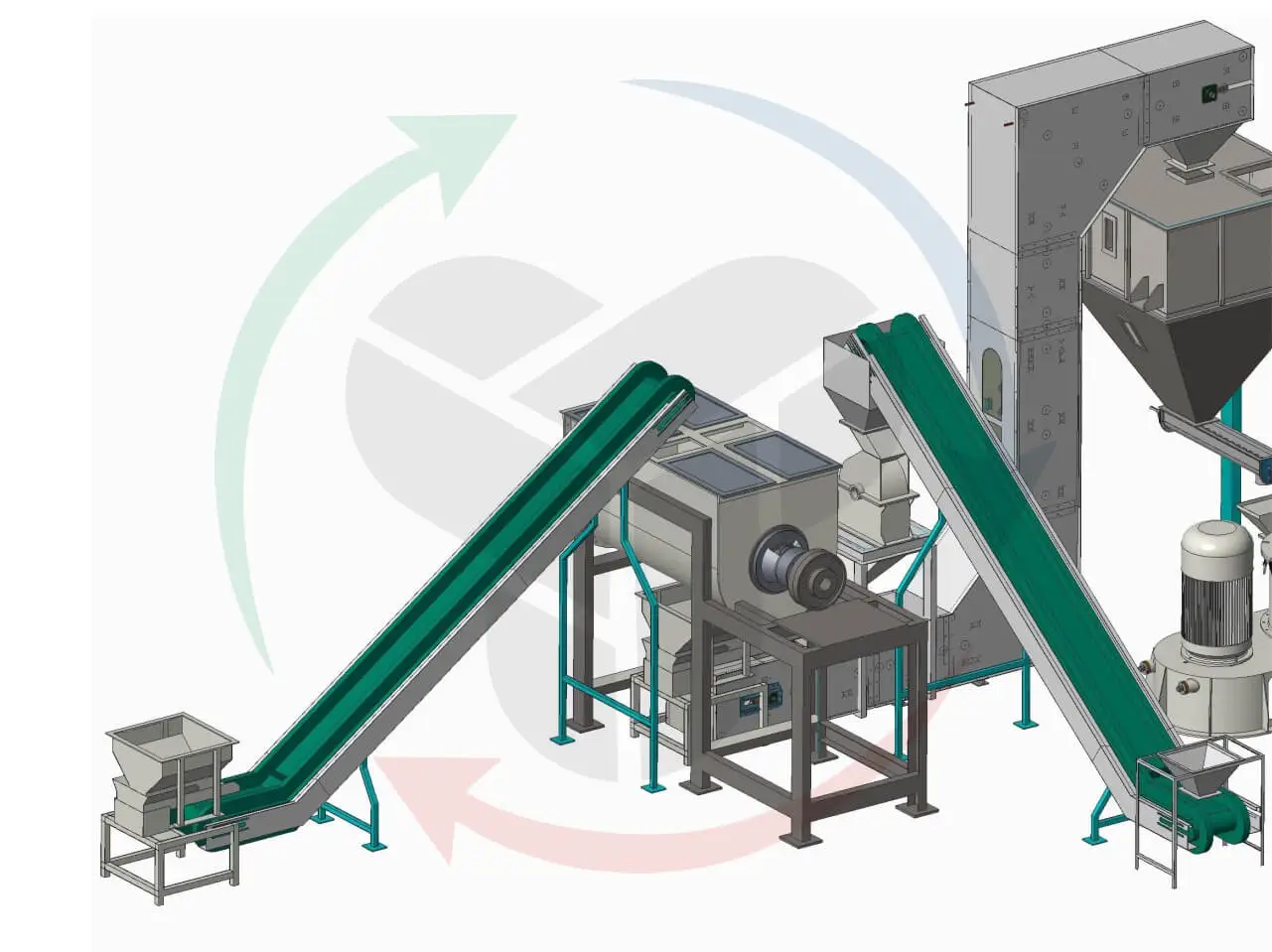

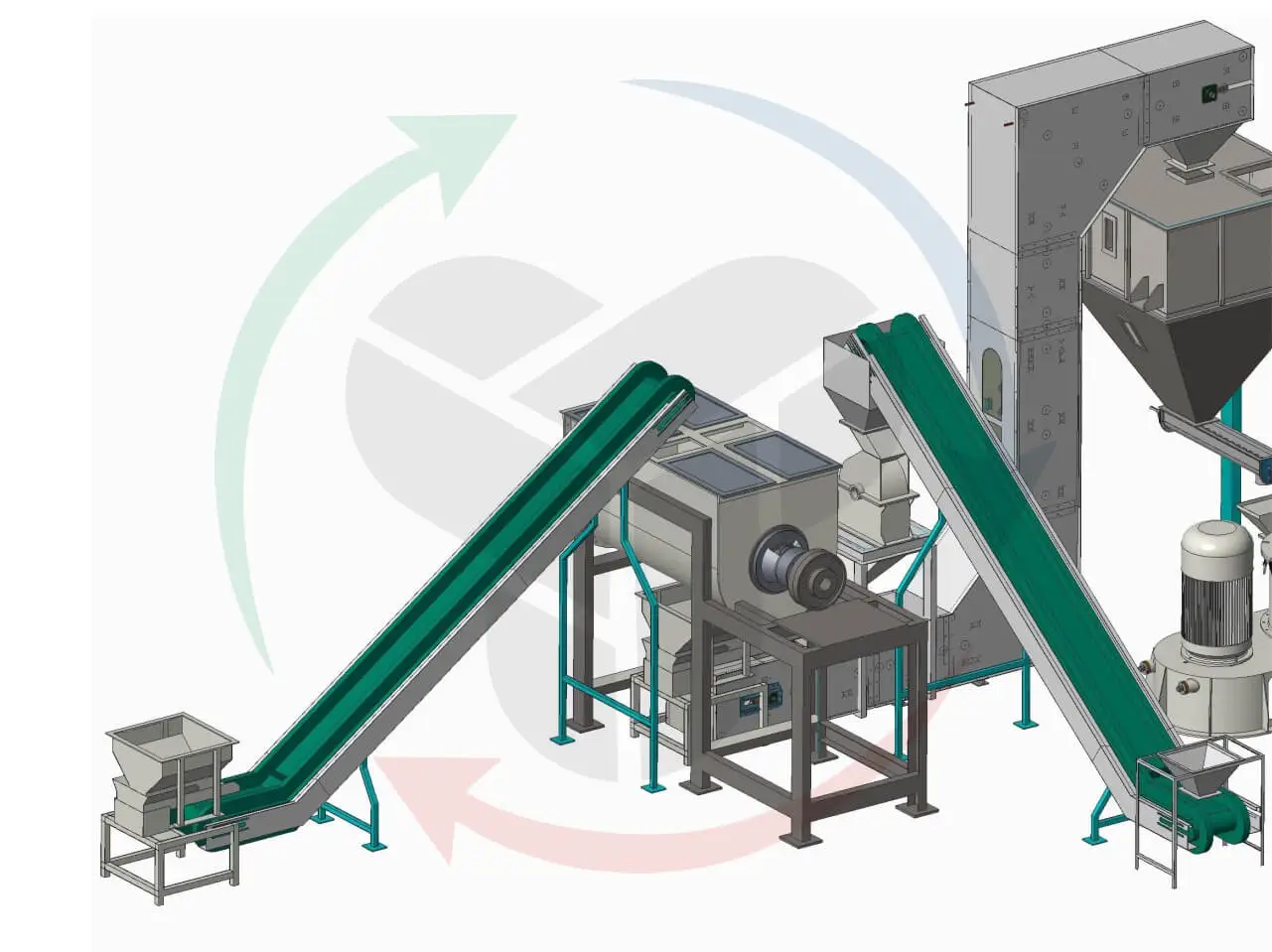

"SOLUTION FOR MATERIAL HANDLING EQUIPMENT"

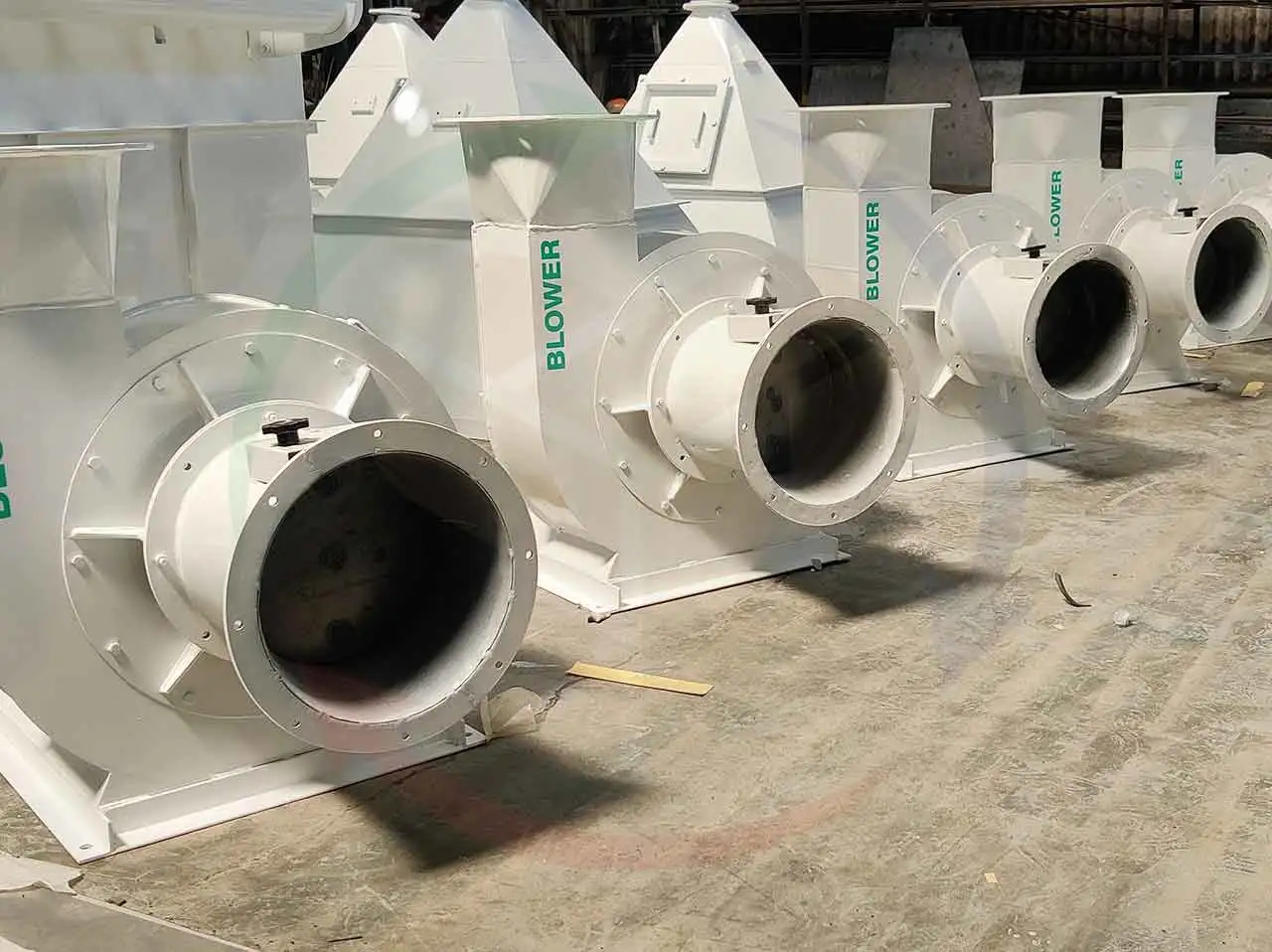

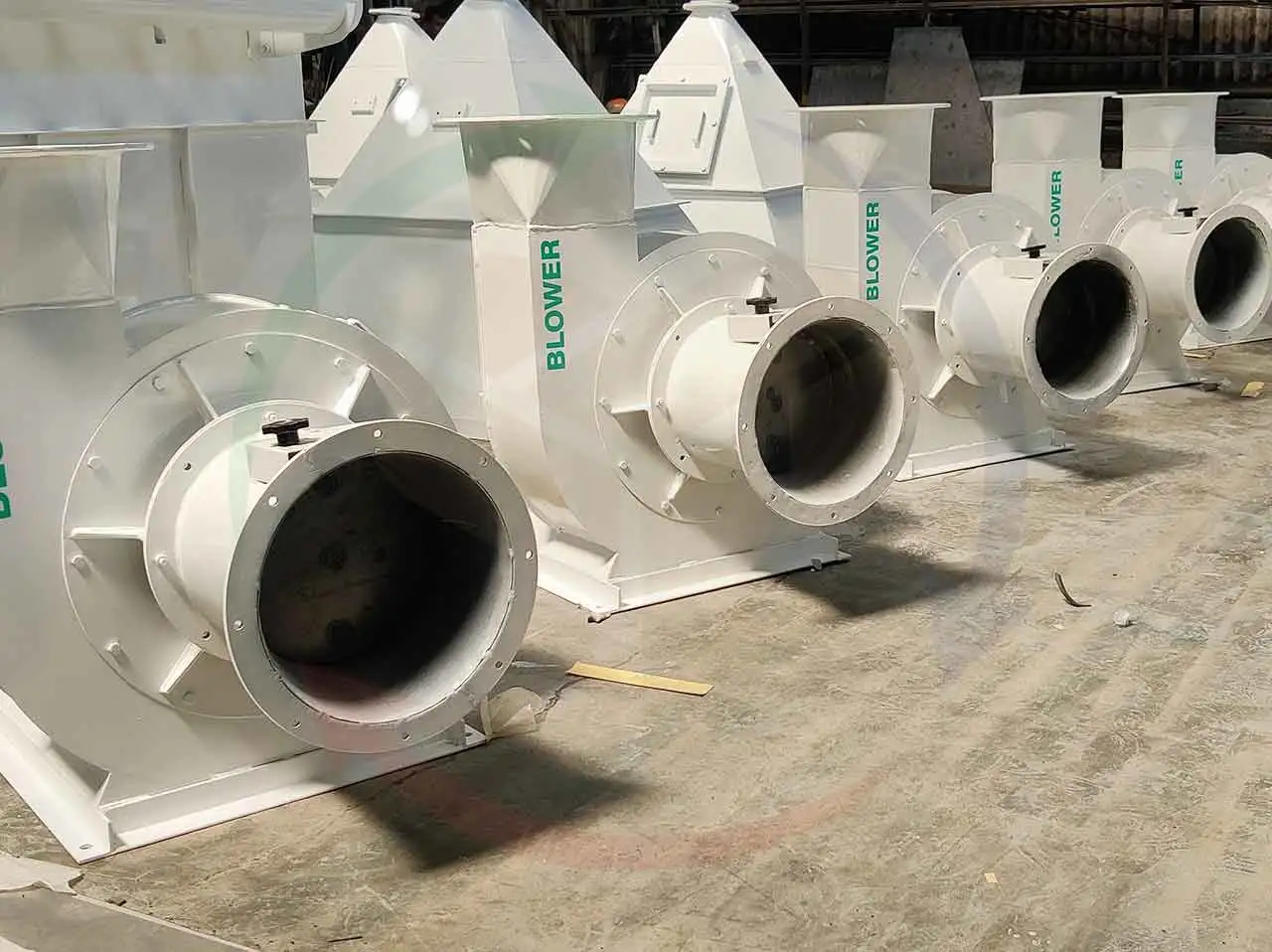

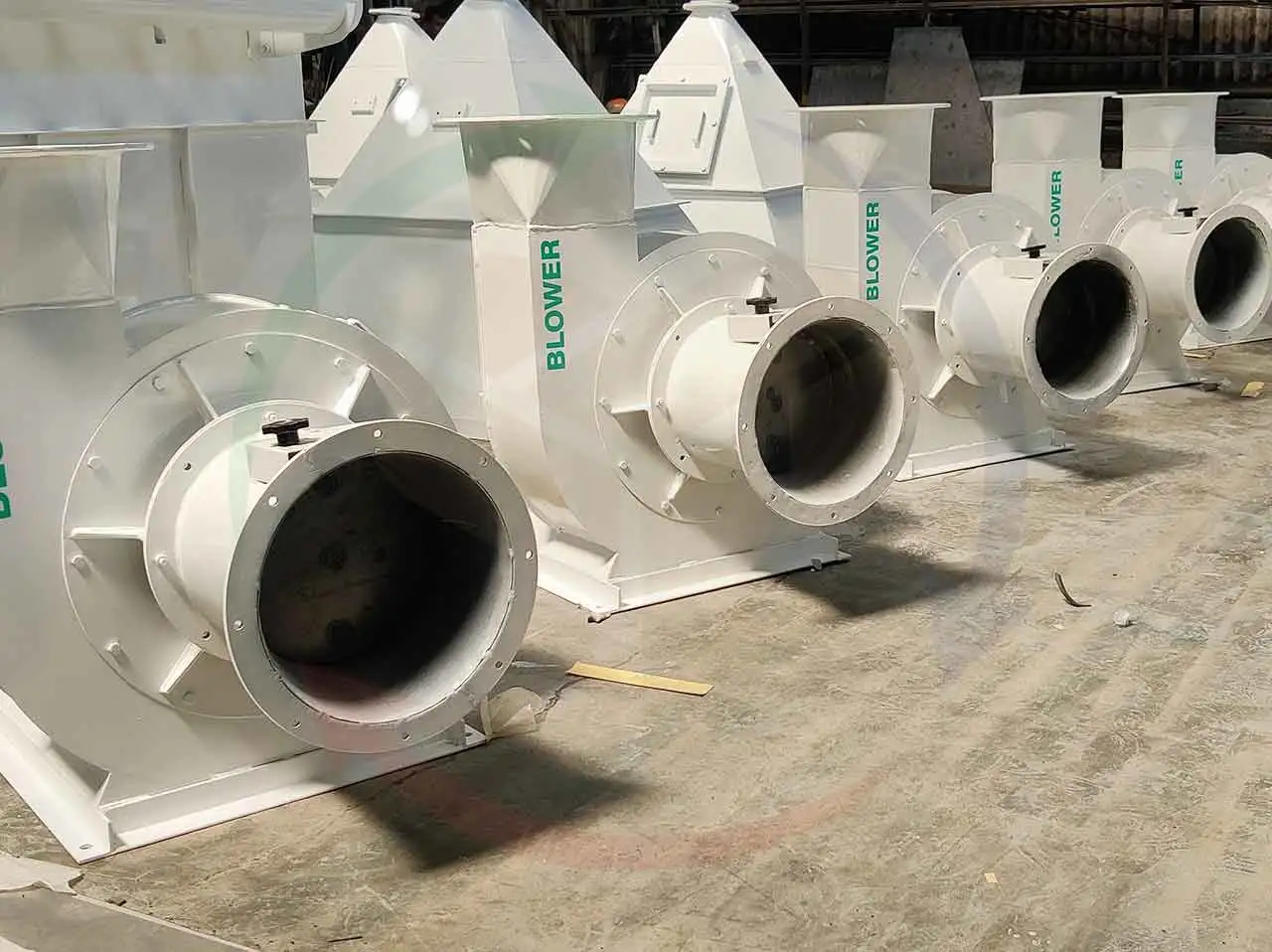

"SOLUTION FOR DUST COLLECTING SYSTEM"

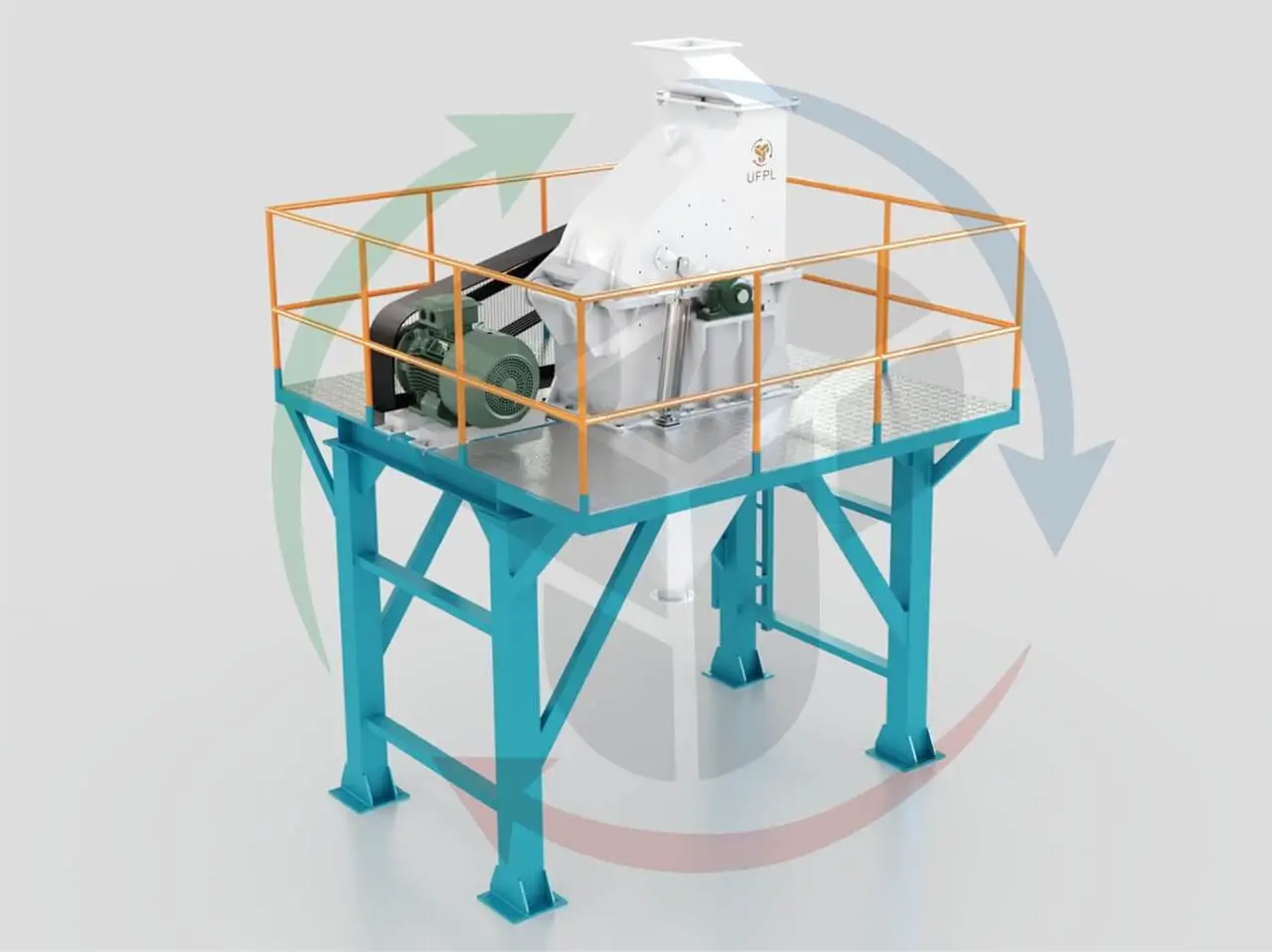

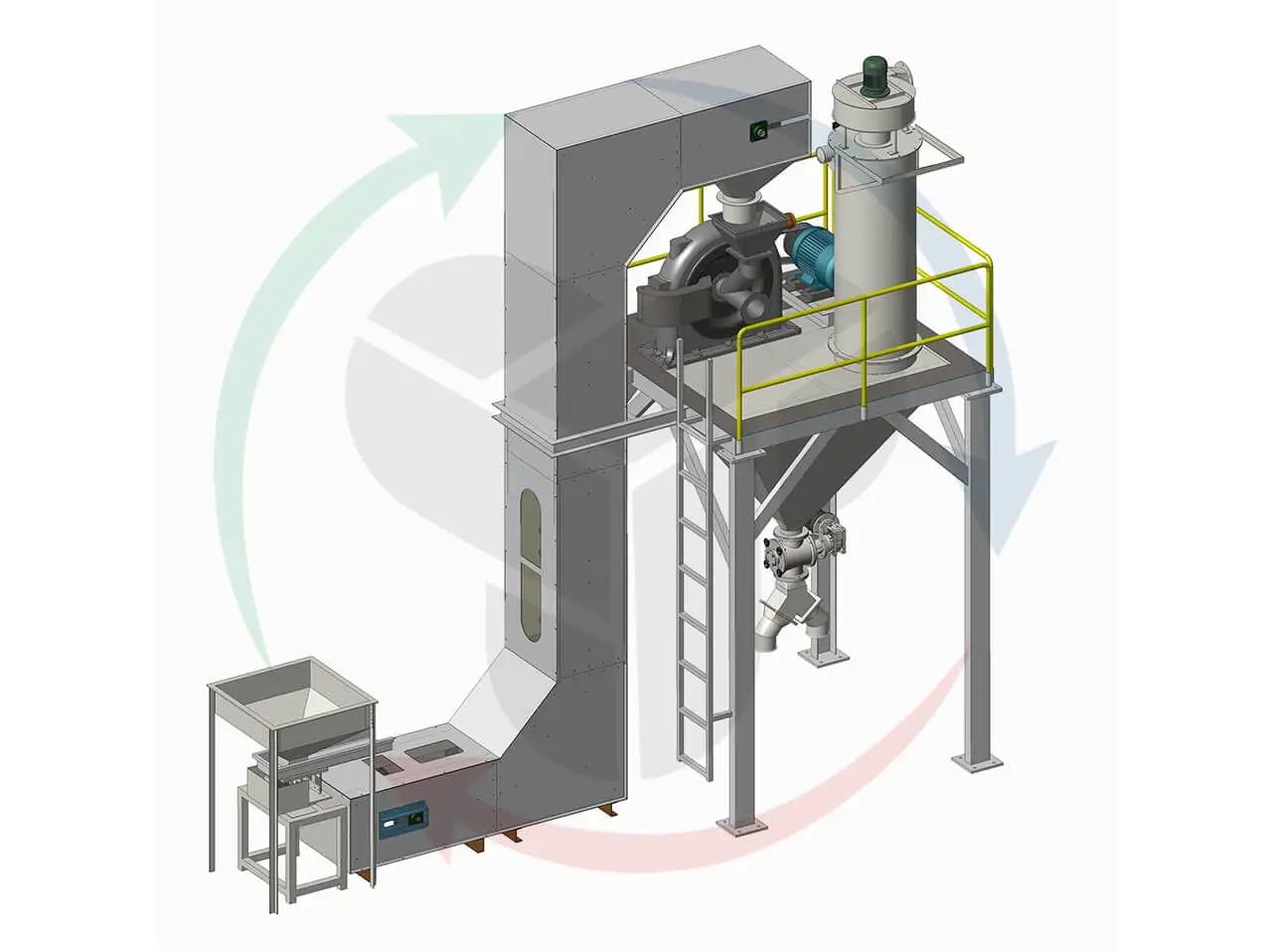

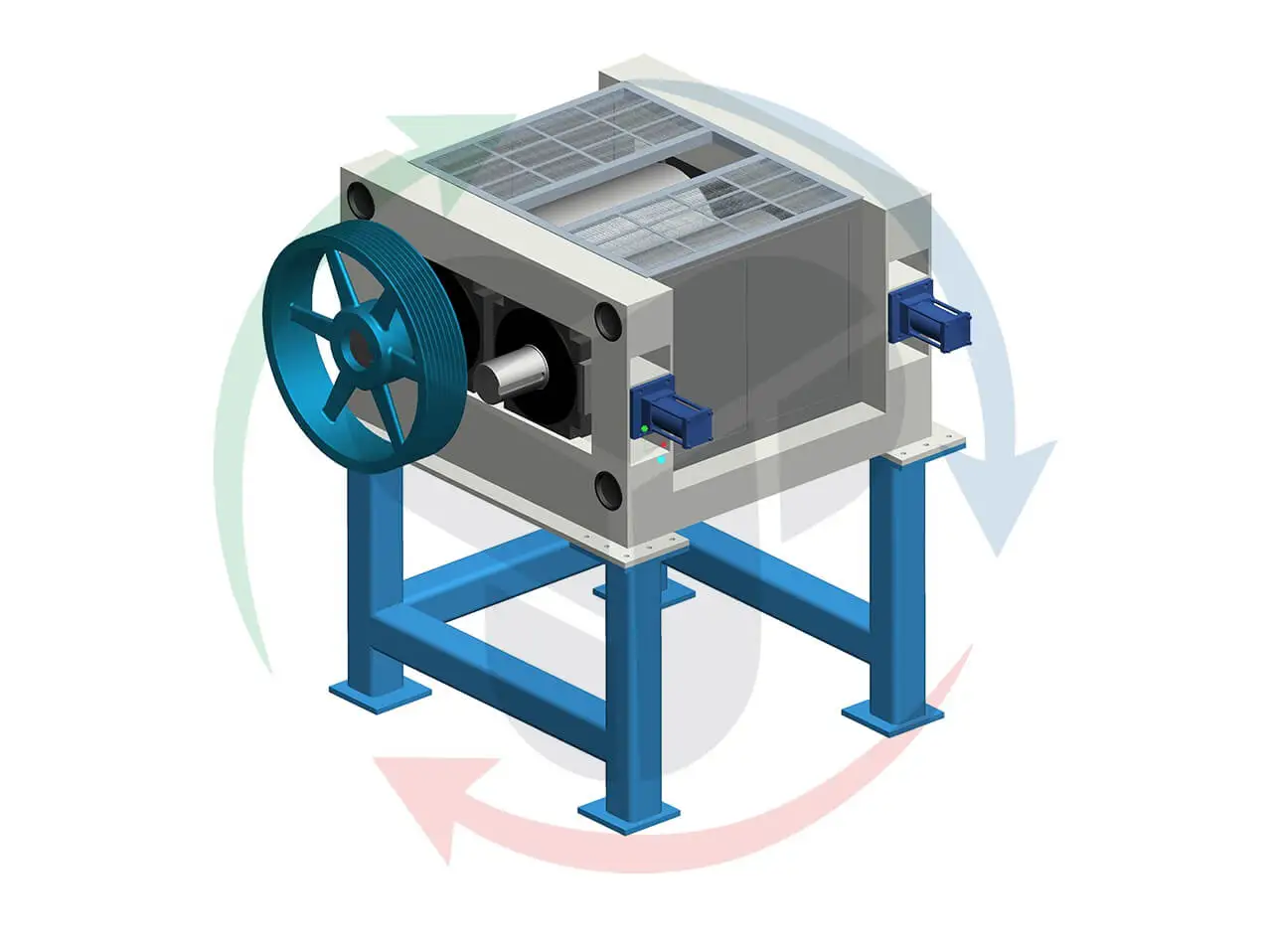

Size Reduction Equipment

Material Handling Equipment

"SOLUTION FOR SIZE REDUCTION EQUIPMENT"

- Quality

- Career

- Contact

- Home

- Products

Size Reduction Equipment

Material Handling Equipment

"SOLUTION FOR SIZE REDUCTION EQUIPMENT"

"SOLUTION FOR MIXING EQUIPMENT"

"SOLUTION FOR GRADATION EQUIPMENT"

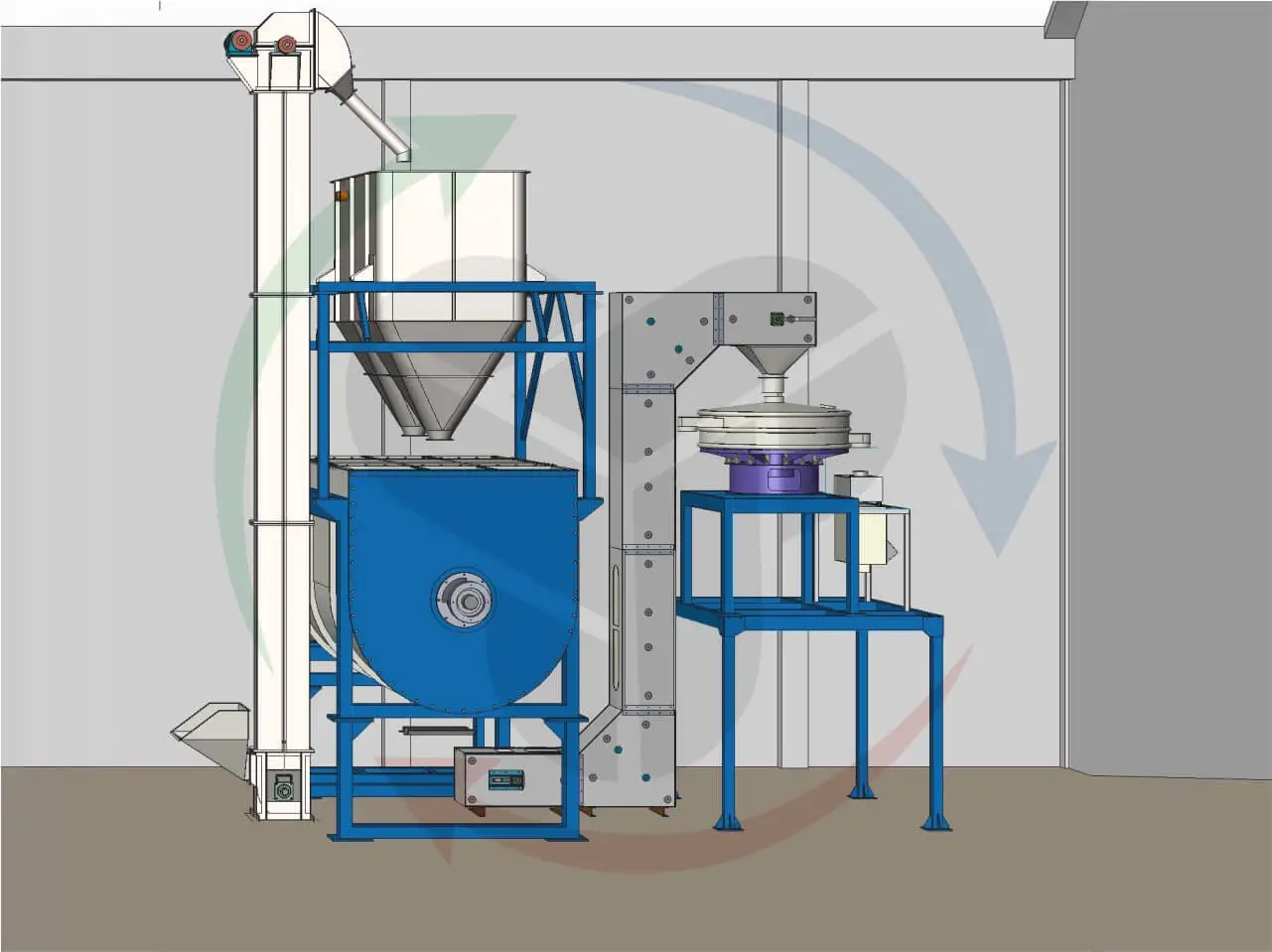

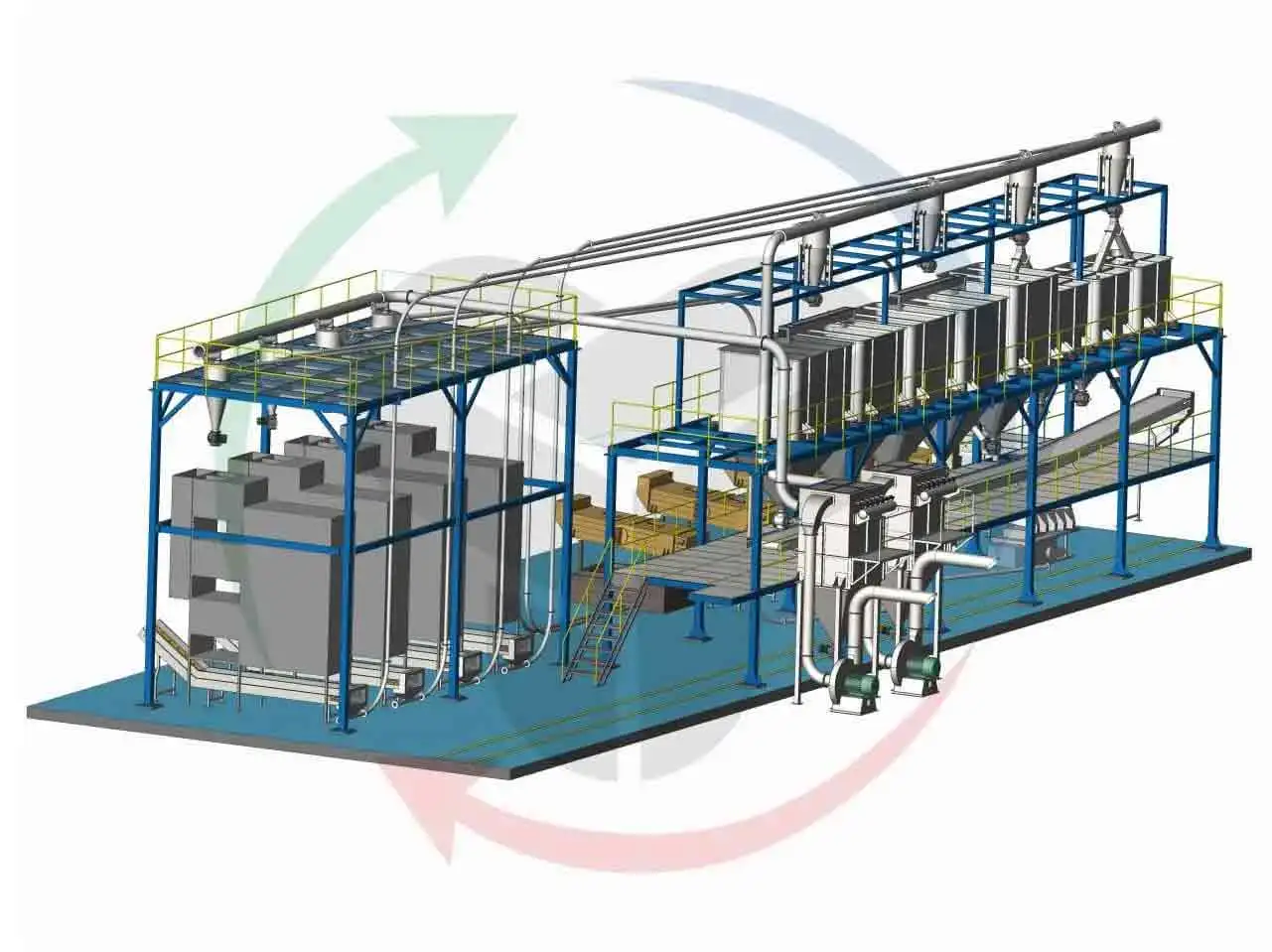

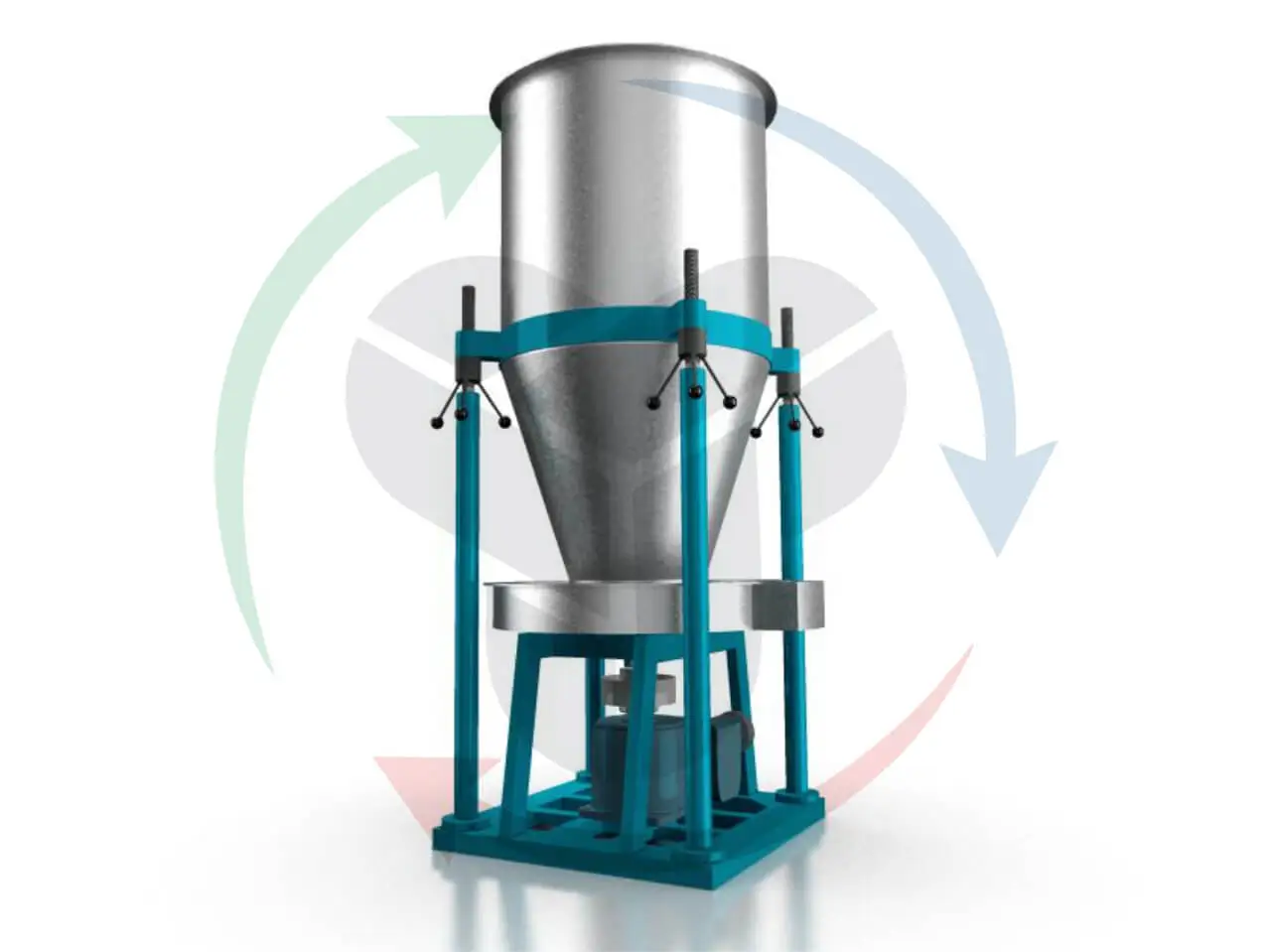

"SOLUTION FOR MATERIAL HANDLING EQUIPMENT"

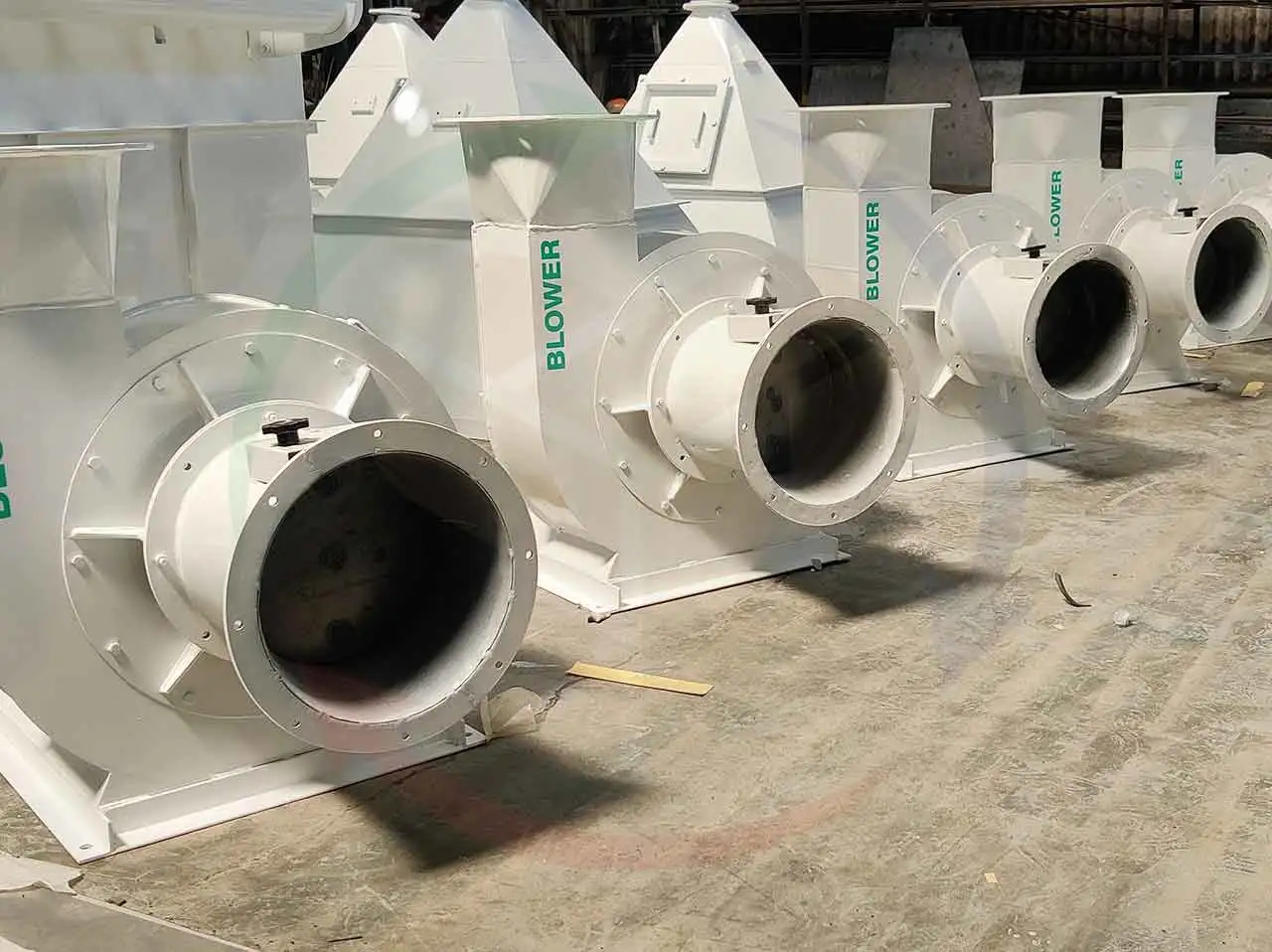

"SOLUTION FOR DUST COLLECTING SYSTEM"

Size Reduction Equipment

Material Handling Equipment

"SOLUTION FOR SIZE REDUCTION EQUIPMENT"

- Quality

- Career

- Contact